Fortune Laser CW 1000W/1500W/2000W cleaning width 650mm large format cleaning machine

Fortune Laser CW 1000W/1500W/2000W cleaning width 650mm large format cleaning machine

Application of laser cleaning machine in industrial manufacturing

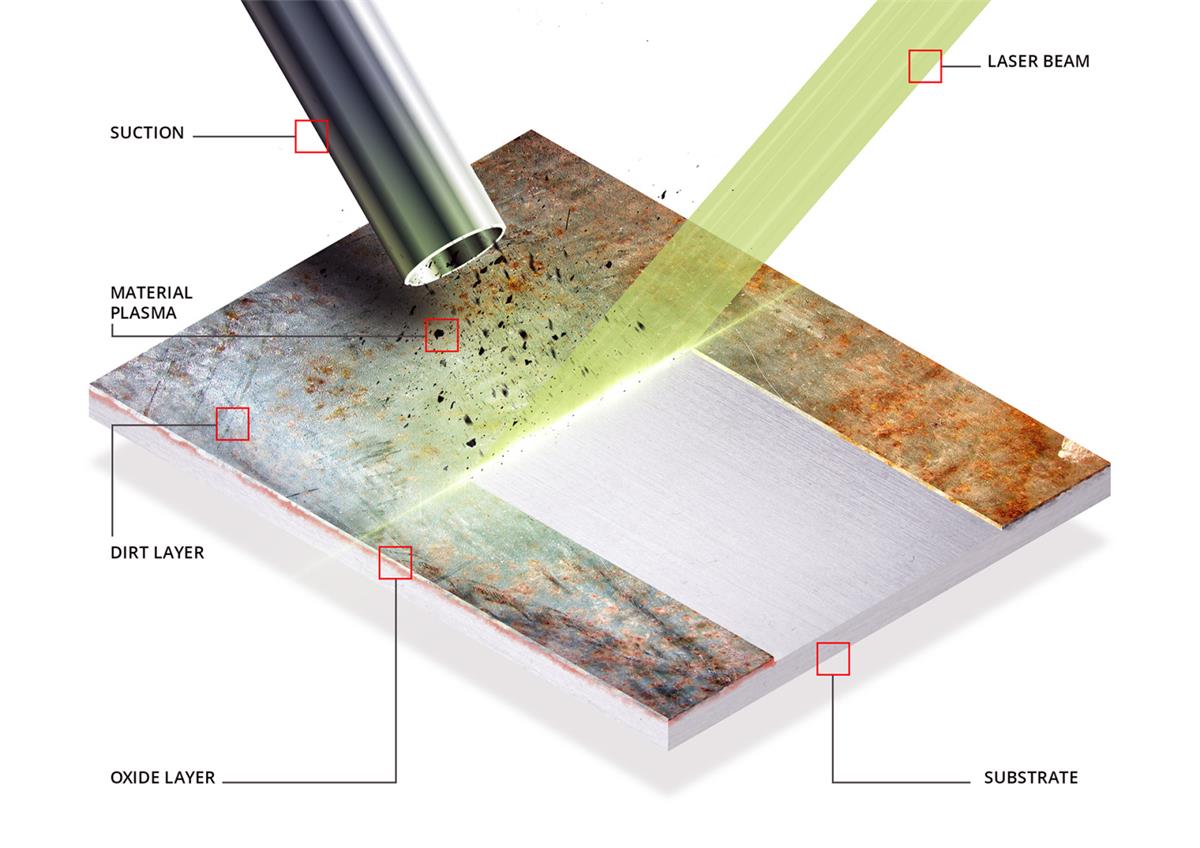

In the process of industrial production and manufacturing, in order to ensure the quality of the product, it is necessary to clean the stains, oil stains, rust and other pollutants on the surface of the product. The traditional sandblasting and abrasive cleaning methods have caused great pollution and damage to the environment and the material itself, which is not conducive to later maintenance and use. Now the application of new laser cleaning technology makes cleaning in industrial manufacturing easier.

