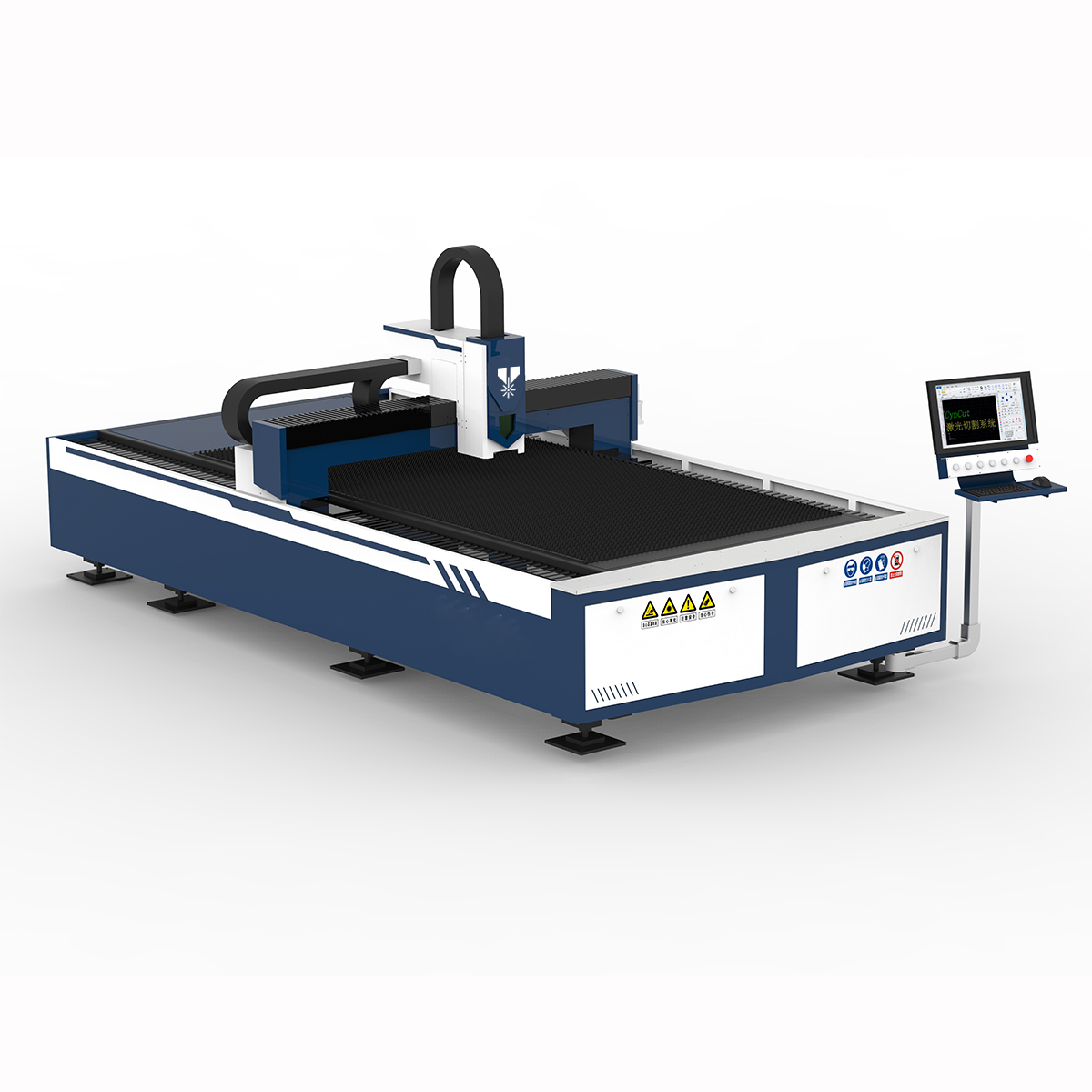

Economical Metal Fiber Laser Cutting Machine

This economical 3015 fiber laser metal cutting machine FL-S3015 is design by Fortune Laser for all kinds of metal sheet with affordable price. The 3015 laser cutter comes with Maxphotonics 1000W Laser source, professional CNC cutting system Cypcut 1000, OSPRI laser cutting head, Yaskawa servo motor, Schneider electronic components, Japan SMC Pneumatic components, and many other brand parts to ensure the quality cutting effect. The machine working area is 3000mm*1500mm. We can produce the machine based on your needs and projects, please feel free to contact us today!

