I-laser weldingingenye yezici ezibalulekile zokusetshenziswa kobuchwepheshe bokucubungula izinto ezibonakalayo nge-laser.Isetshenziswa kakhulu ukushisela izinto ezinodonga oluncane kanye nokushisela okunejubane eliphansi.Inqubo yokushisela ingeyohlobo lwe-heat conduction, okungukuthi, imisebe ye-laser ishisa ingaphezulu le-workpiece, futhi ukushisa okungaphezulu kusakazekela ngaphakathi ngokuqhutshwa kokushisa.Ngokulawula amapharamitha afana nobubanzi, amandla, amandla aphezulu kanye nemvamisa yokuphindaphinda kwe-laser pulse, i-Workpiece iyancibilika ukuze yakhe ichibi elithile elincibilikisiwe.Isetshenziswa kabanzi ekwenziweni kwemishini, i-aerospace, imboni yezimoto, i-powder metallurgy, imboni ye-biomedical microelectronics neminye imikhakha.

Ngokukhula okukhulu kwezimoto zamandla amasha, ukwanda kokukhiqizwa kwebhethri yamandla kuqhubekisele ukukhula kwe-laser welding.Kusukela engxenyeni yesibili ka-2018, i-laser welding ephathwa ngesandla ithole ukuthandwa kancane kancane, futhi isiphenduke indawo ekhanyayo emakethe yokushisela i-laser engxenyeni yokuqala yalo nyaka.Ngezinga lamanje lobuchwepheshe kanye nezimo zohlelo lokusebenza zewelding laser welding, kungenzeka kakhulu ukuthi kuthathelwe indawo umshini wokushisela we-TIG wendabuko (i-argon arc welding) imakethe.

Eminyakeni yakamuva,i-fiber lasersbenze inqubekelaphambili enkulu, futhi izinzuzo zabo ikakhulukazi zihlanganisa: izinga eliphezulu lokuguqulwa kwesithombe sikagesi, ukuchithwa kokushisa okusheshayo, ukuguquguquka okuhle, ikhono eliqinile lokulwa nokuphazamiseka, izindleko eziphansi, impilo ende, ukungalungiswa, ukungalondolozi, ukuzinza okuphezulu, usayizi omncane, Isandla -imishini yokushisela i-laser esebenzisa i-fiber lasers nayo ithuthuke kancane kancane.

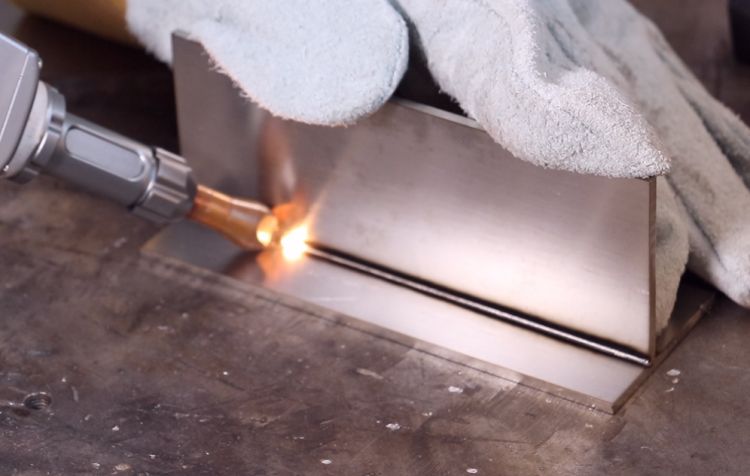

I-laser weldingidinga ukunemba okuphezulu komhlangano we-workpiece, futhi umthungo we-weld uthambekele ekubeni namaphutha.Ukuxazulula le nkinga, umklami ubhekisela kumishini yokushisela nge-laser yendiza ekhethekile ukuze kuthuthukiswe umshini wokushisela we-laser ophathwa ngesandla onendawo eshwibayo.I-laser isesimweni sokushwibeka kohlobo lwe-"8" noma "0" inganciphisa ukunemba komhlangano we-workpiece futhi yandise ukungena kokushisela. Ngemva kochungechunge lokuthuthukisa nokwenza ngcono, umshini wokushisela we-laser ovamile ophathwa ngesandla unamandla angu-0.5 -1.5KW, nosayizi nesisindo semishini ilingana nemishini yokushisela ye-argon arc, engashisela amapuleti ensimbi angu-3mm noma ngaphansi. abakhiqizi bahlanganise amadivaysi okuphakela ngocingo okuzenzakalelayo ngesisekelo se-laser welding, futhi bathuthukise imishini yokushisela ephathwa ngesandla ye-laser wire-filling engakwazi ukondla izintambo ngokuzenzakalelayo, ehlangabezana ngokuyisisekelo nezidingo zamapuleti ensimbi amancane angaphansi kuka-4m. i-argon arc welding, qaphela isivinini esikhulu, okokufaka okuphansi kokushisa, ukuwohloka okuncane, ukushisela ukuvikelwa kwemvelo okungabizi kakhulu, futhi izindleko zokukhiqiza ziphansi kunalezo ze-argon arc welding u.ngaphansi kwezimo ezifanayo.