1000W 1500W 2000W Laser Cleaning Machine Features

Fortune Laser Mini Laser Cleaning Machine Technical Parameters

Main configuration

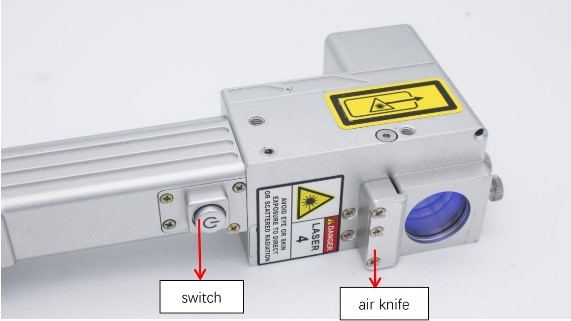

● The dual purpose laser head Handheld and automatic, 2D laser head. Easy to hold and integrate with automation; easy to operate and has various functions;

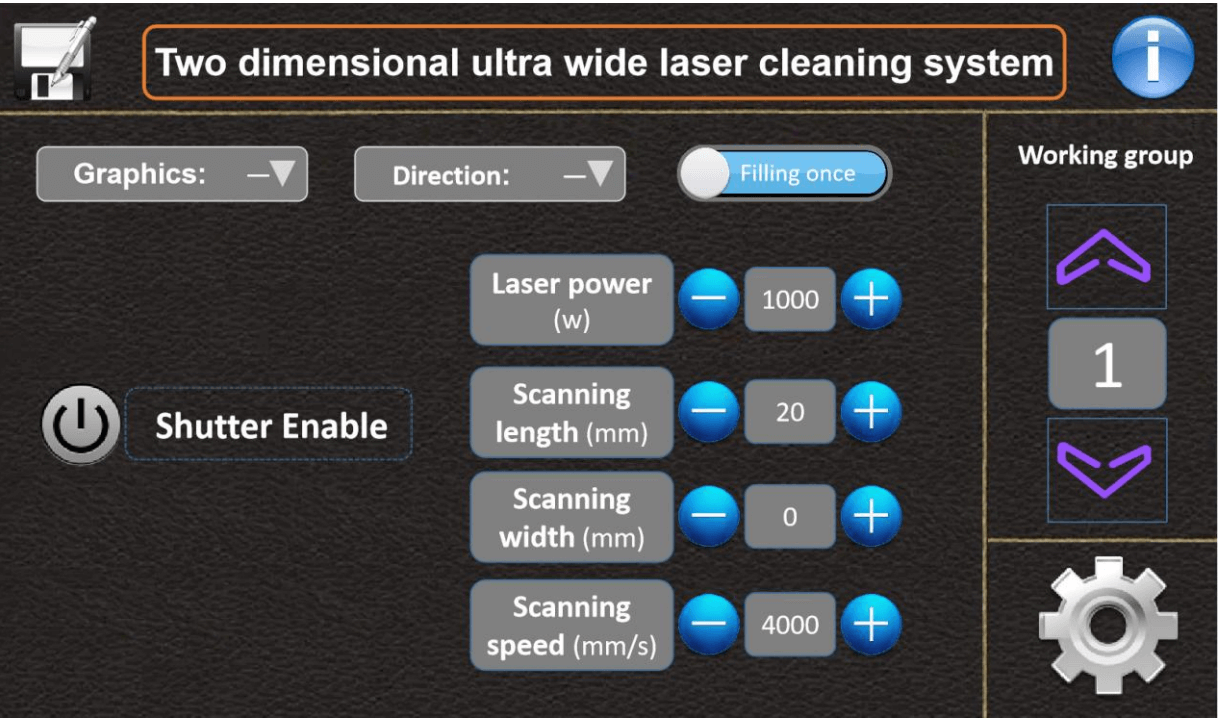

● AIMPLE SOFTWARE

PRESTORE OF VARIOUS PARAMETER GRAPHICS

1. Simple software select prestored parameters directly

2. Prestore all kinds of parameter graphic six kinds of graphics can be selected straight line/spiral/ circle/rectangle/rectangle filling/Circle filling