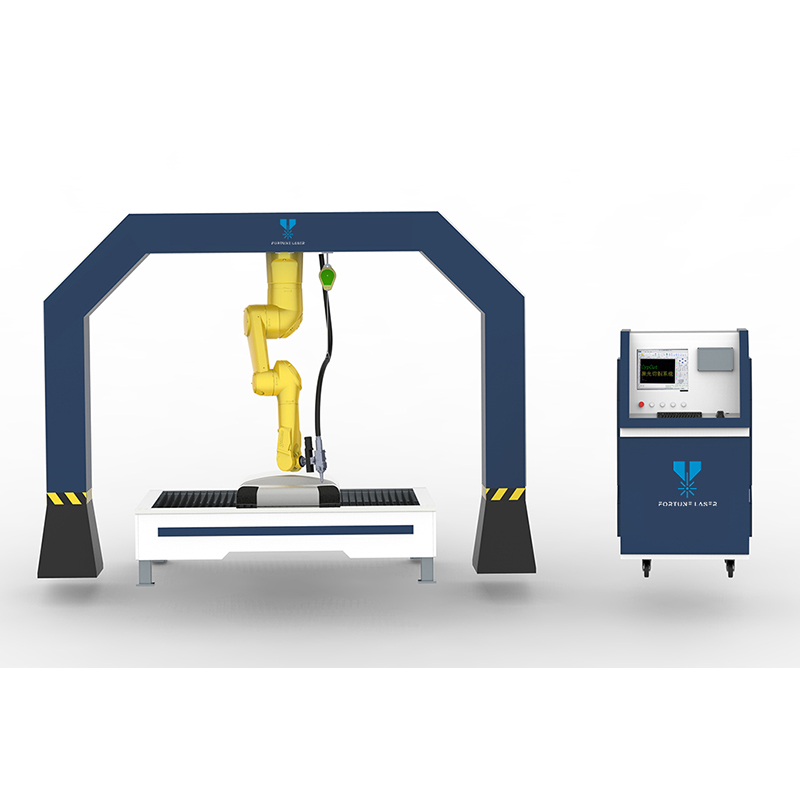

3D Robot Laser Cutting Machine with Robotic Arm

Fortune Laser 3D Robot Laser Cutting Machine is designed with an open structure. In the top center of the portal frame, there is a robotic arm to finish cutting operations at random points within the working table. The cutting precision reaches 0.03mm, making this cutter ideal for cutting metal sheets for automobiles, kitchen appliances, fitness equipment and many other products.

