Fortune Laser pulse Laser cleaning Machine

Fortune Laser pulse Laser cleaning Machine

What Is Pulse Laser Cleaning Machine?

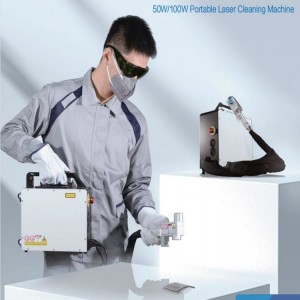

Fortunelaser Laser cleaning machine is the latest high-tech product. Easy to install, operate, easy to achieving automation. Plug in power, turn on and start cleaning - without chemicals, media, dust, water.

Cleaning with no detergent, no media, no dust, no water. Auto focus, can clean curved surface, gentle cleaning surface. Cleaning resin, oil stain, rust, coating materials, paints on workpiece surface.

What is the difference between a pulsed laser and a continuous laser?

Fiber laser source

(The laser source is divided into continues laser source and pulsed laser source in operation)

Pulsed laser source:

refers to a pulse pf light emitted by a laser source in a pulsed working mode.in short ,it is like the work of a flashlight.When the switch is closed and then immediately turned off,a “light pulse”is send out.Therefore,the pulses are one by one,but the instantaneous power is very high and the duration is very short.It is necessary to work in pulse mode,such as sending signals and reducing heat generation.The laser pulse can be extremely short and has an excellent effect in the field of laser cleaning machines,it does not damage the substrate of the object.The single pulse energy is high,and the effect of removing paint and rust is good.

Continuous laser source:

The laser source continues to provide energy to produce a laser output for a long time.Thus obtaining continuous laser light.Continuous laser output power is generally relatively low.Starting at 1000w.It is suitable for laser metal rust removal.The main feature is that is burns the surface and cannot whiten the surface of the metal.After cleaning the metal,there is a black oxide coating.In addition,it has a good effect for cleaning non-metallic surfaces.

In short:The best way to clean various workpieces (such as paint removal,rust removal,oil removal,etc)is to use a pulsed laser source.

Laser Cleaner Technical Parameters from Fortune Laser

| Model | FL-C100 | FL-C200 | FL-C500 | FL-C1000 | FL-C2000 |

| Laser Power | 100W | 200W | 500W | 1000W | 2000W |

| Cooling Way | Air Cooling | Air Cooling | Water cooling | ||

| Laser Wavelength | 1064 nm | ||||

| Power Supply | AC 220-250V / 50 Hz | AC 380V / 50 Hz | |||

| Maximum KVA | 500W | 2200W | 5100W | 7500W | 14000W |

| Fiber Length | 3m | 12-15m | 12-15m | 12-15m | 12-15m |

| Dimension | 460x285x450mm | 1400X860X1600 mm | 2400X860X1600mm+ | ||

| 555X525X1080mm (external chiller size) | |||||

| Focal length | 210mm | ||||

| Focal depth | 2mm | 5mm | 8mm | ||

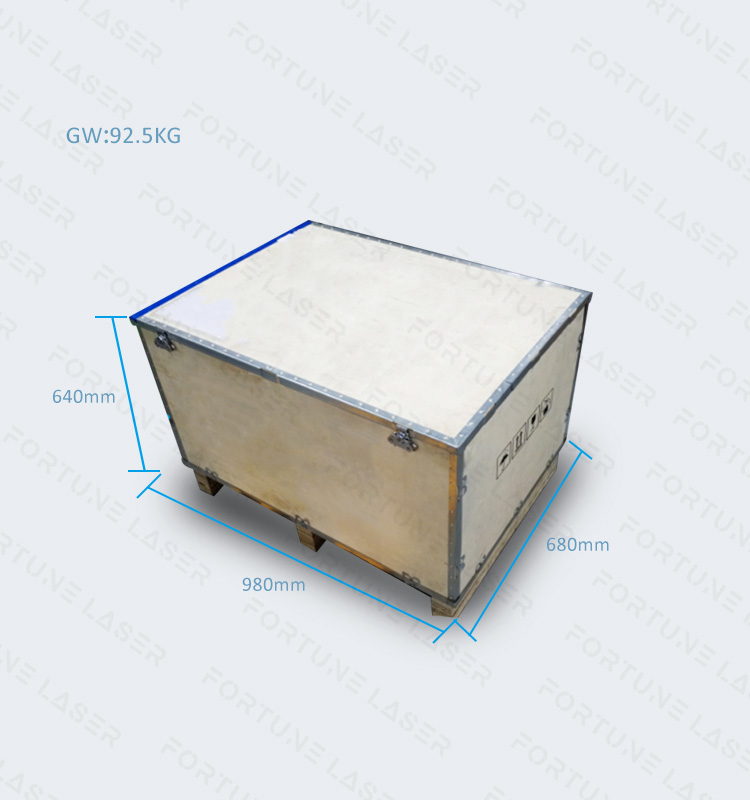

| Gross Weight | 85kg | 250kg | 310kg | 360kg | Total 480kg |

| Handheld Laser Head Weight | 1.5kg3 kg | ||||

| Working Temperature | The service life of the laser is long at constant temperature of 5-40 ° C (normally at constant temperature of 25 ° C) | ||||

