Fortune Laser 200W Gold Silver Copper Jewelry YAG Laser Welding Machine with Microscope

Fortune Laser 200W Gold Silver Copper Jewelry YAG Laser Welding Machine with Microscope

Working principle of jewelry welding machine

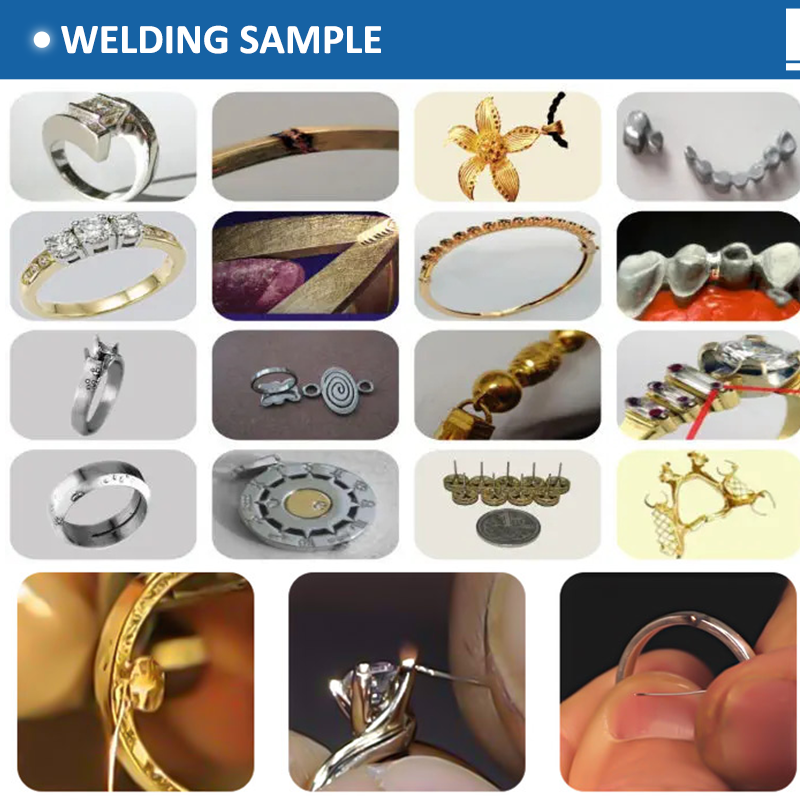

Jewelry has always been an enduring industry. People's pursuit of jewelry has always been to keep improving, but exquisite jewelry is often quite troublesome to make. With the advancement of technology, traditional jewelry craftsmen are gradually missing. Because of its complicated process, it is difficult to The grinding method makes the processing cost high and the efficiency low, and the appearance of the laser spot welding machine reduces the processing procedure of the jewelry industry, making jewelry processing a worthwhile leap.

Laser spot welding machine is a kind of laser material processing equipment. The laser welding machine uses high-energy laser pulses to locally heat the material in a small area. The energy of the laser radiation gradually diffuses into the interior of the material through heat conduction. After reaching a certain temperature, a specific molten pool is formed to achieve the purpose of welding.

Jewelry is a very small part in the process of processing and polishing. The xenon lamp of the jewelry laser welding machine is mainly lit by the laser power supply and illuminates the YAG crystal rod. At the same time, the pump of the jewelry laser welding machine can have a certain power of laser energy through the half mirror and full mirror, and then optimize the laser quality by the beam expander and reflect the output laser through the galvanometer, which can be directly welded on the material component.

200W Jewelry Laser weldingMachine Features

● Light workbench, fast welding speed and high efficiency.

● Imported ceramic concentrating cavity, corrosion resistance, high temperature resistance, high photoelectric conversion efficiency, xenon lamp life of more than 8 million times.

● Quantity, pulse width, frequency, spot size, etc. can be adjusted within a large range to achieve a variety of welding effects. The parameters are adjusted by the control rod in the closed chamber, which is simple and efficient.

● The advanced automatic shading system eliminates eye irritation during working hours.

● With 24-hour continuous working ability, the whole machine has stable working performance and is maintenance-free within 10,000 hours.

● Humanized design, ergonomics, working for a long time without fatigue.