Fortune Laser Large Format Continuous Wave (CW) Laser Cleaning Machine

Fortune Laser Large Format Continuous Wave (CW) Laser Cleaning Machine

What Is CW Large Format Laser Cleaning Machine?

Laser cleaning machine, also called laser cleaner or laser cleaning system, adopts a high energy density of laser beam to create fine, deep cleaning seams and high cleaning rates. Laser cleaning machines are mainly used to cleaning metals. Those laser cleaners for metals have the ability to cleaning dissimilar materials.

Compared with chemical cleaning, laser cleaning does not need any chemical agents and cleaning fluids. Compared with mechanical cleaning, the laser rust remover has no wear and tear, no consumables,and less damage to the substrate. Wide range of applications (even nuclear pipeline cleaning). The technology of the laser rust remover has been applied internationally in all fields (mold cleaning, fighter coating cleaning).

| Product Name | CW large format laser cleaning machine |

| cleaning range | 800mm-1200mm |

| Laser Power | 1000W 1500W 2000W optional |

| Laser Source | Raycus MAX IPG optional |

| Welding Head | SUP |

| Laser Wavelength | 1070nm |

| Pulse Width | 0.5-15ms |

| Pulse Frequency | ≤100Hz |

| Spot adjusting range | 0.1-3mm |

| Repeating precision | ±0.01mm |

| Cabinet size | Standard/ mini optional |

| Cooling System | Water Cooling |

| Voltage | 220V/3-Phase/50Hz |

Technical Data:

|

Model |

FL-C1000 |

FL-C1500 |

FL-C2000 |

|

Laser source |

Fiber Laser |

Fiber Laser |

Fiber Laser |

|

Laser Power |

1000W |

1500W |

2000W |

|

Fiber cable Length |

10M |

10M |

10M |

|

Wavelength |

1080nm |

1080nm |

1080nm |

|

Frequency |

50-5000 Hz |

50-5000 Hz |

50-5000 Hz |

|

Cleaning Head |

Single Axis |

Single Axis |

Single Axis |

|

Clean speed |

≤60 M²/Hour |

≤60 M²/Hour |

≤70 M²/Hour |

|

Cooling |

Water cooling |

Water cooling |

Water cooling |

|

Dimension |

98*54*69cm |

98*54*69cm |

98*54*69cm |

|

Packing size |

108*58*97cm |

108*58*97cm |

108*58*97cm |

|

Net Weight |

120KGS |

120KGS |

120KGS |

|

Gross Weight |

140KGS |

140KGS |

140KGS |

|

Optional |

Manual |

Manual |

Manual |

|

Temperature |

10-40 ℃ |

10-40 ℃ |

10-40 ℃ |

|

Power |

< 7KW |

< 7KW |

< 7KW |

|

Voltage |

Single Phase 220V, 50/60HZ |

Single Phase 220V, 50/60HZ |

Single Phase 220V, 50/60HZ |

What is the difference between a pulsed laser and a continuous laser?

Fiber laser source

(The laser source is divided into continues laser source and pulsed laser source in operation)

Pulsed laser source:

refers to a pulse pf light emitted by a laser source in a pulsed working mode.in short ,it is like the work of a flashlight.When the switch is closed and then immediately turned off,a “light pulse”is send out.Therefore,the pulses are one by one,but the instantaneous power is very high and the duration is very short.It is necessary to work in pulse mode,such as sending signals and reducing heat generation.The laser pulse can be extremely short and has an excellent effect in the field of laser cleaning machines,it does not damage the substrate of the object.The single pulse energy is high,and the effect of removing paint and rust is good.

Continuous laser source:

The laser source continues to provide energy to produce a laser output for a long time.Thus obtaining continuous laser light.Continuous laser output power is generally relatively low.Starting at 1000w.It is suitable for laser metal rust removal.The main feature is that is burns the surface and cannot whiten the surface of the metal.After cleaning the metal,there is a black oxide coating.In addition,it has a good effect for cleaning non-metallic surfaces.

In conclusion, dust could be removed by both the pulsed fiber laser and CW fiber laser. Using the same average output power, the cleaning efficiency of the pulsed fiber laser is quicker than the efficiency of the CW fiber laser. In the meantime, precise heat control between cleaning and melting produces good cleaning performance, without damaging the substrate.

