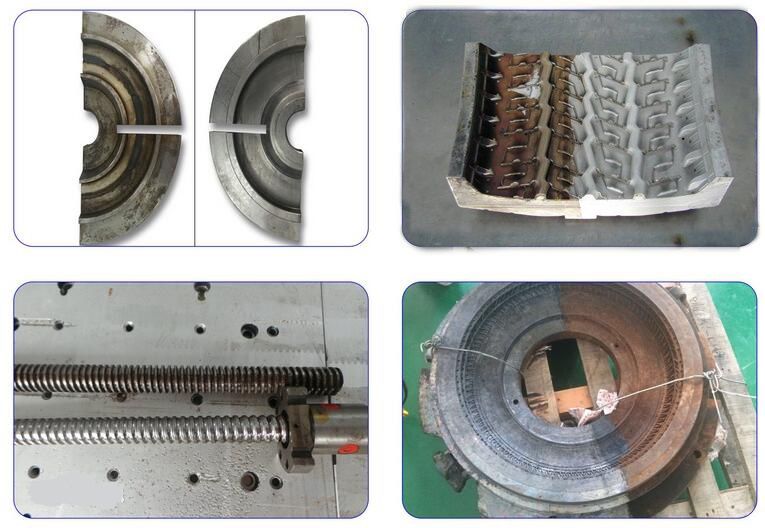

There are millions of mold stocks in various countries. Each industrial product has many styles and requires different molds. Since molds often contact high-temperature raw materials or deal with stamping tensile stress, dirt is easily formed on the surface. If If it is not cleaned in time, it will cause damage to the surface of the mold, and the subsequent products will also appear defective. At present, laser cleaning can effectively clean planes, curved surfaces, holes and gaps. Common hand-held laser cleaning machines can be used to clean the residues on the surface of the mold, and the cleaning time may be only one tenth of the traditional cleaning.

Why can laser be used for cleaning? Why won't it cause damage to the object being cleaned?

First understand the nature of the laser. In simple terms, lasers are no different from the light (visible light and invisible light) that follow us around us, except that lasers use resonators to gather light in the same direction, and have simpler wavelengths, coordination, etc. The performance is better, so theoretically all wavelengths of light can be used to form lasers, but in practice, there are not many media that can be excited, so the laser light source that can generate stable and suitable for industrial production is quite limited.

Speaking of molds, it is easy for many people to understand, from small batches to make cake impressions, to large molds for various industrial products. The carrier and support for the production of large-scale industrial products.

In actual use, the mold also has some problems that need to be solved. The most important problem is the cleaning of mold residues. So far, there is no good solution. Some metal molds are used for the molding of high-temperature hot melt materials, as well as for the die-casting of some metals. After the product is completed and taken out, there are often raw materials left on the mold, which will directly affect the continuous production of the next product, and even need to stop for manual labor. Clean up the mold, resulting in missed time and missed work.

With the progress of the production plan, all kinds of oil stains will accumulate around the mold, which not only damages the service life of the mold, but also greatly affects the qualified rate of finished products. Therefore, it is imperative to remove oil and glue. The cleaning of the mold can better serve the production, and the bright and oil-free workpiece products cannot be without the support of the mold.

Laser cleaning technology is an important link in industrial production and other fields. It subverts traditional mold cleaning technologies such as "chemical cleaning, mechanical grinding, dry ice cleaning, and ultrasonic cleaning". It is a new mold cleaning technology that has developed rapidly in recent years.

