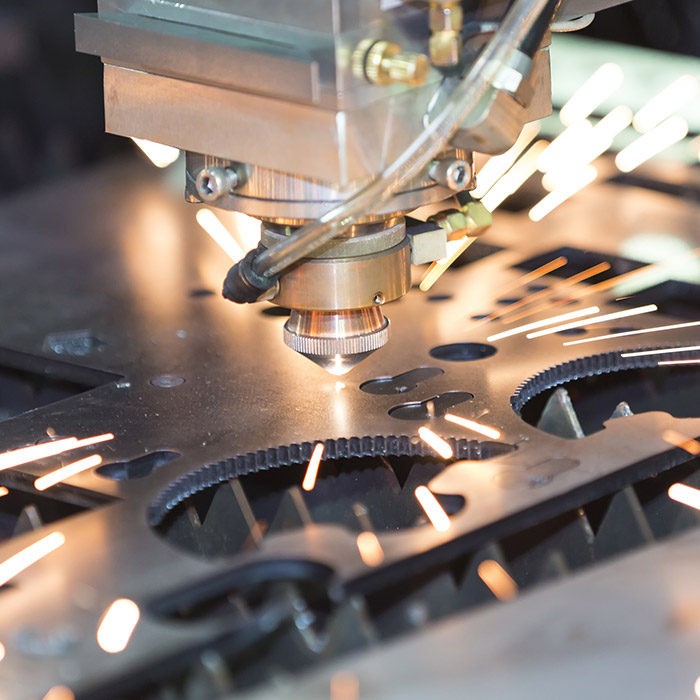

Laser cutting , also known as laser beam cutting or CNC laser cutting, is a thermal cutting process that is frequently used in sheet metal processing.

When choosing a cutting process for a sheet metal fabrication project, it’s important to consider the capabilities of the tool you choose based on the needs of your project. For many fabrication projects using sheet metal, laser cutting is a better choice. Here are some advantages for laser cutting machines you need to know.

Relatively Lower Cost

Compared to other cutting methods, laser cutting is very cost effective. With the CNC automation system involved, labor costs are minimal, and the machines are very easy to operate. Additionally, laser doesn’t get dull or worn like other cutting tools do. For this reason, there is no necessary changeover mid-process, leading to better productivity and shorter lead time. When there are minimal interruptions in the cutting process, costs will be lower.

High Speed and Efficiency

Lasers can cut through materials very quickly. The exact speed will depend on the laser power, material type and thickness, tolerances and the intricacy of the parts. However, they move very quickly compared with other cutting tools. In addition to fast cutting speeds, laser cutters can work for a long time, increasing the overall efficiency of the cutting process.

Automation / CNC Control

One of the advantages of laser cutting is that the machines are entirely run by CNC controls, which leads to parts and products with little to no variation and significantly fewer defects. Automation also means that less labor is necessary to operate the machine and carry out its tasks, making the process more efficient. Automation of the cutting process leads to greater efficiency, higher quality products, and much less waste of leftovers. Besides the 2D cutting, the laser cutters are also suitable for 3D cutting. The machines are good fit for the creation of prototypes, models and molds, pipe, tube, corrugated metals, expanded metal, flat sheet stock, and more.

High Precision

Laser cutters have highly detailed capabilities, able to create small cuts and tight tolerances. They create clean, sharp, and smooth edges and curves. High cut finish. They will also produce little (even no) burring because the laser melts the material, rather than cutting it. Laser cutters are a great fit for sheet metal processing because they are highly precise and will create accurate, high-quality cuts.

The cost of operation, speed of the machine, and easy operation of CNC control make laser cutters a good fit for most size products and projects. Because laser cutters are accurate and precise, you can be sure that the end result is of high quality. Laser cutters can cut through a wide variety of metal materials, including aluminum, brass, copper, mild steel, carbon steel, stainless steel, etc. making it an ideal option for sheet metal fabrication. The machines can handle tight tolerances and intricate designs, ensuring that any project is within their reach.

Welcome to contact Fortune Laser for more details about the metal laser cutting machines for your sheet metal fabrication project today!

HOW CAN WE HELP TODAY?

Kindly fill out the form below and we'll get back to you as soon as possible.