Gold and silver jewelry is indispensable in people's life, but no matter how expensive it is, it also needs people's meticulous processing to show its proper color. However, there is a relatively cumbersome matter in jewelry processing, that is, laser welding. Be very careful when soldering, and also require extremely good eyesight.

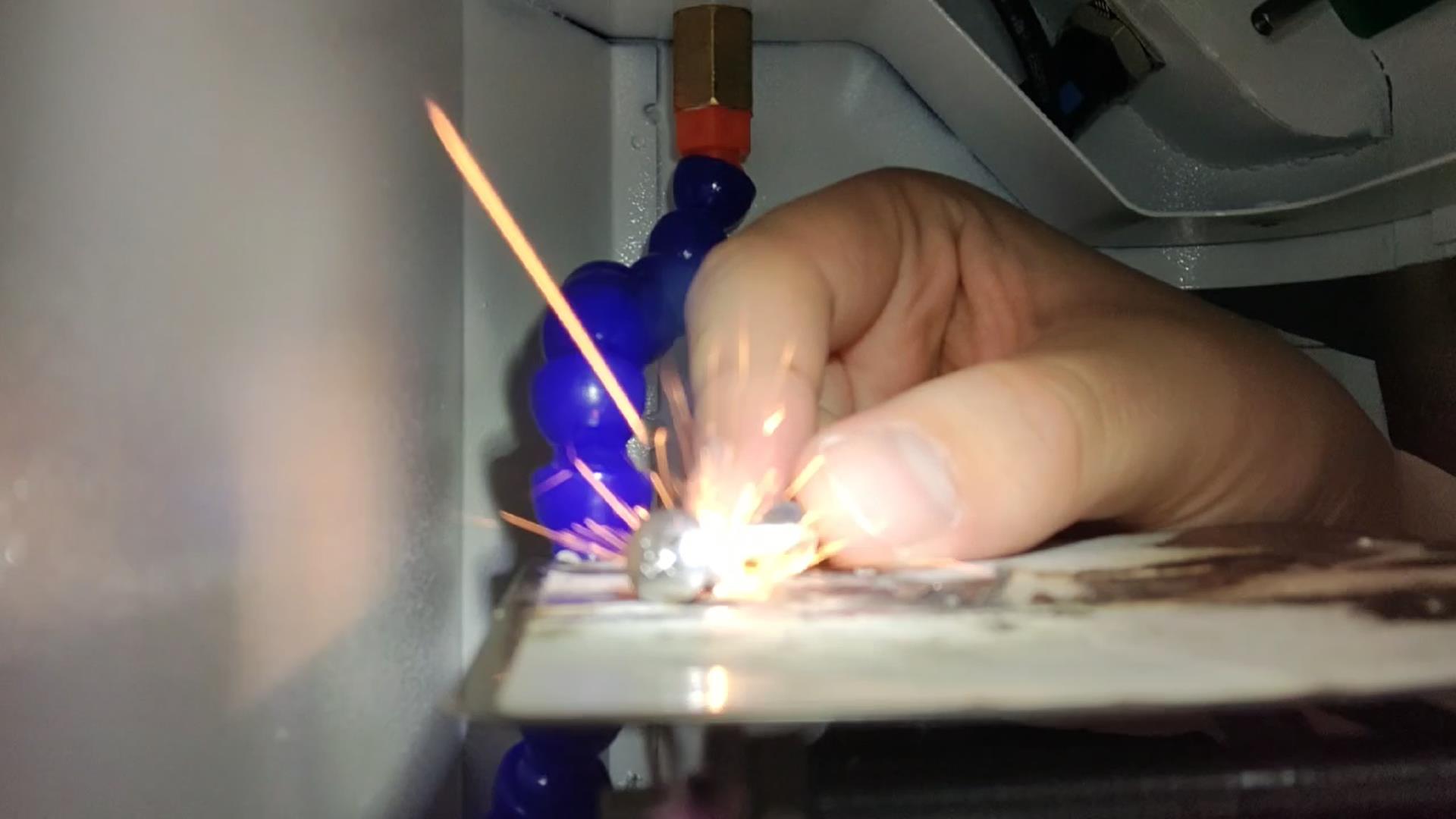

Jewelry laser spot welding machine is mainly used for repairing holes and spot welding blisters of gold and silver jewelry. Laser spot welding is one of the important aspects of the application of laser material processing technology. The heat diffuses into the interior through thermal conduction, and by controlling parameters such as the width, energy, peak power and repetition frequency of the laser pulse, the workpiece is melted to form a specific molten pool. Due to its unique advantages, it has been successfully used in gold and silver jewelry processing and welding of micro and small parts.

The laser spot welding machine is mainly composed of laser, power supply and control, cooling machine, light guide and focusing, and binocular stereomicroscopic observation. It has a compact structure and small volume. Laser power, pulse frequency and pulse width can be preset and changed through the control panel. The power supply adopts a drawer structure, which is easy to remove, so the equipment is easy to operate and maintain. No need to fill solder, high welding speed, reliable contact, small deformation of workpiece, beautiful forming.

Jewelry laser spot welding machine features:

●Energy, pulse width, frequency, spot size, etc. can be adjusted in a wide range to achieve various welding effects. Parameters are adjusted by levers in the closed chamber, simple and efficient.

●Using the ceramic concentrator cavity imported from the UK, which is resistant to corrosion, high temperature, and high photoelectric conversion efficiency.

●Using the world's most advanced automatic shading system to eliminate eye irritation during working hours.

●With 24-hour continuous working ability, the whole machine has stable working performance and is maintenance-free within 10,000 hours.

●Humanized design, in line with ergonomics, long time working without fatigue.

As gold and silver jewelry on the market is getting thinner and more delicate, problems such as breaking and breaking often occur during the production or wearing process. The repair of jewelry often requires laser welding technology. Jewelry laser welding machines have played an important role in the market of this industry. Because of the many delicate metal jewelry, many processes are completed by the high-end technology of laser welding.

So why do jewelry use laser welding machines? How is it different from traditional crafts?

The traditional jewelry production process is to melt the metal at high temperature, then weld and process it. This welding process often causes burning black in the jewelry, which cannot be completely removed even after later cleaning, and sometimes causes the original jewelry itself. The gloss decreases, which seriously affects the aesthetics of the jewelry. For the problems encountered in the processing of jewelry or repairing laser welding, the jewelry laser welding machine can easily and quickly solve the problem. It is to adjust the light spot at the welding place of jewelry such as gold and silver, enlarge the welding area through the observation hole, and carry out the processing on the position to be processed spot welding.

What are the advantages of applying laser spot welding technology in jewelry processing and repairing?

Basically, laser spot welding is a type of thermal conductivity, which has a small thermal influence on jewelry, small solder joints, and will not contaminate other parts.This advantage is also widely used in the welding of precision precision parts. In addition, this technology will also cooperate with the system control to improve the stable working performance of the machine and equipment. It can control the frequency and intensity of the light to ensure the welding effect of complex structures or details, enhance the precision of the welding work, and avoid the traditional welding on the human body. eye damage.

If you want to learn more about laser welding machine, or want to buy the best laser welding machine for you, please leave a message on our website and email us directly!

Post time: Nov-26-2022