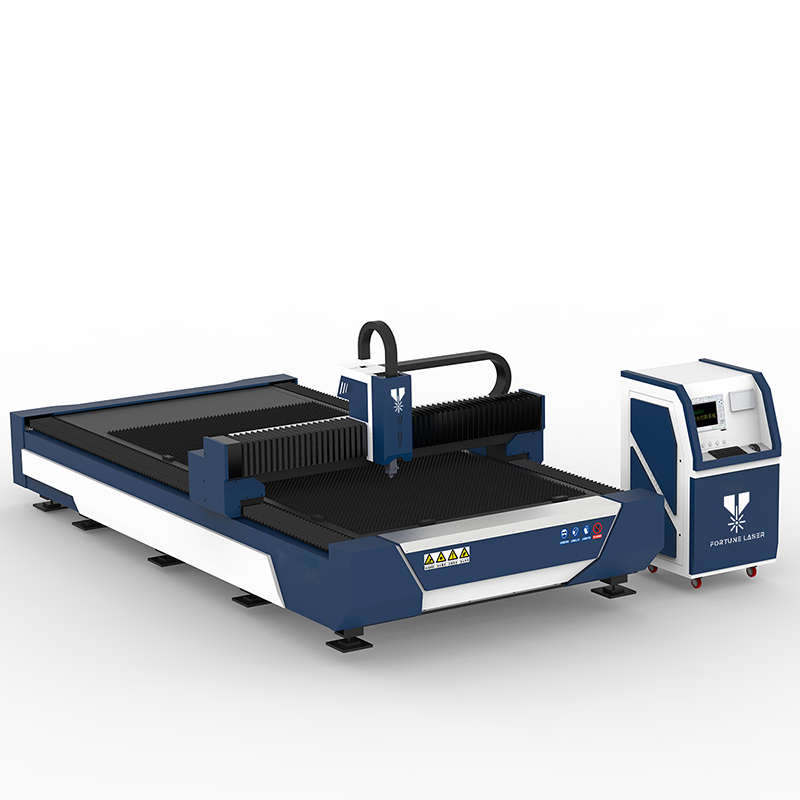

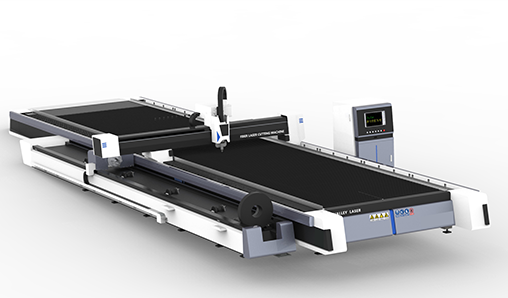

Open Type CNC Metal Sheet Fiber Laser Cutter

Fortune Laser open type CNC fiber laser cutter is a machine with super large working table. The working area can reach up 6000mm*2000mm. It is specially used for cutting all kinds of metal sheets. It is easy for users to operate and maintain. Also, the strict assembly process ensures the stable operation of the machine with high cutting precision. Fortune optical fiber laser cutting machine provides users with powerful cutting ability and efficiency with imported top-grade accessories, which is a good choice for users to process economic types.

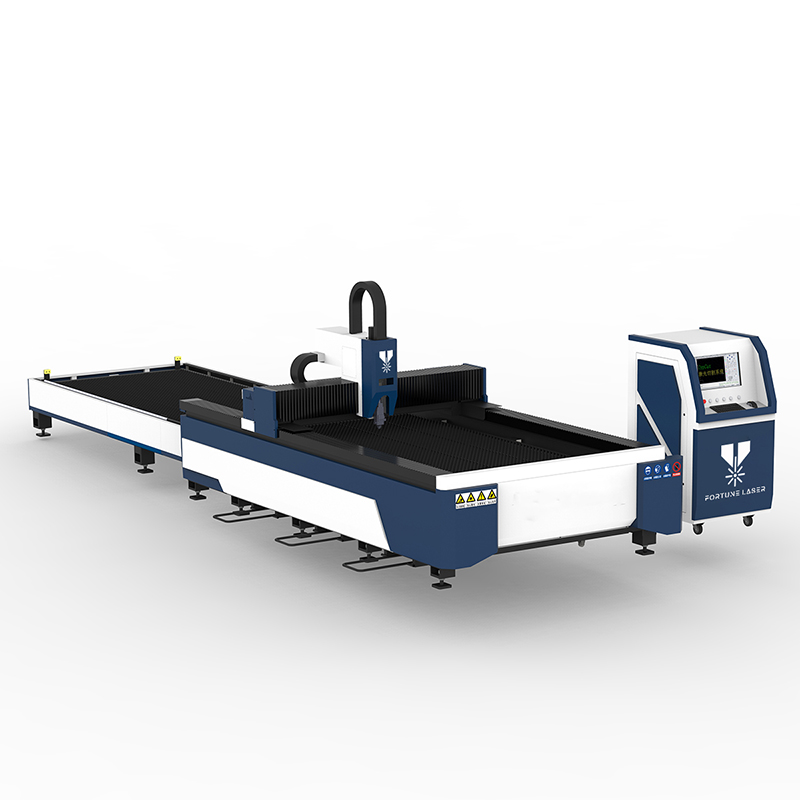

Laser Cutting Machine with Exchange Table

Fortune Laser Metal Laser Cutting Machine with Exchange Table is equipped with two cutting pallets that can be automatically switched quickly. When one is used for cutting, the other one can be loaded or unloaded with metal sheets. This greatly saves the loading and unloading time, improves the working efficiency and saves cost. The metal laser cutter provides high cutting efficiency and precision, clean, smooth cutting, low material loss, no burr, small heat-affected zone and nearly no thermal deformation. The laser machines are very suitable for large-scale continuous processing and is the preferred equipment for metal fabricators.

