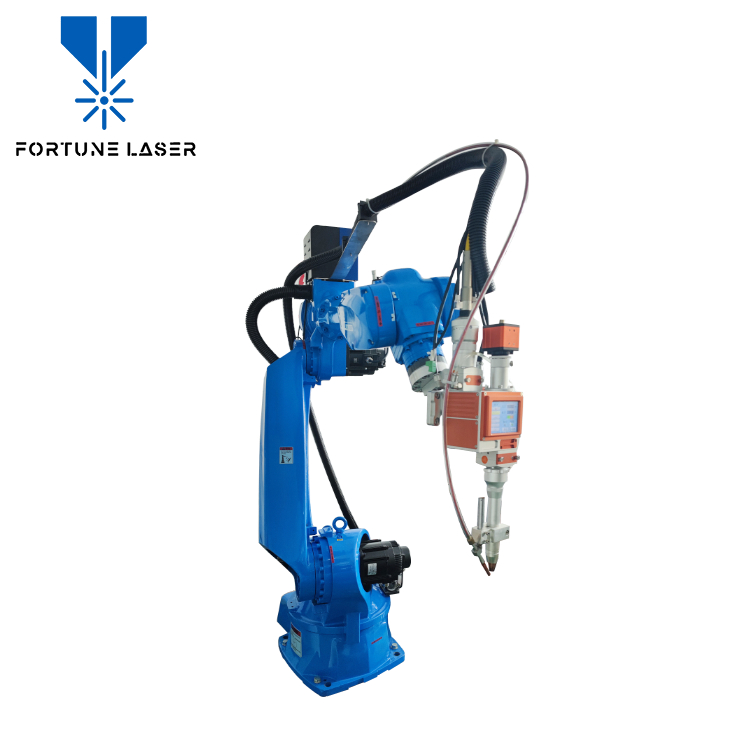

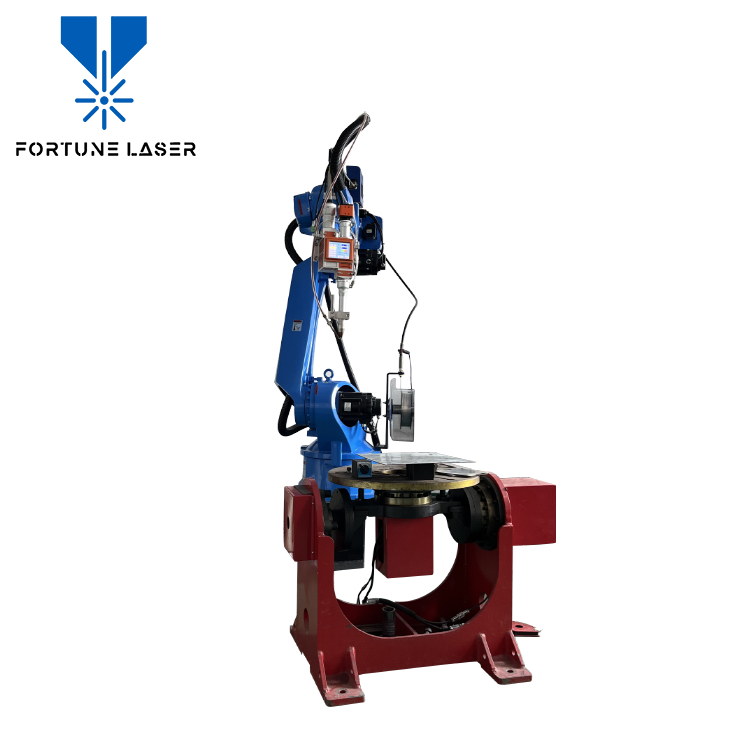

Fortune Laser Automatic Robot Arm frame 6 Axis Cnc Laser Welding Machine

Fortune Laser Automatic Robot Arm frame 6 Axis Cnc Laser Welding Machine

The principle of robot welding

The robot laser welding machine is mainly composed of a robot system and a laser host. It works by heating the welding material with a laser beam, causing it to melt and join together. Because the laser beam has a highly concentrated energy, it can quickly heat and cool the weld seam, so as to achieve high-quality welding results.

The beam control system of the robot laser welding machine has very high precision and stability. It can adjust the position, shape and power of the laser beam according to the welding needs, achieving perfect control during the welding process. At the same time, the robot system can realize automatic operation without manual intervention, which greatly improves the welding efficiency and quality.