Lapho isebenza, ikhanda elibanjwe ngesandla lomshini wokushisela linobubanzi bokuskena, futhi ububanzi bendawo yalo buncane, ngakho lapho lishisela, liskena lisuka kwelinye iphuzu liye kwelinye iphuzu umugqa ngomugqa, ngaleyo ndlela lenze ubuhlalu bokushisela.Uma kuqhathaniswa nomshini wokushisela obandayo wendabuko, ijubane lokushisela le-laser welding elibanjwe ngesandla lizoshesha, futhi inqubo ye-welding eyodwa-shot inquma ukuthi ifaneleka kakhulu ukushiswa kwe-mass of seams ende eqondile.

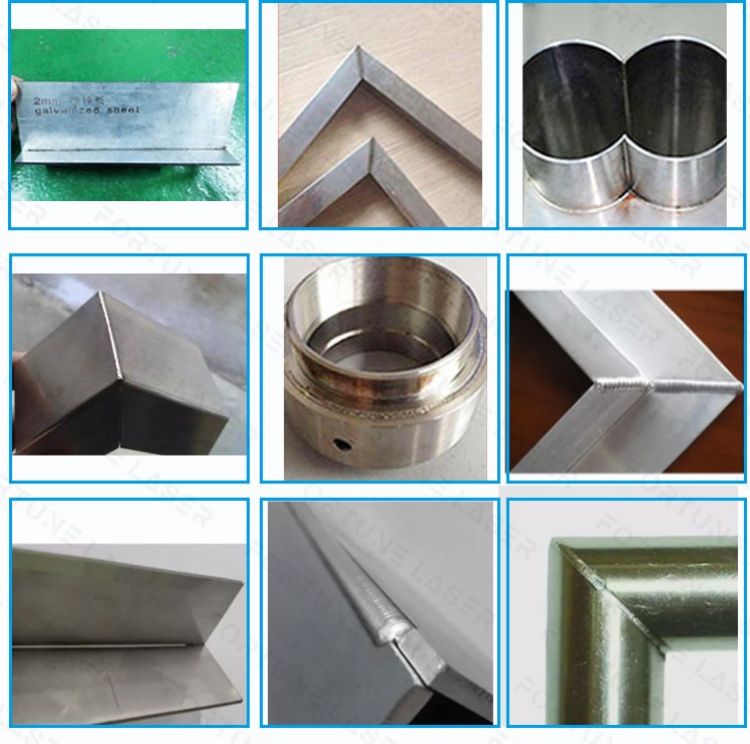

Futhi umshini wokushisela we-laser ophethwe ngesandla uthatha indawo encane, futhi ngokuvamile ufakwe amakhanda ahlukahlukene aphethwe ngesandla.Ngokwezidingo ezahlukene zezingxenye zensimbi ezifana ne-welding yangaphandle, i-welding yangaphakathi, i-right-angle welding, i-welding enqenqemeni ewumngcingo, kanye ne-spot welding enkulu, amakhanda ahlukene aphethwe ngesandla angakhethwa.Imikhiqizo ekwazi ukushiselwa ihlukene, futhi umumo womkhiqizo uvumelana nezimo.Kuma-workshops okukhiqiza asebenza ekucubunguleni okuncane kanye nokushisela okungeyona okukhulu, imishini yokushisela i-laser ephathwayo iyisinqumo esingcono kakhulu.

Izinto ezihlukahlukene zensimbi zinezindawo ezihlukahlukene zokuncibilika: ukumiswa kwemingcele ye-welding yezinhlobo ezahlukene zezinto zokuthungatha kuyinkimbinkimbi, futhi izakhiwo ze-thermophysical ze-welding materials zizobonisa umehluko ohlukile ngokushintsha kwezinga lokushisa;izinga lokumuncwa lezinhlobo ezahlukene zezinto ze-laser nalo lizohluka ngokwezinguquko zokushisa zibonisa umehluko ohlukile;ukuncibilika okuhlangene kwe-solder kanye nokuvela kwesakhiwo sendawo ethintekile ekushiseni ngesikhathi sokuqiniswa kwe-weldment;amaphutha ahlangene omshini wokushisela we-laser ophethwe ngesandla, ukucindezeleka kokubamba iqhaza kwe-welding kanye ne-thermal deformation, njll. Kodwa okubaluleke kakhulu ithonya lomehluko wezakhiwo zezinto zokuthungatha ku-macro kanye nezakhiwo ezincane ze-weld.

Yiziphi izinto ezingakwaziumshini wokushisela we-laser ophethwe ngesandlaweld?