However, the cost of a CW fiber laser is lower, which compensates for the disadvantage of the cleaning efficiency by increasing the average output power. However, it will cause a heat effect, which will hurt the substrate.

Professional cleaning head designed for high power cleaning

Most of the continuous laser cleaning on the market:

Using a welding head with three functions of cutting, welding and cleaning, it is mainly used for welding, and the cleaning range is less than 20mm. When using more than 1500w power, the lens will burn, greatly reducing the life of the laser and cleaning head. Can withstand long cleaning jobs.

Professional cleaning head solution:

Professional laser cleaning head, providing a cleaning range of 800mm-1200mm, can withstand more than 2000w of laser power. It is especially suitable for cleaning scenarios with a large workload and a large degree of rust and dirt.

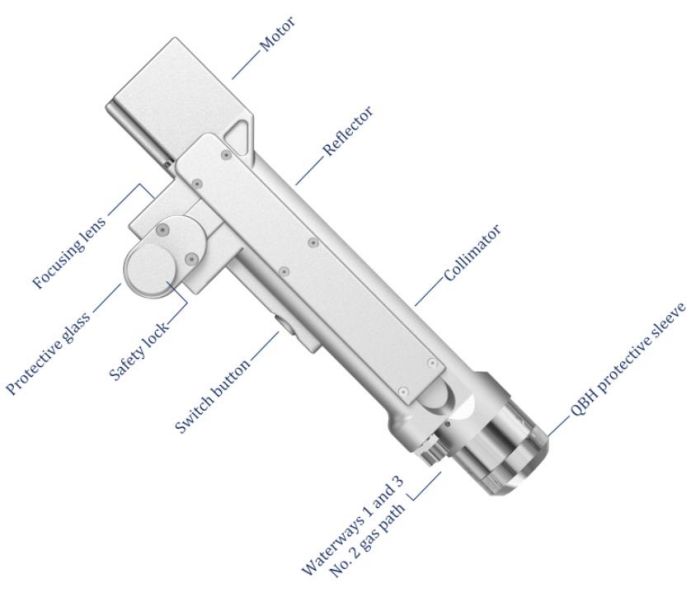

Cleaning head details

| Power supply (V) | 220V ± 10% AC 50/60Hz |

| Placement environment | Flat, vibration and shock free |

| Working Environment (℃) | 10 ~ 40 |

| Working environment humidity (%)<70 | |

| Cooling method | Water chiller cooling |

| Suitable Wavelength | 1064 (±10nm) |

| Suitable laser power | ≤ 2000w |

| Collimating lens | D20*3.5 F50 biconvex lens |

| Focusing lens | D20 F400 plano-convex lens |

| D20 F800 plano-convex lens | |

| Reflector | 20*15.2 T1.6 |

| Protective lens specifications | D20*2 |

| Maximum supported air pressure | 15 bar |

| Focus vertical adjustment range | ± 10mm |

| Spot adjustment range | Line 0~300mm |

| Net Weight | 0.7kg |

Continuous cleaning application

The number of laser cleaning applications is growing exponentially. Every day new possibilities are discovered and explored. From the classical rust removal to the restoration of natural stone building facades. And everything in between: paint removal, de-coating, mold cleaning, de-oiling, special

surface treatment and even labeling and marking. The industrial applications Fortune Laser products are used for vary from the most inaccessible tiny area to vast surfaces of public or private infrastructure. Always delivering results above expectations.

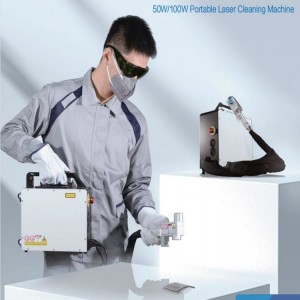

Large-format continuous laser cleaning significantly improves cleaning efficiency, and is especially suitable for cleaning scenarios with heavy workloads. Such as container cleaning, large pipeline cleaning, aircraft aviation material cleaning, ship cleaning, etc.

Professional fiber laser welding cleaning cutting machine manufacturer for metalworking manufacturing industry service business. Laser welder, laser cleaner and laser cutter for sale in Europe, Asia, South America, North America, Africa, Southeast Asia.

The portable laser welders and laser cleaners are more and more popular. Whether you are looking for a cleaning tool for use, or plan to start a laser cleaning service business, this Large format laser cleaning machine is a very good choice. Please contact us today for more details.