Application of robotic laser welding machine

Robot Laser Welding Machine Features

Fortune Laser Robot Laser Welding Machine Technical Parameters

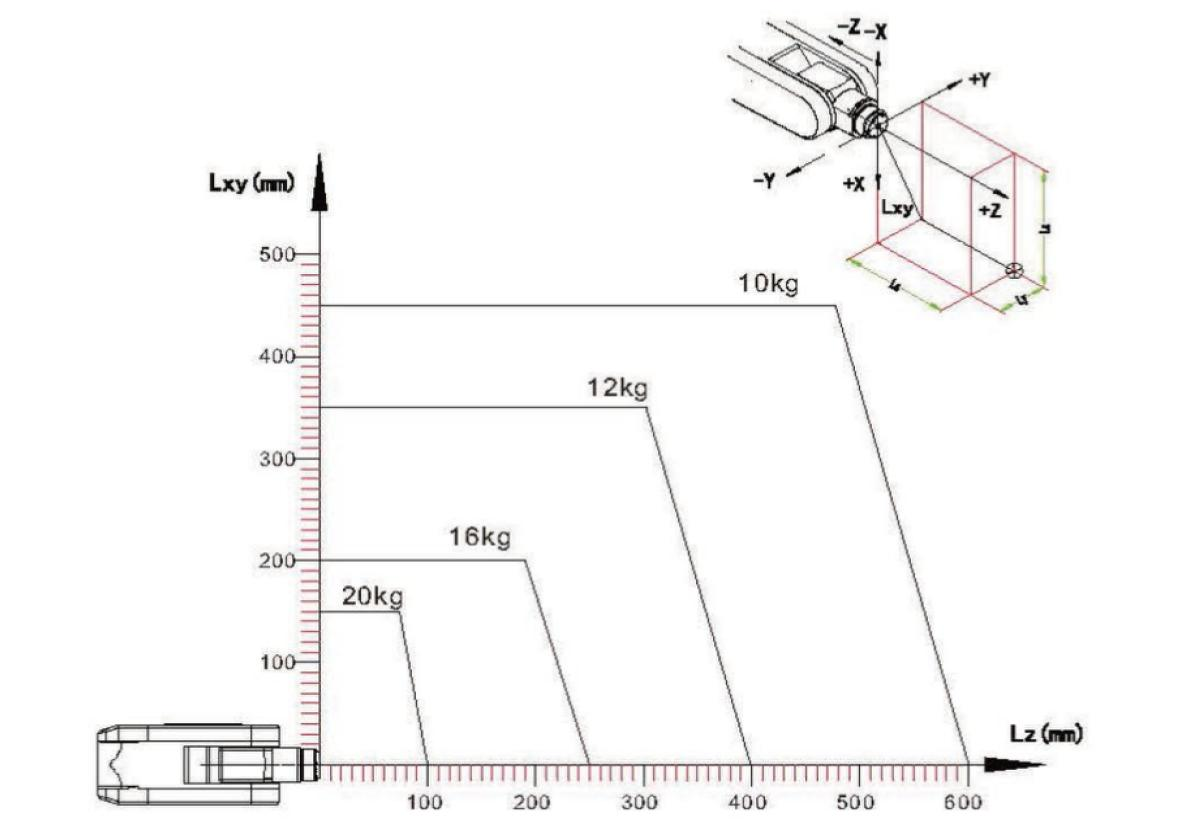

Robot load graph

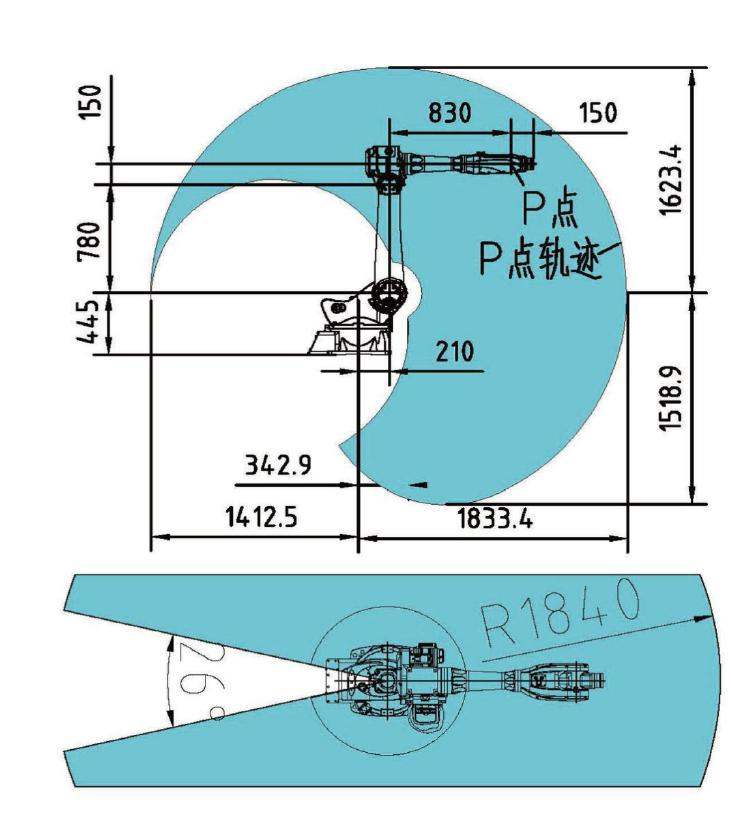

Dimensions and action range Unit: mm P point action range

Operate the remote

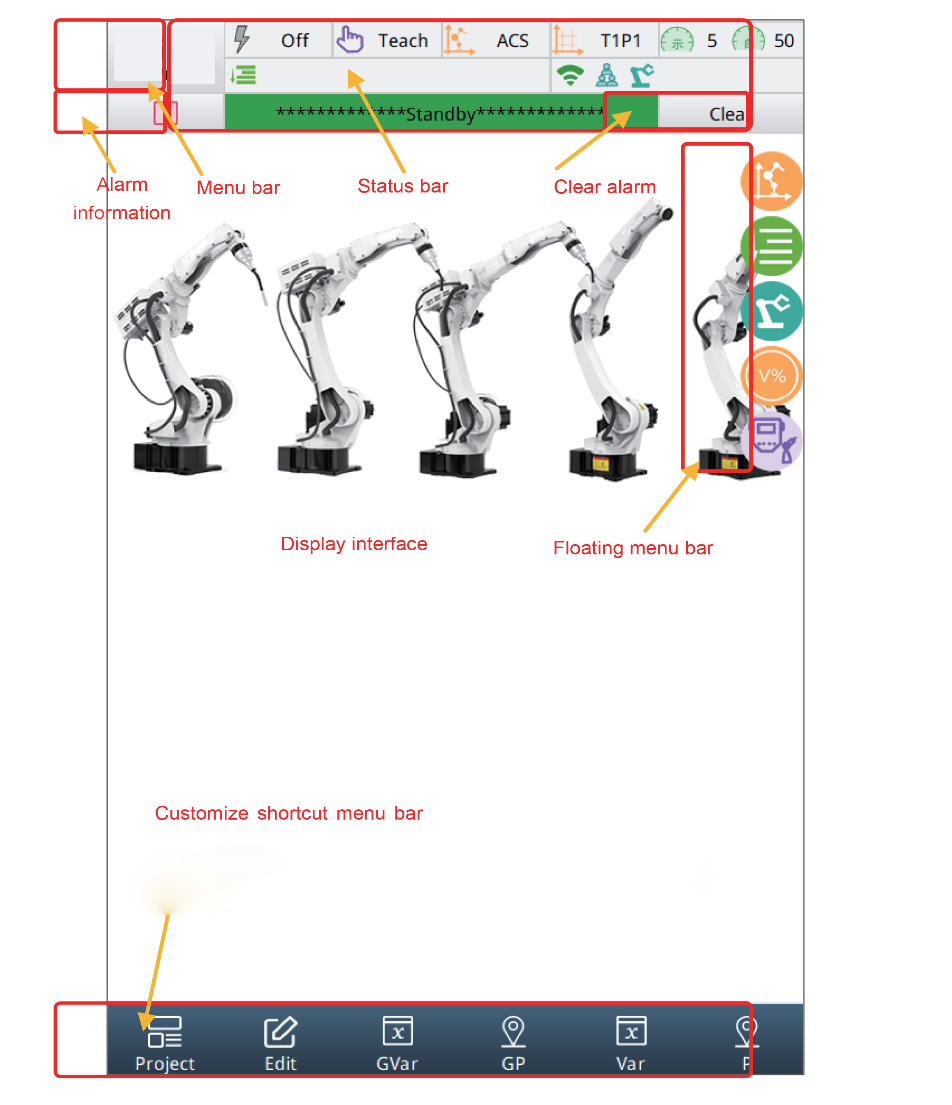

Main Interface

Control Cabinet

Considerations for choosing a laser welding robot

Video

Ask Us for A Good Price Today!

Write your message here and send it to us