1. Insimbi engagqwali

Insimbi engagqwali ine-coefficient ephezulu yokwanda okushisayo, futhi ijwayele ukushisa ngokweqile ngesikhathi sokushisela.Lapho indawo ethinteke ekushiseni inkulu kancane, izodala izinkinga ezinkulu zokuguga.Nokho, ukushisa okukhiqizwa umshini wokushisela we-laser ophethwe ngesandla phakathi nayo yonke inqubo yokushisela kuphansi.Ngokuhambisana ne-thermal conductivity ephansi, izinga eliphezulu lokumunca amandla kanye nokusebenza kahle kokuncibilika kwensimbi engagqwali, ama-welds akhiwe kahle, abushelelezi futhi amahle angatholakala ngemva kokushisela.

2. Insimbi yekhabhoni

I-carbon steel evamile ingashiselwa ngokuqondile nge-laser welding ephathwa ngesandla, umphumela uqhathaniswa nokushisela insimbi engagqwali, futhi indawo ethinteke ukushisa incane, kodwa uma i-welding medium ne-high carbon steel ishisa, izinga lokushisa elisele liphakeme kakhulu, ngakho-ke kusadingeka ukushisela ngaphambi kokushisela.Ukushisa nokugcinwa kokushisa ngemuva kokushisela ukuze kunciphise ukucindezeleka nokugwema imifantu.Lapha singakhuluma ngomshini wokushisela obandayo.Insimbi ye-carbon emaphakathi nephezulu ingashiselwa noma ilungiswe ngesivinini esincane ngokushisela okubandayo nocingo lokushisela lwensimbi.Mayelana nokulawula izinga lokushisa, ukulawulwa kwezinga lokushisa, nokulawula izinga lokushisa, umshini wokushisela obandayo ungafundisa i-laser welding ebanjwa ngesandla ngokuphumelelayo endaweni esele yokushisa ngemva kokushisela.

3. Die steel

Ifanele ukushisela izinhlobo ezahlukene zensimbi yokufa, futhi umphumela wokushisela muhle kakhulu.

4. I-Aluminium ne-aluminium ingxubevange

I-Aluminium ne-aluminium alloys yizinto ezibonisa ukukhanya kakhulu, futhi i-porosity ingase ivele echibini elincibilikisiwe noma empandeni ngesikhathi sokushisela.Uma kuqhathaniswa nezinto zangaphambilini zensimbi, i-aluminium ne-aluminium alloys inezidingo eziphakeme zemingcele, kodwa uma nje imingcele ye-welding ekhethiwe ifanelekile, i-weld seam enezici ezifanayo zemishini njengoba isisekelo sensimbi singatholakala.

5. Ingxube yethusi neyethusi

I-thermal conductivity yethusi inamandla kakhulu, futhi kulula ukubangela ukungena okungaphelele kanye nokuhlanganiswa okuyingxenye ngesikhathi sokushisela.Imvamisa, izinto zethusi ziyashiswa ngesikhathi senqubo yokushisela ukusiza ukushisela.Lapha sikhuluma ngezinto zethusi ezincane.I-laser welding ephathwa ngesandla ingakwazi ukushisela i-Welding, ngenxa yamandla ayo agxilile kanye nesivinini sokushisela okusheshayo, ayithinteki kakhulu yi-high conductivity eshisayo yethusi.

6. Ukushisela phakathi kwezinto ezingafani

Umshini wokushisela we-laser ophethwe ngesandla ungenziwa phakathi kwezinhlobonhlobo zezinsimbi ezingafani, njengethusi-nickel, i-nickel-titanium, i-copper-titanium, i-titanium-molybdenum, ithusi-ithusi, i-carbon steel-copper ephansi nezinye izinsimbi ezingafani.I-laser welding ingenziwa ngaphansi kwanoma yiziphi izimo (igesi noma izinga lokushisa).

Umshini wokushisela we-laser ophathwa ngesandla njengamanje ungumkhiqizo osetshenziswa kabanzi embonini yokushisela, ikakhulukazi ngoba nakuba le mishini ibonakala ibiza kakhulu, ingasindisa izindleko zabasebenzi kahle kakhulu.Izindleko zomsebenzi zabashiseli zibiza kakhulu.Ukusebenzisa lokhu Umkhiqizo uxazulula inkinga yokuqashwa okumba eqolo futhi okunzima kwama-welders.Ngaphezu kwalokho, umshini wokushisela we-laser ophethwe ngesandla uzuze ukunconywa ngazwi linye ezinkulungwaneni zamakhasimende ngenxa yempilo ende yesevisi kanye nokusetshenziswa kwamandla okuphansi.

Uma ufuna ukufunda okwengeziwe mayelana nokuhlanza i-laser, noma ufuna ukukuthengela umshini wokuhlanza we-laser ongcono kakhulu, sicela ushiye umlayezo kuwebhusayithi yethu futhi usithumele i-imeyili ngokuqondile!

Isikhathi sokuthumela: Dec-03-2022