Fortune Laser Handheld Fiber Laser Welding Machine

Fortune Laser Handheld Fiber Laser Welding Machine

Fortune Laser Handheld Laser Welder Technical Parameters

|

Model |

FL-HW1000 |

FL-HW1500 |

FL-HW2000 |

|

Laser Type |

1070nm Fiber Laser |

||

|

Nominal Laser Power |

1000W |

1500W |

2000W |

|

Cooling System |

Water Cooling |

||

|

Way of working |

Continuous / Modulation | ||

|

Speed range of welder |

0~120 mm/s |

||

|

Focal Spot Diameter |

0.5mm |

||

|

Ambient temperature range |

15~35 ℃ |

||

|

Environmental humidity range |

<70% without condensation | ||

|

Welding thickness |

0.5-1.5mm |

0.5-2mm |

0.5-3mm |

|

Welding gap requirements |

≤1.2mm |

||

|

Operating Voltage |

AC 220V/50HZ 60HZ/ 380V±5V 50HZ 60HZ 60A | ||

|

Cabinet Dimension |

120*60*120cm |

||

|

Wooden Package Dimension |

154*79*137cm |

||

|

Weight |

285KG |

||

|

Fiber length |

Standard 10M, the longest customized length is 15M |

||

|

Application |

Welding and repairing stainless steel, carbon steel, aluminum alloy. |

||

Portable Handheld Laser Welder for Metals

|

Material |

Output power (W) |

Maximum penetration (mm) |

|

Stainless steel |

1000 |

0.5-3 |

|

Stainless steel |

1500 |

0.5-4 |

|

Stainless steel |

2000 |

0.5-5 |

|

Carbon steel |

1000 |

0.5-2.5 |

|

Carbon steel |

1500 |

0.5-3.5 |

|

Carbon steel |

2000 |

0.5-4.5 |

|

Aluminum alloy |

1000 |

0.5-2.5 |

|

Aluminum alloy |

1500 |

0.5-3 |

|

Aluminum alloy |

2000 |

0.5-4 |

|

Galvanized sheet |

1000 |

0.5-1.2 |

|

Galvanized sheet |

1500 |

0.5-1.8 |

|

Galvanized sheet |

2000 |

0.5-2.5 |

Three Colors for Your Options

Advantages of Handheld Laser Welding Machine

1. Wide welding range:

The handheld welding head is equipped with 10M original optical fiber (the longest customized length is 15M), which overcomes the limitations of the workbench space, and can be welded outdoors and long-distance welding;

2. Convenient and flexible to use:

Hand-held laser welding is equipped with movable pulleys, which is comfortable to hold, and can adjust the station at any time, without fixed-point station, free and flexible, and suitable for various working environment scenarios.