3. Easy to use and operate

4. Simple interface

5. The language can be English/Chinese or other languages(if required)

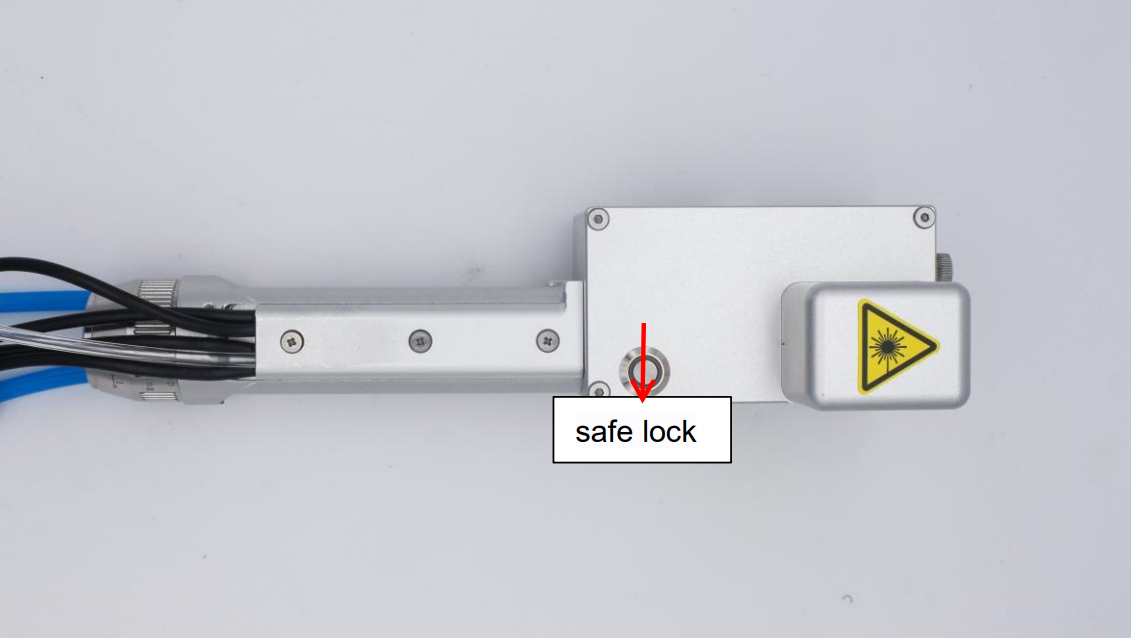

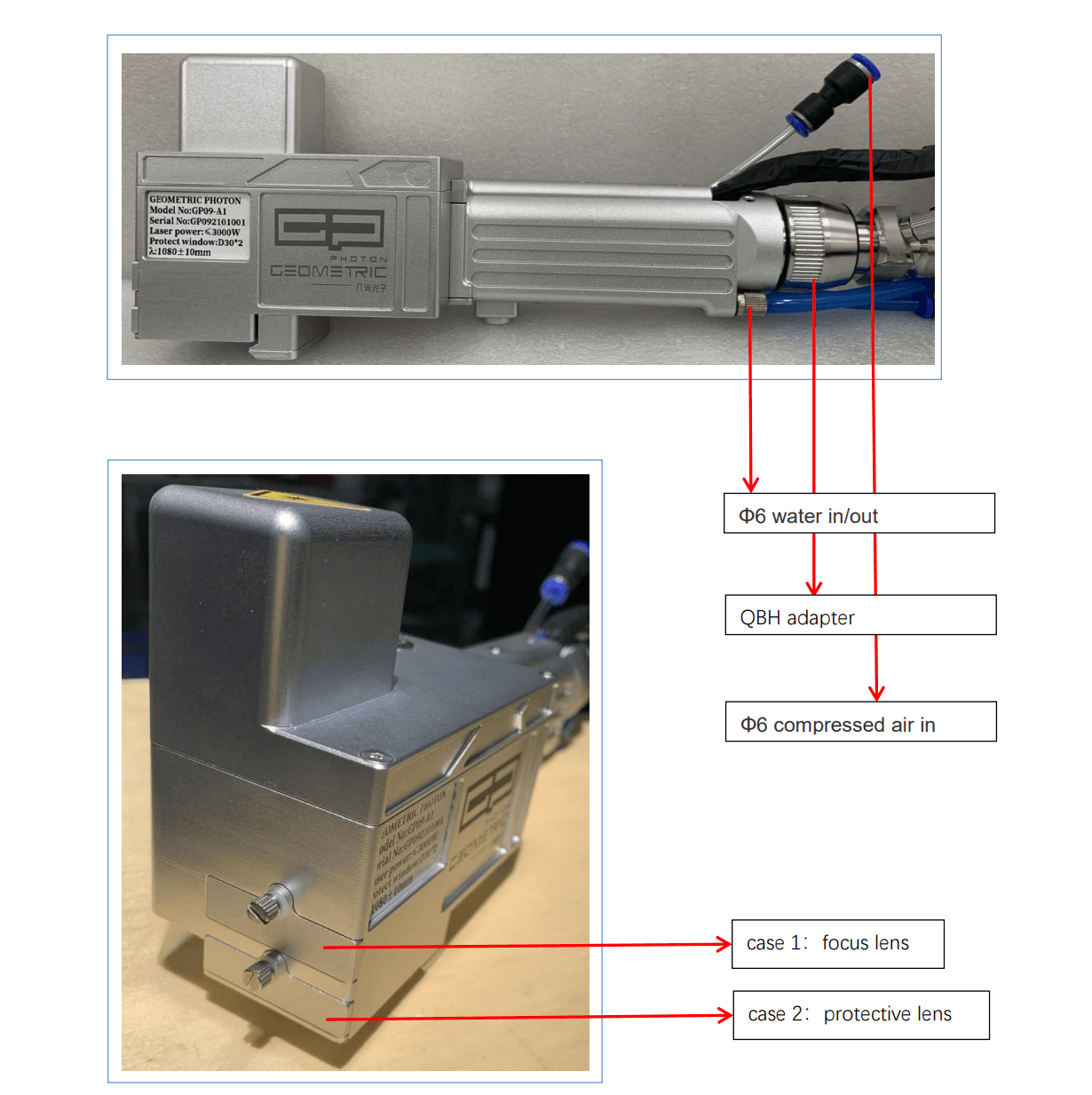

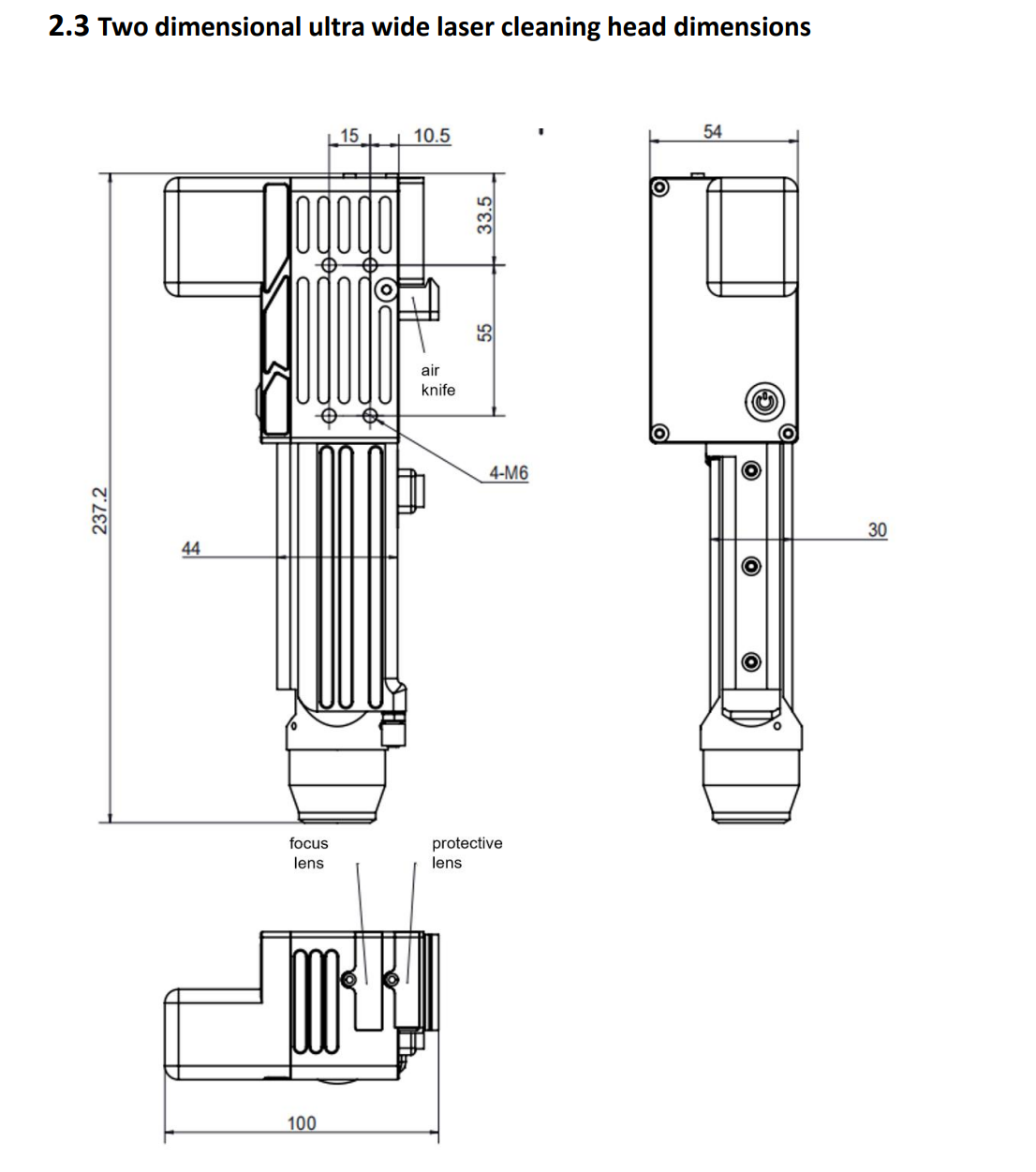

2D Laser Head Introduce

Press the main switch of the screen and press the safety switch, and the red light will swing to preview. If you need to change the graphics and other parameters, you need to enter the password to enter the advanced interface. Note: After pressing the safety lock, the emission permit switch is in the open state, and then press the control switch, the light can be emitted.

|

Interface type |

QBH |

|

Power range |

≤3000W |

|

Optical maser waveleng |

1080nm |

|

Collimation spot adjustment range |

≤8mm |

|

Galvanometer |

10mm |

|

Focus length |

D30/F800 |

|

Hand-held laser head weight |

900g |

