Laser welding is one of the important aspects of the application of laser processing material processing technology. It is mainly used for welding thin-walled materials and low-speed welding. The welding process belongs to the heat conduction type, that is, the laser radiation heats the surface of the workpiece, and the surface heat diffuses to the inside through heat conduction. By controlling the parameters such as the width, energy, peak power and repetition frequency of the laser pulse, the The workpiece melts to form a specific molten pool. More widely used in machinery manufacturing, aerospace, automobile industry, powder metallurgy, biomedical microelectronics industry and other fields.

With the explosive growth of new energy vehicles, the expansion of power battery production has driven the growth of laser welding. Since the second half of 2018, handheld laser welding has gradually gained popularity, and has become a bright spot in the laser welding market in the first half of this year. With the current technical level and application scenarios of handheld laser welding, it is very likely to replace the traditional TIG welding machine (argon arc welding) market.

In recent years, fiber lasers have made great progress, and their advantages mainly include: high photoelectric conversion rate, fast heat dissipation, good flexibility, strong anti-interference ability, low cost, long life, adjustment-free, maintenance-free, high stability, small size, Hand-held laser welding equipment using fiber lasers has also gradually developed.

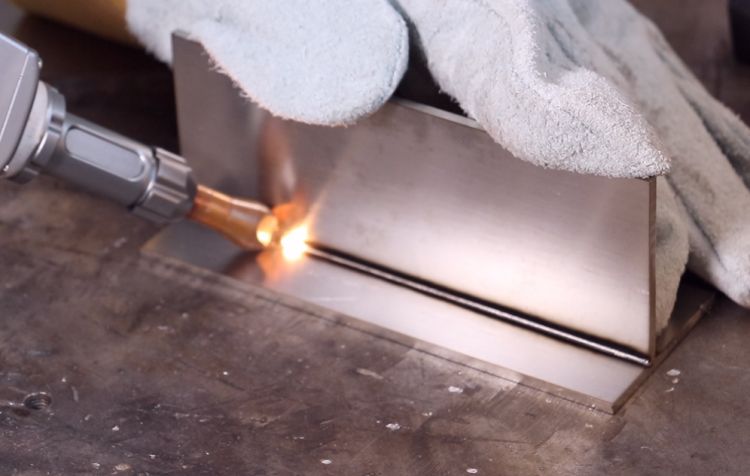

Laser welding requires high assembly precision of the workpiece, and the weld seam is prone to defects. To solve this problem, the designer refers to the laser welding equipment of the special plane to develop a handheld laser welding equipment with a swinging spot. The laser is in the shape of "8" or " 0” type swing can reduce the assembly accuracy of the workpiece and increase the welding penetration. After a series of optimization and improvement, the current common handheld laser welding equipment has a power of 0.5-1.5KW, and the size and weight of the equipment are equivalent to argon arc welding machines, which can weld metal plates of 3mm or less. In order to solve the shortcomings of insufficient weld strength of laser welding structures, in recent years, equipment manufacturers have integrated automatic wire feeding devices on the basis of laser welding, and developed hand-held laser wire-filling welding equipment that can automatically feed wires, which basically meets the needs of thin metal plates below 4m. The welding can basically replace and surpass argon arc welding, realize high speed, low heat input, small deformation, low-cost environmental protection welding, and the manufacturing cost is lower than that of argon arc welding under the same conditions.

When working, the hand-held head of the welding machine has a scanning width, and its spot diameter is small, so when welding, it scans from one point to another point line by line, thus forming a weld bead. Compared with the traditional cold welding machine, the welding speed of the hand-held laser welding will be faster, and the one-shot welding process determines that it is more suitable for mass welding of long straight seams.