Large Format Industrial Metal Optical Fiber Laser Cutting Machine

Fortune Laser High Power Large Format Industrial Metal Optical Fiber Laser Cutting Machine is a high-performance industrial laser cutting tool that adopts the latest advances in laser technology for high speed and accurate cutting on sheet metals and large-sized profile steel. The machines are suitable for large format metalworking pieces. It works well with a wide range of metal materials like carbon steel, stainless steel, mild steel, aluminum, copper, brass, and alloy, etc. . The fiber laser cutting machine includes a cooling, lubricating and dust...

High Power Fiber Laser Cutter 6KW~20KW

Fortune Laser high-power fiber laser cutting machine 6KW-20KW, is equipped with world leading fiber laser source which generates powerful laser that focuses on the objects and lead to instant melting and evaporation. Automatic cutting is controlled by numerical control system. This hi-tech machine integrates advanced fiber laser technology, numerical control and precision machinery technology.

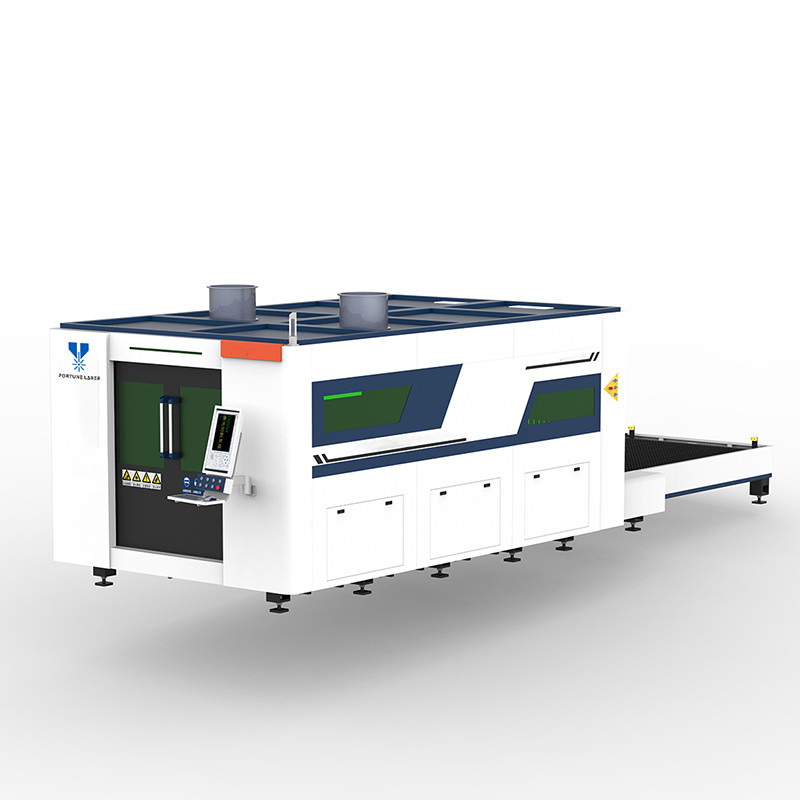

Fully Enclosed Metal CNC Laser Cutter Machine

Fortune Laser fully enclosed fiber laser cutting machine adopts fully enclosed laser protective cover, chain exchange platform and professional CNC cutting system to provide users with powerful cutting ability and efficiency. At the same time, the top imported parts and strict assembly process ensure the machine safe, efficient and high-precision stable operation.

Dual-use Sheet and Tube Laser Cutting Machine

Fortune Laser fully enclosed fiber laser cutting machine adopts fully enclosed laser protective cover, chain exchange platform and professional CNC cutting system to provide users with powerful cutting ability and efficiency. At the same time, the top imported parts and strict assembly process ensure the machine safe, efficient and high-precision stable operation.

Automatic Feeding Laser Tube Cutting Machine

Fortune Laser Automatic Feeding Laser Tube Cutting Machine is a high-precision, high-efficiency and high-reliability cutting equipment that combines computer control, precision mechanical transmission, and thermal cutting. The good design man-machine interface makes the operation more convenient and simple, and can cut out various blanks quickly and accurately. It adopts one-piece modular design, which makes it easy to install and easy to move.

Precision Fiber Laser Cutting Machine

FL-P Series precision laser cutting machine is designed and made by FORTUNE LASER. Adopted with leading laser technology for thin sheet metal application. The machine is combined with marble and Cypcut laser cutting system. With Integrated designing, dual gantry linear motor (or ball screw )driving system, friendly interface and long term stable working