Zodzikongoletsera za golide ndi siliva ndizofunikira kwambiri pamoyo wa anthu, koma ngakhale zitakwera bwanji, zimafunikiranso kukonzedwa bwino ndi anthu kuti ziwonetse mtundu wake woyenera.Komabe, pali nkhani yovuta kwambiri pakukonza zodzikongoletsera, ndiko kuti,laser kuwotcherera.Samalani kwambiri mukamagulitsa, komanso pamafunika maso abwino kwambiri.

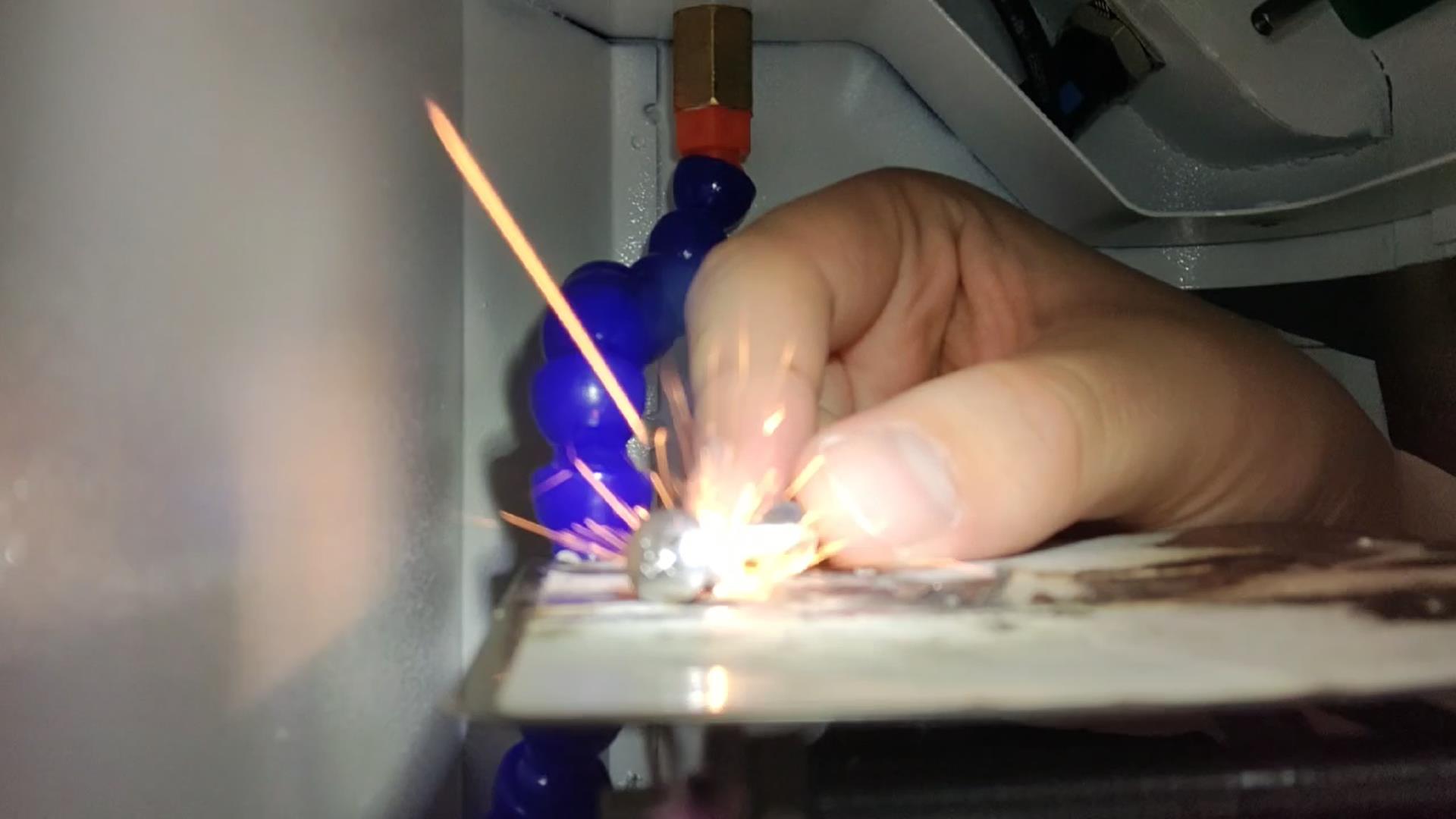

Zodzikongoletsera laser malo kuwotcherera makinaamagwiritsidwa ntchito makamaka pokonza maenje ndi kuwotcherera matuza agolide ndi zodzikongoletsera zasiliva.Kuwotcherera kwa laser ndi chimodzi mwazinthu zofunika kwambiri pakugwiritsa ntchito luso laukadaulo la laser.Kutentha kumafalikira mkati mwa matenthedwe matenthedwe, ndipo poyang'anira magawo monga m'lifupi, mphamvu, mphamvu yapamwamba ndi kubwerezabwereza kwa laser pulse, workpiece imasungunuka kuti ipange dziwe losungunuka.Chifukwa cha ubwino wake wapadera, wakhala bwino ntchito golide ndi siliva zodzikongoletsera processing ndi kuwotcherera ya yaying'ono ndi yaing'ono mbali.