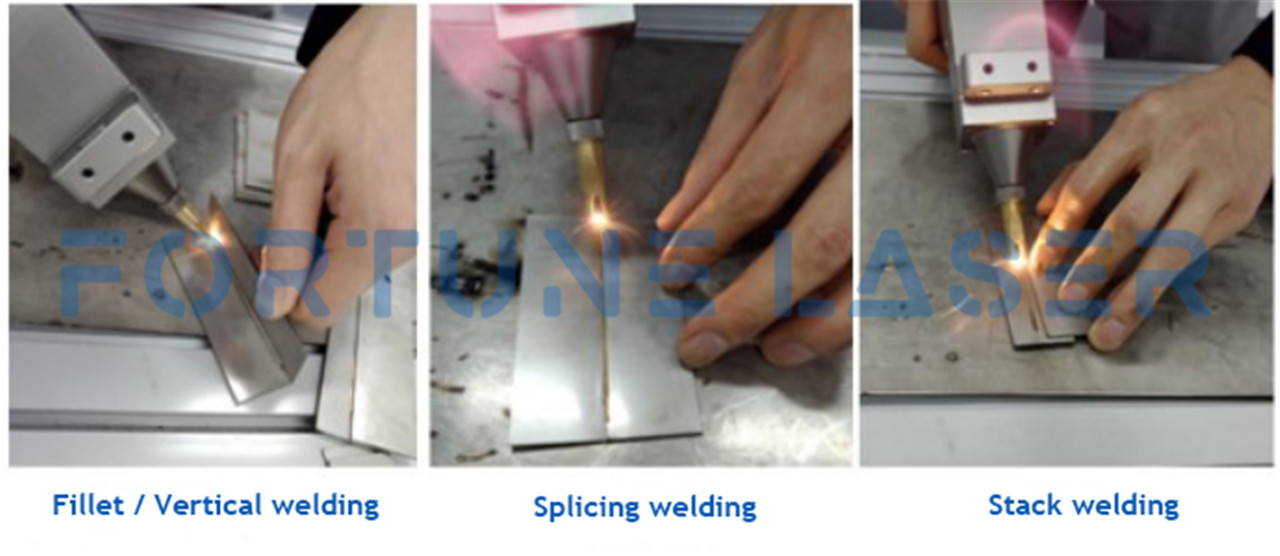

3. Multiple welding methods:

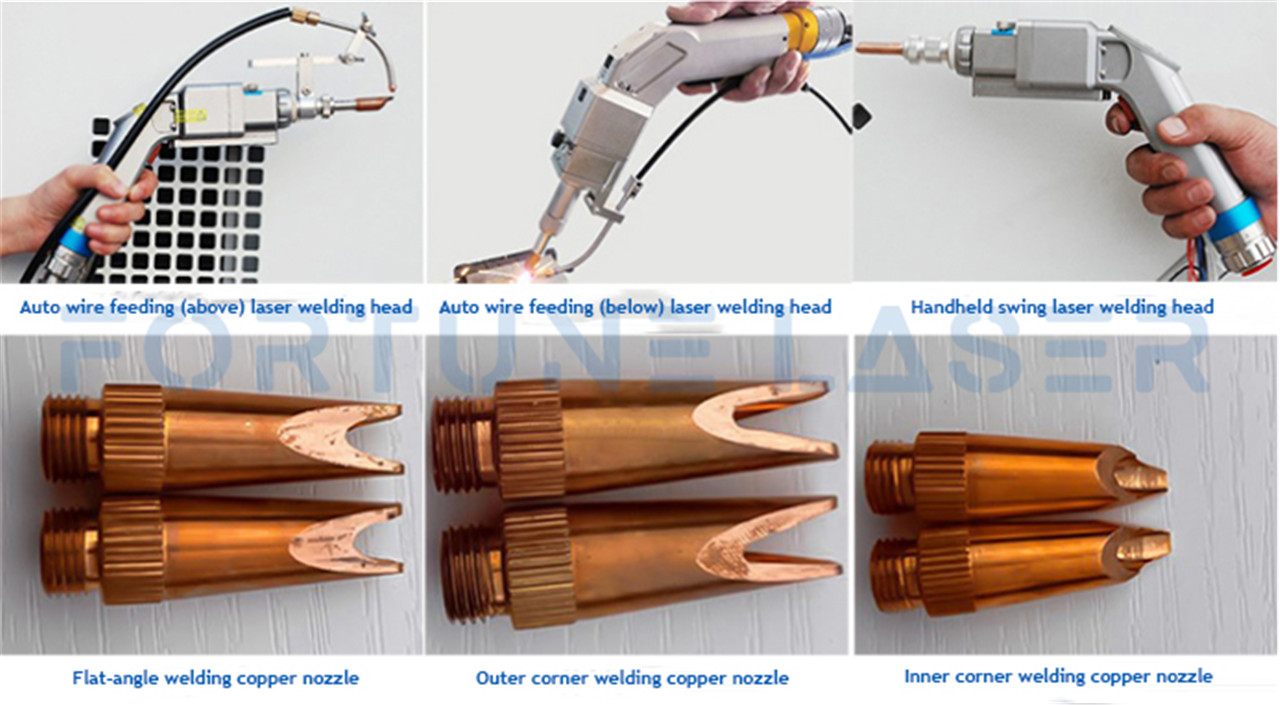

Welding at any angle can be realized: overlap welding, butt welding, vertical welding, flat fillet welding, internal fillet welding, external fillet welding, etc., and can weld various complex welded work-pieces and large work-pieces with irregular shapes. Realize welding at any angle. In addition, it can also complete the cutting, welding and cutting can be switched freely, just change the welding copper nozzle to the cutting copper nozzle, which is very convenient.

4. Good welding effect:

Hand-held laser welding is thermal fusion welding. Compared with traditional welding, laser welding has a higher energy density and can achieve better welding results. The welding area has little thermal influence, is not easy to deform, black, and has traces on the back. The welding depth is large, the melting is sufficient, and it is firm and reliable, and the weld strength reaches or exceeds the base metal itself, which cannot be guaranteed by ordinary welding machines.

5. Welding seam does not need to be polished.

After traditional welding, the welding point needs to be polished to ensure that it is smooth and not rough. The hand-held laser welding precisely reflects more advantages in the processing effect: continuous welding, smooth and no fish scales, beautiful and no scars, and fewer follow-up polishing procedures.

6. Welding with automatic wire feeder.

In most people's impression, the welding operation is "left hand goggles, right hand clamp welding wire". But with the handheld laser welding machine, the welding can be completed easily, which reduces the material cost in production and processing.

7. Safer for operator.

With multiple safety alarms, the welding tip is only effective when the switch is touched when it touches the metal, and the light is automatically locked after the work piece is removed, and the touch switch has body temperature sensing. The safety is high to ensure the safety of the operator during work.

8. Save labor cost.

Compared with arc welding, the processing cost can be reduced by about 30%. The operation is simple, easy to learn, and quick to get started. The technical threshold of operators is not high. Ordinary workers can take up their posts after a short training, which can easily achieve high-quality welding results.

9. Easy to switch from traditional welding methods to fiber laser welding.

You can learn how to use Fortune Laser fiber laser welding machine within a few hours, and no headache to look for welding experts, no worry about the tight delivery schedule. What’s more, with this new technology and investment, you’ll be ahead of the market and embrace increased profit margins than the traditional welding methods.

Application Fields of Handheld Laser Welding Machine

The handheld laser welder is mainly for large and medium-sized sheet metal, cabinets, chassis, aluminum alloy door and window frames, stainless steel wash basins and other large work-pieces, such as inner right angle, outer right angle, flat weld welding, small heat-affected area during welding, small deformation, and welding depth Large, strong welding.

Fortune Laser handheld laser welding machines are widely used in the complicated and irregular welding processes of the kitchen and bathroom industry, home appliance industry, advertising industry, mold industry, stainless steel products industry, stainless steel engineering industry, doors and windows industry, handicraft industry, household goods industry, furniture industry, auto parts industry, etc.

Comparison of Handheld Laser Welding Machine and Argon Arc Welding

1. Energy consumption comparison: Compared with traditional arc welding, the handheld laser welding machine saves about 80% to 90% of electric energy, and the processing cost can be reduced by about 30%.

2. Welding effect comparison: laser hand-held welding can complete dissimilar steel and dissimilar metal welding. The speed is fast, the deformation is small, and the heat-affected zone is small. The weld seam is beautiful, smooth, no/less porosity, and no pollution. The handheld laser welding machine can be used for small open parts and precision welding.

3. Follow-up process comparison: low heat input during laser hand-held welding, small deformation of the workpiece, beautiful welding surface can be obtained, no or only simple treatment (depending on the requirements of the welding surface effect). The handheld laser welding machine can greatly reduce the labor cost of the huge polishing and leveling process.

|

Type |

Argon arc welding |

YAG welding |

Handheld Laser welding |

|

|

Welding quality |

Heat input |

Big |

Small |

Small |

|

|

Workpiece deformation/undercut |

Big |

Small |

Small |

|

|

Weld forming |

Fish-scale pattern |

Fish-scale pattern |

Smooth |

|

|

Subsequent processing |

Polish |

Polish |

None |

|

Use operation |

Welding speed |

Slow |

Middle |

Fast |

|

|

Operation difficulty |

Hard |

Easy |

Easy |

|

Environmental protection and safety |

Environmental pollution |

Big |

Small |

Small |

|

|

Body harm |

Big |

Small |

Small |

|

Welder cost |

Consumables |

Welding rod |

Laser crystal, xenon lamp |

No need |

|

|

Energy consumption |

Small |

Big |

Small |

| Equipment floor area |

Small |

Big |

Small |

|