Do you know 5 applications of laser cleaning machines in industrial manufacturing?

1. Cleaning in the electronics industry

The electronics industry uses lasers to clean oxidizing substances, and the electronics industry is suitable for using lasers to clean oxidizing substances. Before the circuit board is soldered, the component pins must be fully oxidized to ensure the electrical contact effect, and the pins must not be damaged during the decontamination process. Laser cleaning can meet the requirements of use, and the work efficiency is very high. A needle only needs to be irradiated with the laser once.

2. Pretreatment for brazing and welding.

Laser welding preparation is one of the many applications of laser cleaning, which is beneficial to clean the surface layer of metal and aluminum from contaminants such as ferrous and non-ferrous metals, lubricants, etc., in preparation for high-quality welding. It also ensures smooth and porosity-free brazed joints.

3. Cleaning the mold

Cleaning of tire molds during production must be safe and reliable to reduce downtime. Because the laser cleaning method can be connected through an optical fiber to clean the dead angle or difficult-to-clean parts of the mold caused by light, it is very convenient to use.

4. Cleaning of old aircraft paint

After the aircraft has been in operation for a period of time, the surface of the aircraft needs to be repainted, so it is necessary to find a way to remove the old paint. The traditional mechanical cleaning and painting method is easy to damage the metal surface of the aircraft, causing hidden dangers to the flight of the aircraft. It is not easy to damage the surface layer when using the washing machine.

5. Local cleaning coating

Laser cleaning can clean coatings and paints in industrial production such as automobiles, maintaining the integrity of the substrate material.