| Pulse width | 20-50k ns | ||||

| Scan Width | 10mm-80mm (customizable additional price) | ||||

| Laser frequency | 20-50k HZ | ||||

| Laser source type | Fiber laser source | ||||

| Options | Portable/ Handheld |

Handheld/ Automation/ Robotic system |

Handheld/ Automation/ Robotic system |

Handheld/ Automation/ Robotic system |

Handheld/ Automation/ Robotic system |

Comparison of laser cleaning and other processes

|

Laser cleaning |

Chemical cleaning |

Mechanical grinding |

Dry ice cleaning |

Ultrasonic cleaning |

|

Cleaning method |

Laser,non-contact |

Chemical cleaning agent, contact type |

sandpaper, contact |

Dry ice, non-contact |

Cleaning agent, contact type |

|

Workpiece damage |

no |

yes |

yes |

no |

no |

|

Cleaning efficiency |

High |

low |

low |

medium |

medium |

|

Consumables |

Only electricity |

Chemical cleaning agent |

sandpaper, grinding wheel |

dry ice |

Special cleaning agent |

|

cleaning effect |

spotlessness |

general, uneven |

general, uneven |

excellent, uneven |

Excellent, small range |

|

Safety/environmental protection |

No pollution |

polluted |

polluted |

No pollution |

No pollution |

|

manual operation |

Simple operation, handheld or automated |

The process flow is complex, and the requirements for operators are high |

Labor-intensive, protective measures are required |

Simple operation, handheld or automated |

Simple operation, need to manually add consumables |

|

cost input |

High initial investment cost, no consumables, low maintenance cost |

Low initial investment and high cost of consumables |

High initial investment and low cost of consumables |

The initial investment is medium, and the cost of consumables is high |

Low initial investment and high cost of consumables |

Features of the laser cleaning

1. Simple software , select prestored parameters directly.

2. Prestore all kinds of parameter graphics, six kinds of graphics can be selected: straight line/spiral/ circle/rectangle/rectangle filling/Circle filling.

3. Easy to use and operate.

4. Simple interface.

5. 12 different modes can be switched and selected quickly to facilitate production and debugging.

6. The language can be English/Chinese or other languages (as required).

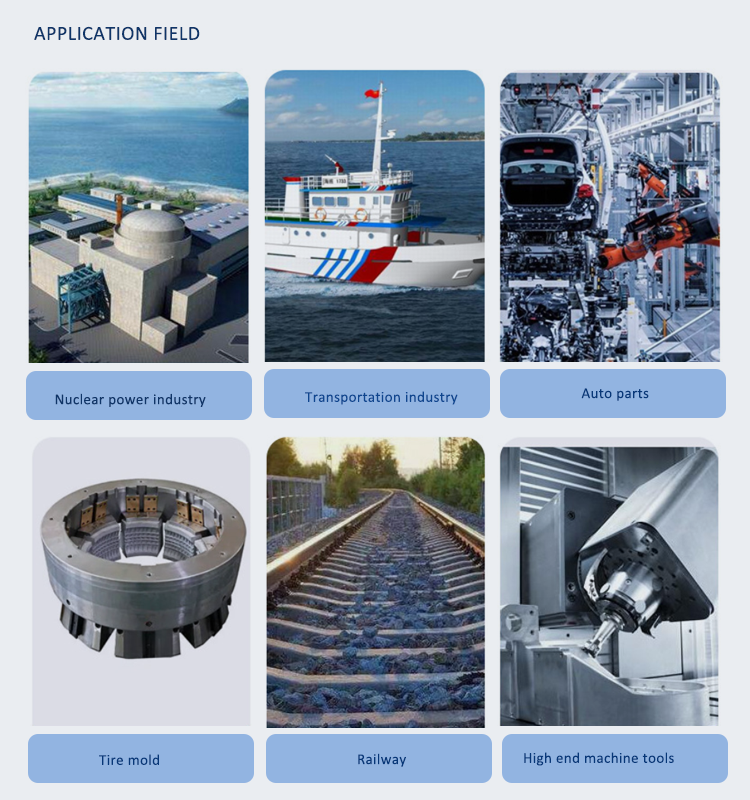

Application Fields of Laser Cleaning Machine

Rust Remove, Deoxidation,Coating removal,Stone surface repair,wood cleaning.

Cleaning of all metal materials, including copper, aluminum, stainless steel, carbon steel and other metal materials mixed with paint and rust.

Cleaning of metal molds,metal pipe tube cleaning.