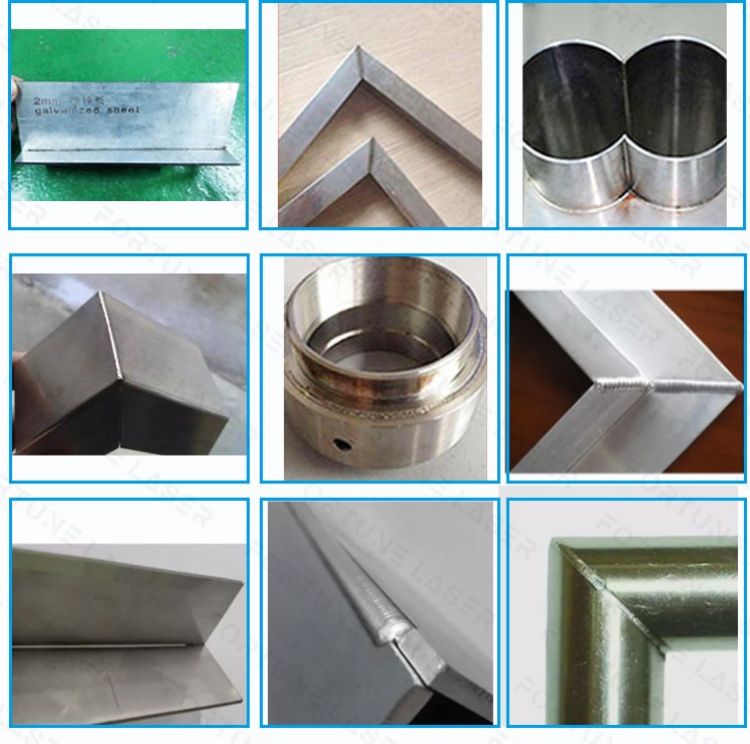

And the hand-held laser welding machine takes up little space, and is usually equipped with a variety of hand-held heads. According to different needs of metal parts such as external welding, internal welding, right-angle welding, narrow edge welding, and large spot welding, different hand-held welding heads can be selected. The products that can be welded are diversified, and the product shape is more flexible. For production workshops engaged in small-scale processing and non-large-scale welding, handheld laser welding machines are definitely the best choice.

Different metal materials have different melting points: the setting of welding parameters for different types of welding materials is relatively complicated, and the thermophysical properties of welding materials will show different differences with temperature changes; the absorption rate of different types of materials for laser will also vary with The temperature changes show different differences; the solder joint melting and the structural evolution of the heat-affected area during the solidification of the weldment; the joint defects of the hand-held laser welding machine, welding participation stress and thermal deformation, etc. But the most important one is the influence of the difference in the properties of the welding materials on the macro and micro properties of the weld.

What materials can hand-held laser welding machine weld?

1. Stainless steel

Stainless steel has a high coefficient of thermal expansion, and it is prone to overheating during welding. When the heat-affected zone is a little large, it will cause serious deformation problems. However, the heat generated by the handheld laser welding machine during the entire welding process is low. Coupled with the relatively low thermal conductivity, high energy absorption rate and melting efficiency of stainless steel, well-formed, smooth and beautiful welds can be obtained after welding.

2. Carbon steel

Ordinary carbon steel can be welded directly by hand-held laser welding, the effect is comparable to stainless steel welding, and the heat-affected zone is smaller, but when welding medium and high carbon steel, the residual temperature is relatively high, so it is still necessary to weld before welding. Preheating and heat preservation after welding to relieve stress and avoid cracks. Here we can talk about the cold welding machine. Medium and high carbon steel can be welded or repaired at a slow speed with cold welding and cast iron welding wire. In terms of temperature control, temperature control, and temperature control, the cold welding machine can teach hand-held laser welding more efficient on the heat residue after welding.

3. Die steel

It is suitable for welding various types of die steel, and the welding effect is very good.

4. Aluminum and aluminum alloy

Aluminum and aluminum alloys are highly reflective materials, and porosity may appear in the molten pool or at the root during welding. Compared with the previous metal materials, aluminum and aluminum alloys have higher requirements for parameters, but as long as the selected welding parameters are appropriate , the weld seam with the same mechanical properties as the base metal can be obtained.

5. Copper and copper alloy

The thermal conductivity of copper is very strong, and it is easy to cause incomplete penetration and partial fusion during welding. Usually, the copper material is heated during the welding process to assist welding. Here we are talking about thin copper materials. Hand-held laser welding can directly Welding, because of its concentrated energy and fast welding speed, is less affected by the high thermal conductivity of copper.

6. Welding between dissimilar materials

The hand-held laser welding machine can be carried out between a variety of dissimilar metals, such as copper-nickel, nickel-titanium, copper-titanium, titanium-molybdenum, brass-copper, low carbon steel-copper and other dissimilar metals. Laser welding can be carried out under any conditions (gas or temperature).

Handheld laser welding machine is currently a widely used product in the welding industry, mainly because although this equipment looks more expensive, it can save labor costs very well. The labor cost of welders is relatively expensive. Using this The product solves the problem of expensive and difficult recruitment of welders. Moreover, the handheld laser welding machine has won unanimous praise from thousands of customers due to its long service life and low energy consumption.

If you want to learn more about laser cleaning, or want to buy the best laser cleaning machine for you, please leave a message on our website and email us directly!

Post time: Dec-03-2022