Handling of common exception

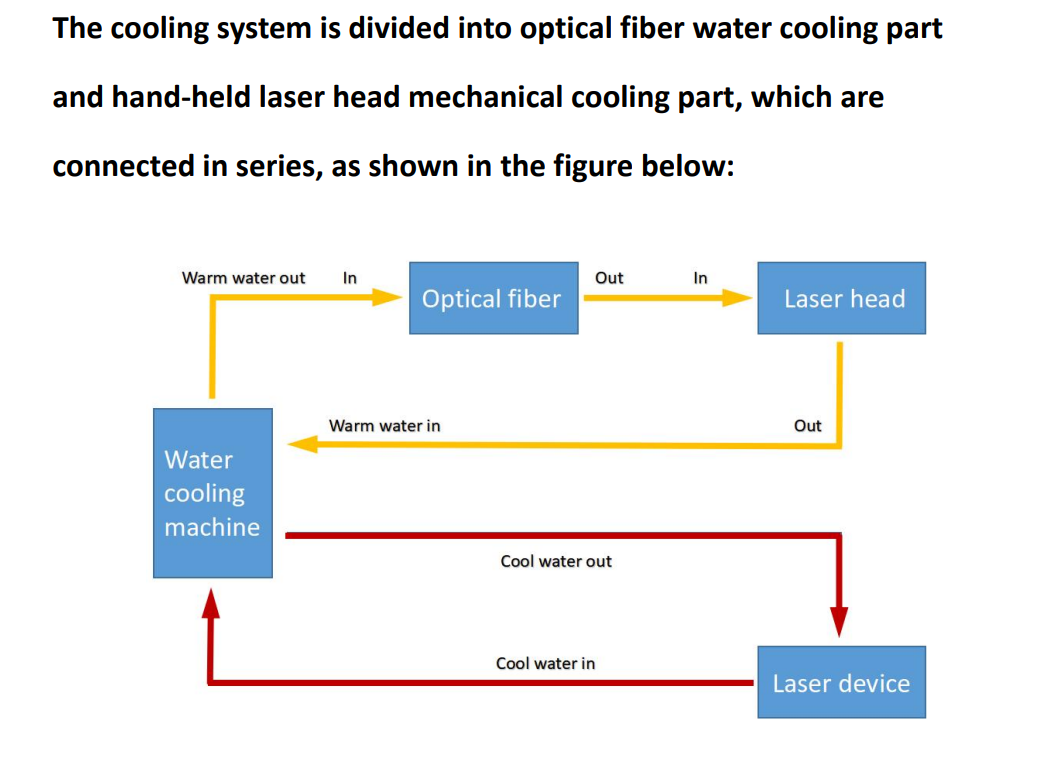

1.Laser and water cooler alarm:

(1) Laser alarm:The water cooler is not on. Shut down the laser and turn it back on.

(2) Water cooler alarm:The water tank temperature is too high, the water cooler compressor is damaged, the refrigerant is missing, or the water cooling mechanism has insufficient cooling power. If Water level of water tank is insufficient alarm, add cooling water.

2. Abnormal screen:

If the screen is off, check whether the four core wires of the control box and the screen are connected properly and whether there are virtual connections.

3.No light emitted:

(1) Whether the laser is started normally.

(2) Whether the screen has a launch permit.

(3) Whether the display screen is running when the light is emitted.

(4) Whether there is any problem with the connection of the laser.

(5) Dirty protective lens: the actual light is weak and not visible.

(6) Whether the optical path is centered.

4. Sudden stop of light output during processing:

Laser alarm (common problems: laser temperature is too high)

What should be paid attention to when purchasing a laser cleaning machine?

1.Generally speaking, the price of a laser cleaning machine is related to its power, the higher the laser power, the more expensive the price. But the purchase of a laser still depends on your specific needs, such as simple cleaning of floating rust, a low-power laser cleaning machine can satisfy, but a high-power laser cleaning machine may cause damage to the workpiece.

2.In order to achieve the best cleaning effect for the corresponding substrate to be cleaned, it is usually necessary to adjust the corresponding parameters such as fiber length, field lens focal depth, output power, pulse width and scanning speed according to the characteristics of different substrates.

3.Laser cleaning machines are divided into handheld laser cleaning machines and large desktop laser cleaning machines. Different laser cleaning machines have different functions and venues. For example, some hand-held laser cleaning machines are only suitable for semiconductor equipment, because the semiconductor environment requires greater environmental protection, and chemical pollutants cannot appear. However, some large ships are different, and the environment is different, and there will be various gaps in the scope of application. Only by choosing targeted and suitable cleaning equipment can we achieve the desired effect.

4.The qualification of the manufacturer of the laser cleaning machine will be related to a series of service issues. As a cleaning machine, the laser cleaning equipment has certain process requirements. The price will vary greatly depending on the process, and the same is true for industrial equipment. Before choosing cleaning equipment, it is recommended to consider the qualifications of laser cleaning equipment manufacturers. It is more appropriate to re-identify their capabilities through follow-up visits to existing cooperative customers.