Makina owotcherera a laser spotmakamaka amapangidwa ndi laser, magetsi ndi kuwongolera, makina ozizira, kalozera wopepuka ndi kuyang'ana, ndi kuyang'ana kwa ma binocular stereomicroscopic.Ili ndi mawonekedwe ophatikizika komanso voliyumu yaying'ono.Mphamvu ya laser, kugunda kwafupipafupi ndi kugunda kwapakati kumatha kukhazikitsidwa ndikusinthidwa kudzera pagawo lowongolera.Mphamvu zamagetsi zimagwiritsa ntchito kabati, zomwe zimakhala zosavuta kuzichotsa, kotero kuti zipangizozo ndizosavuta kugwiritsa ntchito ndi kusamalira.Palibe chifukwa chodzaza solder, liwiro lowotcherera kwambiri, kukhudzana kodalirika, mapindikidwe ang'onoang'ono a workpiece, mawonekedwe okongola.

Zodzikongoletsera laser malo kuwotcherera makina mbali:

● Mphamvu, zimachitika m'lifupi, pafupipafupi, malo kukula, etc. akhoza kusinthidwa osiyanasiyana kukwaniritsa zosiyanasiyana kuwotcherera zotsatira.Ma parameters amasinthidwa ndi ma levers mu chipinda chotsekedwa, chosavuta komanso chothandiza.

● Kugwiritsa ntchito makina a ceramic concentrator omwe amatumizidwa kuchokera ku UK, omwe sagonjetsedwa ndi dzimbiri, kutentha kwambiri, komanso kusinthasintha kwakukulu kwa photoelectric.

● Kugwiritsa ntchito makina apamwamba kwambiri a shading padziko lonse lapansi kuti athetse vuto la maso pa nthawi ya ntchito.

● Pokhala ndi mphamvu yogwira ntchito mosalekeza kwa maola 24, makina onse ali ndi ntchito yokhazikika yogwira ntchito ndipo sakonza mkati mwa maola 10,000.

● Mapangidwe aumunthu, mogwirizana ndi ergonomics, akugwira ntchito nthawi yaitali popanda kutopa.

Monga zodzikongoletsera za golidi ndi siliva pamsika zikucheperachepera komanso zosalimba, zovuta monga kusweka ndi kusweka nthawi zambiri zimachitika panthawi yopanga kapena kuvala.Thekukonza zodzikongoletseranthawi zambiri amafuna laser kuwotcherera luso.Zodzikongoletsera laser kuwotcherera makinaachita mbali yofunika kwambiri pamsika wamakampani awa.Chifukwa cha zodzikongoletsera zambiri zachitsulo, njira zambiri zimamalizidwa ndi luso lapamwamba la kuwotcherera kwa laser.

Ndiye n'chifukwa chiyani zodzikongoletsera ntchito laser kuwotcherera makina?Kodi zimasiyana bwanji ndi zaluso zapachikhalidwe?

Njira yopangira zodzikongoletsera ndi kusungunula chitsulo kutentha kwambiri, kenako kutenthetsa ndikuchikonza.Njira yowotcherera iyi nthawi zambiri imayambitsa kuyaka kwakuda muzodzikongoletsera, zomwe sizingachotsedwe kwathunthu ngakhale pambuyo poyeretsa, ndipo nthawi zina zimayambitsa zodzikongoletsera zokha.Kuwala kumachepa, zomwe zimakhudza kwambiri kukongola kwa zodzikongoletsera.Pakuti mavuto anakumana pokonza zodzikongoletsera kapena kukonza kuwotcherera laser, ndizodzikongoletsera laser kuwotcherera makinaakhoza kuthetsa vutoli mosavuta komanso mwamsanga.Ndi kusintha malo kuwala pa kuwotcherera malo zodzikongoletsera monga golide ndi siliva, kukulitsa malo kuwotcherera kudzera dzenje kuonerera, ndi kuchita processing pa udindo kukonzedwa malo kuwotcherera.

Kodi ubwino wa kugwiritsa ntchito laser malo kuwotcherera luso mu zodzikongoletsera processing ndi kukonza?

Kwenikweni, kuwotcherera laser malo ndi mtundu wa matenthedwe matenthedwe, amene ali ndi mphamvu yaing'ono matenthedwe pa zodzikongoletsera, ang'onoang'ono solder mfundo, ndipo sadzaipitsa mbali zina.Ubwino uwu umagwiritsidwanso ntchito kwambiri kuwotcherera mbali mwatsatanetsatane mwatsatanetsatane.Kuphatikiza apo, lusoli lidzagwirizananso ndi kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe kake.Imatha kuwongolera pafupipafupi komanso kulimba kwa kuwalako kuti zitsimikizire kuwotcherera kwazinthu zovuta kapena zambiri, kukulitsa kulondola kwa ntchito yowotcherera, ndikupewa kuwotcherera kwachikhalidwe pathupi la munthu.kuwonongeka kwa maso.

Ngati mukufuna kudziwa zambiri za makina owotcherera laser, kapena mukufuna kukugulirani makina opangira laser, chonde siyani uthenga patsamba lathu ndipo titumizireni imelo mwachindunji!

Nthawi yotumiza: Nov-26-2022