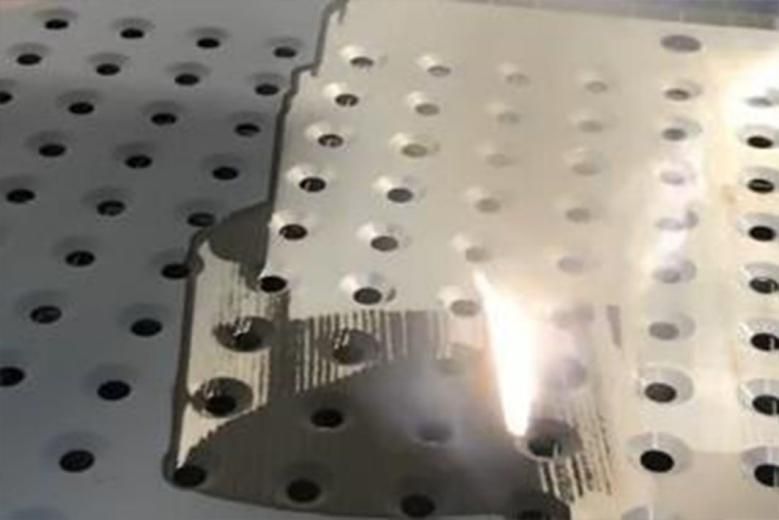

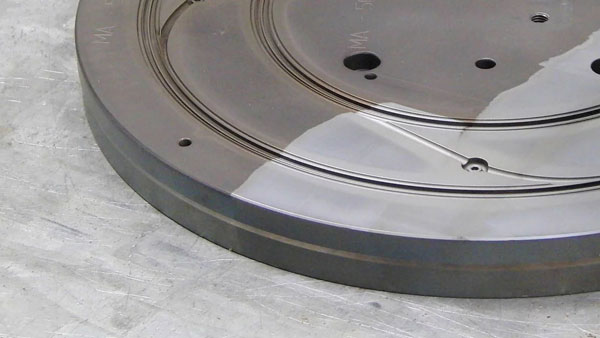

Laser cleaning molds can quickly remove the adhesive layer, oil, etc. on the surface of the mold. For uneven samples, wherever the laser is irradiated, the laser can be cleaned, and the cleaning process can be handled easily. The laser cleaning machine can effectively remove the attachments on various molds such as rubber, silicone, PU, etc. The equipment is easy to operate, does not damage the mold, and the cleaning efficiency can be doubled.

Subdivided from the method, there are 4 types of laser cleaning methods:

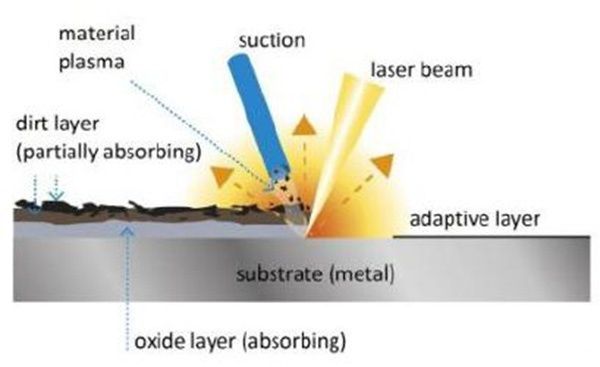

1.Laser dry cleaning method: that is, decontamination by direct radiation of pulsed laser;

2. Laser + liquid film method: that is, first deposit a layer of liquid film on the surface of the substrate, and then decontaminate it with laser radiation; when the laser is irradiated on the liquid film, the liquid film is heated rapidly, resulting in explosive vaporization. Dirt is loose. And fly away from the surface of the processed object with the shock wave to achieve the purpose of decontamination.

3. The method of laser + inert gas: that is, when the laser is irradiated, the inert gas is blown to the surface of the substrate. When the dirt is peeled off from the surface, it will be blown off the surface by the gas immediately to avoid re-contamination and oxidation of the surface;

4. Use the laser to loosen the dirt, and then use the non-corrosive chemical method to clean it. At present, due to the development of high-end manufacturing industry and the continuous improvement of environmental protection requirements, traditional cleaning technologies (chemical methods, mechanical grinding methods) are far from meeting the needs of industrialized production, and the backwardness of cleaning technology restricts the normal production and operation of some important industries.

Therefore, laser cleaning technology, as a representative of green and efficient manufacturing, has a broad market scale under the rapid development of high-end manufacturing.

Laser cleaning molds also has many unique advantages: it can improve the cleanliness; the cleaning cycle is short; the operating cost is low, and the operation is automated; it can reach the designated position quickly and effectively; Replace the traditional cleaning process.

If you want to learn more about laser cleaning, or want to buy the best laser cleaning machine for you, please leave a message on our website and email us directly!

Post time: Nov-10-2022