Fortune Laser Pulses 200W/300W Handheld Laser Cleaning Machine

Fortune Laser Pulses 200W/300W Handheld Laser Cleaning Machine

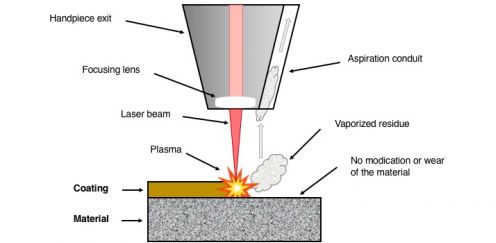

Compared with traditional cleaning, what are the characteristics of laser cleaning?

(1) It is a "dry" cleaning, does not need cleaning liquid or other chemical solutions, and the cleanliness is much higher than the chemical cleaning process;

(2) the range of dirt removal and the applicable base material range is very wide;

(3) By adjusting the laser process parameters, on the basis of not damaging the surface of the substrate, the pollutants can be effectively removed, so that the surface is as old as new;

(4) Laser cleaning can easily realize automatic operation;

(5) Laser decontamination equipment can be used for a long time, low operating cost;

(6) Laser cleaning technology is a "green" cleaning process, the elimination of waste is solid powder, small size, easy to store, basically does not pollute the environment.

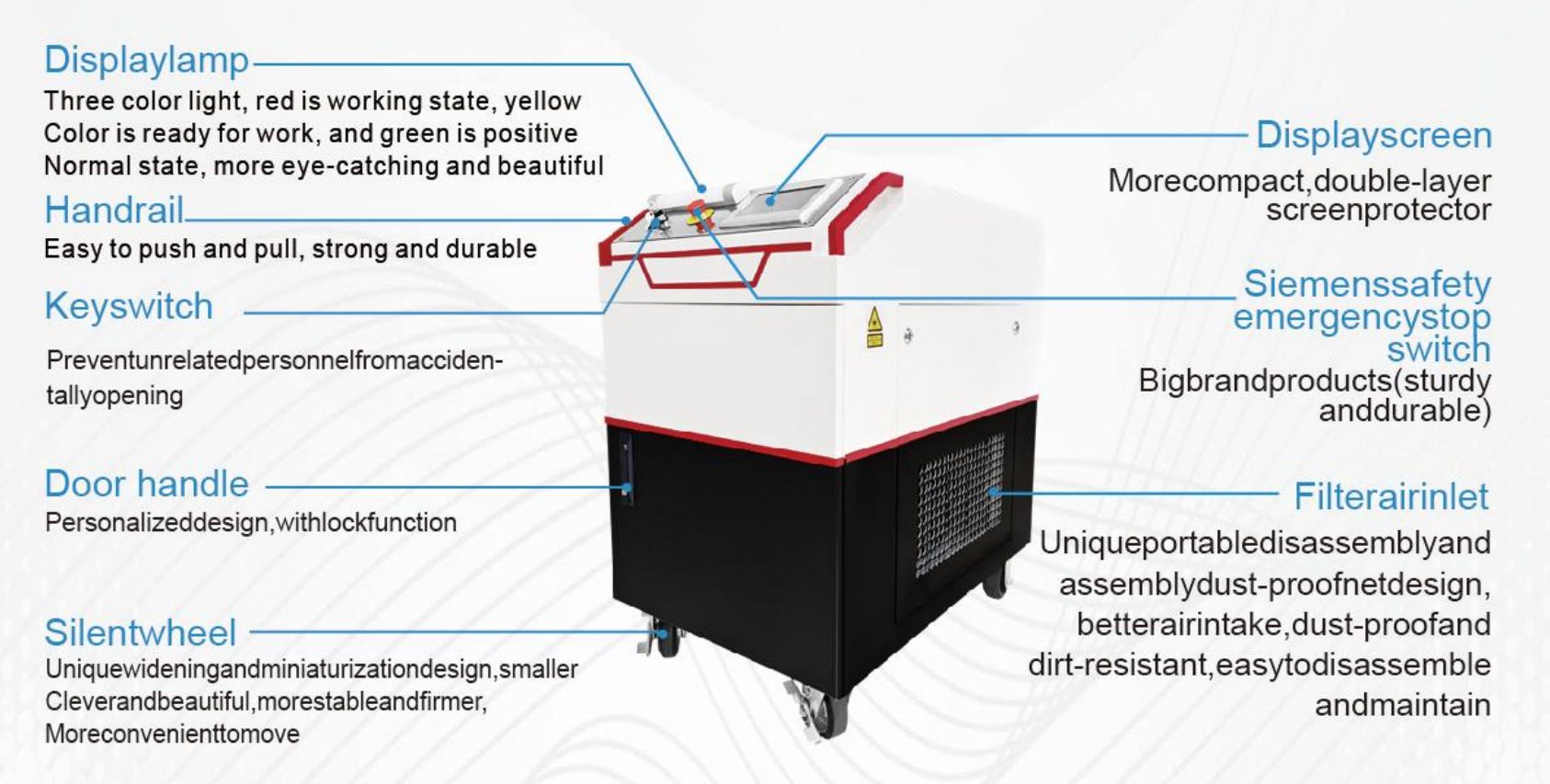

200W 300W Laser Cleaning Machine Features:

● 22-inch trolley case control system: Built-in laser source, laser head and accessories;

● One-touch operation easy operation: advanced user & normal user dual operation interface;

● Dual use laser head: handheld & robotic hold switching time < 5 seconds;

● Focus Lens: 160/254/330/420 for optional suitable for various situations. Can scan straight line, circle, spiral, rectangle, square, round fill, rectangular fill etc. It can add the appropriate scanning pattern according to customer demand;

● Indicator light, safety lock: laser emission indicator, safety lock to;

● laser source connection: suitable for isolator, QCS QBH commonly used laser connectors in the market.

Fortune Laser Mini Laser Welding Machine Technical Parameters

|

Model |

FL-HC200 |

FL-HC300 |

|

|

Laser Type |

Domestic Nanosecond Pulse Fiber |

||

|

Laser Power |

200W |

300W |

|

|

Cooling Way |

Water Cooling |

Water Cooling |

|

|

Laser Wavelength |

1065±5nm |

1065±5nm |

|

|

Power Regulation Range |

10-100% |

||

|

Output Power Instability |

≤5% |

||

|

Output Power Instability |

10-50kHz |

20-50kHz |

|

|

Pulse Length |

90-130ns |

130-140ns |

|

|

Fiber Length |

5 or 10m |

||

|

Maximum Monopulse Energy |

10mJ |

12.5mJ |

|

Main configuration:

● l The fourth generation dual purpose laser head Handheld and automatic, 2D laser head. Easy to hold and integrate with automation; easy to operate and has various functions;

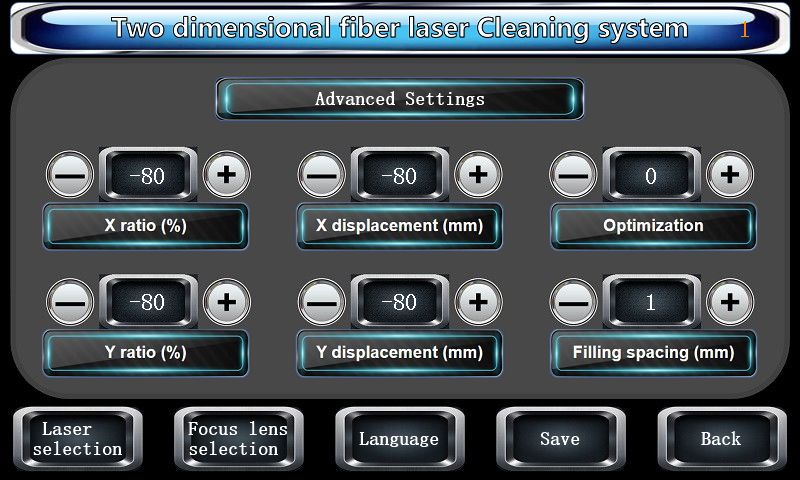

● AIMPLE SOFTWARE

PRESTORE OF VARIOUS PARAMETER GRAPHICS

1. Simple softwareselect prestored parameters directly

2. Prestore all kinds of parameter graphicsix kinds of graphics can beselectedstraightline/spiral/ circle/rectangle/rectanglefilling/Circle filling

3. Easy to use and operate

4. Simpleinterface

5. 12 different modes can be switched and selected

quickly to facilitate production and debug

6. The language can be English/Chinese or other languages(ifrequired)

What does the pulse laser cleaning machine clean?

1. Metal or glass surface coating removal, quick paint removal

2. Rapid rust removal, and various oxides;

3. Remove grease, resin, glue, dust, stains, production residues;

4. Roughened metal surface;

5. Paint stripping, rust removal, oil removal, post-welding oxide and residue treatment before welding or bonding;

6. Mold cleaning, such as tire molds, electronic molds, food molds;

7. Oil stain removal after production and processing of precision parts;

8. Quick cleaning of nuclear power components maintenance;

9. Oxide treatment, paint removal, and rust removal during the

production or maintenance of aerospace weapons and ships;

10. Metal surface cleaning in small spaces.

Matters needing attention when using laser cleaning machine:

1. Regularly clean the laser chiller once every half a month, drain the dirty water in the machine, and refill it with new pure water (dirty water will affect the light output effect);

2. It is required to clean regularly and quantitatively every day, remove the sundries on the table, limiter and guide rail, and spray lubricating oil on the guide rail;

3. The mirror and focusing lens should be scrubbed with special cleaning solution every 6-8 hours. When scrubbing, use a cotton swab or cotton swab dipped in the cleaning solution to scrub from the center of the focusing mirror to the edge in a counterclockwise direction, and be careful to prevent scratches lens;

Video

Laser cleaning machine cleaning effect: