Ubucwebe begolide nesiliva bubalulekile empilweni yabantu, kodwa noma bungabiza kangakanani, budinga futhi ukucutshungulwa kwabantu ngokucophelela ukuze kubonakale umbala wabo ofanele.Kodwa-ke, kunendaba enzima kakhulu ekucubunguleni ubucwebe, okungukuthi,laser welding.Qaphela kakhulu lapho uthengisa, futhi udinga ukubona okuhle kakhulu.

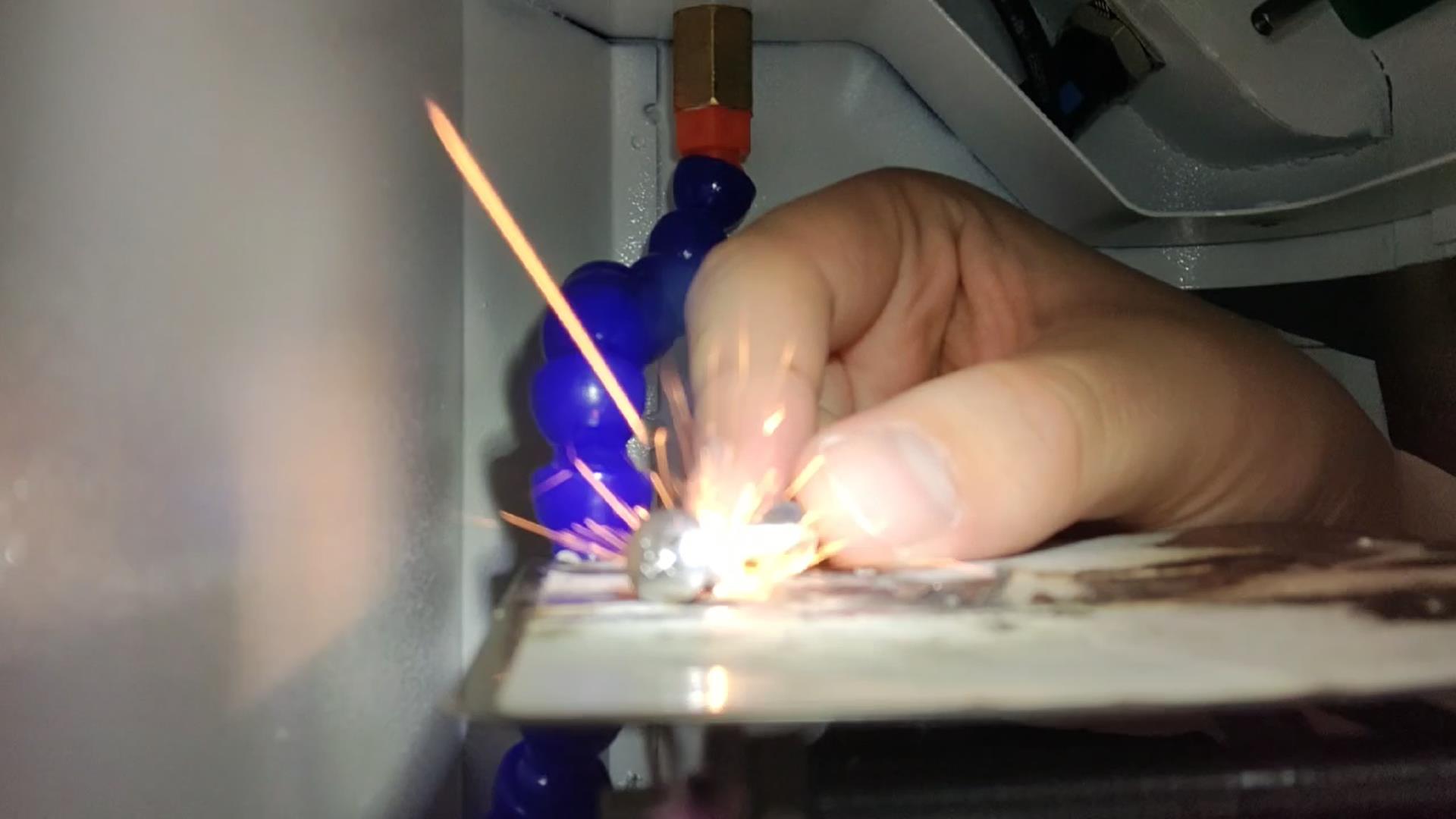

Jewelry laser spot welding umshiniisetshenziswa kakhulu ukulungisa izimbobo kanye namabhamuza okushisela ubucwebe begolide nobusiliva.I-laser spot welding ingenye yezici ezibalulekile zokusetshenziswa kobuchwepheshe bokucubungula izinto ze-laser.Ukushisa kusabalele ngaphakathi ngaphakathi ngokusebenzisa i-thermal conduction, futhi ngokulawula amapharamitha afana nobubanzi, amandla, amandla aphezulu kanye nemvamisa yokuphindaphinda kwe-laser pulse, i-workpiece iyancibilika ukuze yakhe ichibi elithile elincibilikisiwe.Ngenxa yezinzuzo zayo eziyingqayizivele, isetshenziswe ngempumelelo ekucubunguleni ubucwebe begolide nesiliva kanye nokushisela izingxenye ezincane nezincane.

Umshini wokushisela indawo we-laseryakhiwe ikakhulukazi i-laser, ukunikezwa kwamandla kanye nokulawula, umshini wokupholisa, umhlahlandlela wokukhanya nokugxila, kanye nokubhekwa kwe-binocular stereomicroscopic.Inokwakheka okuhlangene kanye nevolumu encane.Amandla e-laser, i-pulse frequency kanye nobubanzi be-pulse kungahlelwa futhi kushintshwe ngephaneli yokulawula.Ukunikezwa kwamandla kusebenzisa isakhiwo se-drawer, okulula ukusisusa, ngakho-ke imishini kulula ukuyisebenzisa nokuyigcina.Asikho isidingo sokugcwalisa i-solder, isivinini esiphezulu se-welding, ukuthintana okuthembekile, ukuguqulwa okuncane kwe-workpiece, ukwakheka okuhle.

Izici zomshini wokushisela we-laser ubucwebe:

● Amandla, ububanzi be-pulse, imvamisa, usayizi wendawo, njll. kungashintshwa kububanzi obubanzi ukuze kuzuzwe imiphumela ehlukahlukene yokushisela.Amapharamitha alungiswa ngama-levers ekamelweni elivaliwe, elula futhi ephumelelayo.

● Ukusebenzisa i-ceramic concentrator cavity engeniswe isuka e-UK, ekwazi ukumelana nokugqwala, izinga lokushisa eliphezulu, nokusebenza kahle kokuguqulwa kwesithombe sikagesi.

● Ukusebenzisa isistimu ye-shading ezenzakalelayo ethuthuke kakhulu emhlabeni ukuze kuqedwe ukucasuka kwamehlo ngesikhathi samahora okusebenza.

●Ngekhono lokusebenza eliqhubekayo lamahora angu-24, wonke umshini unokusebenza okuzinzile futhi awulungiswa phakathi kwamahora angu-10,000.

● Idizayini eyenziwe ngumuntu, ngokuhambisana ne-ergonomics, isebenza isikhathi eside ngaphandle kokukhathala.

Njengoba ubucwebe begolide nesiliva emakethe buya buba mncane futhi buntekenteke, izinkinga ezinjengokuphuka nokuphuka zivame ukwenzeka ngesikhathi sokukhiqiza noma sokugqoka.Iukulungiswa kobucwebengokuvamile kudinga ubuchwepheshe be-laser welding.Jewelry laser welding imishinibabe neqhaza elibalulekile emakethe yale mboni.Ngenxa yobucwebe bensimbi obuningi obuthambile, izinqubo eziningi ziqedwa ngobuchwepheshe obuphezulu be-laser welding.

Ngakho kungani ubucwebe zisebenzisa imishini yokushisela i-laser?Ihluke kanjani emisebenzini yezandla yesintu?

Inqubo yokukhiqiza ubucwebe bendabuko ukuncibilikisa insimbi ekushiseni okuphezulu, bese uyishisela bese uyicubungula.Le nqubo ye-welding ngokuvamile ibangela ukushisa okumnyama ebucwebeni, obungenakususwa ngokuphelele ngisho nangemva kokuhlanza kamuva, futhi ngezinye izikhathi kubangela ubucwebe bokuqala ngokwayo.I-gloss iyancipha, okuthinta kakhulu ubuhle bobucwebe.Ngezinkinga ezitholakala ekucubunguleni ubucwebe noma ukulungisa i-laser welding, ijewelry laser Welding umshiniingaxazulula inkinga kalula futhi ngokushesha.Iwukulungisa indawo yokukhanya endaweni yokushisela ubucwebe obufana negolide nesiliva, ukhulise indawo yokushisela ngembobo yokubuka, futhi wenze ukucubungula endaweni ezocutshungulwa ukushisela indawo.

Yiziphi izinzuzo zokusebenzisa ubuchwepheshe bokushisela indawo ye-laser ekucubunguleni ubucwebe nasekulungiseni?

Ngokuyisisekelo, i-laser spot welding iwuhlobo lwe-conductivity eshisayo, enethonya elincane elishisayo kubucwebe, amalunga amancane e-solder, futhi ngeke angcolise ezinye izingxenye.Le nzuzo ibuye isetshenziswe kabanzi ekushiseni kwezingxenye zokunemba ngokunemba.Ngaphezu kwalokho, lobu buchwepheshe buzophinde bubambisane nokulawulwa kwesistimu ukuze kuthuthukiswe ukusebenza okuzinzile komshini kanye nemishini.Ingakwazi ukulawula ukuvama nokuqina kokukhanya ukuze kuqinisekiswe umphumela wokushisela wezakhiwo eziyinkimbinkimbi noma imininingwane, ithuthukise ukunemba komsebenzi wokushisela, futhi igweme ukushisela kwendabuko emzimbeni womuntu.ukulimala kwamehlo.

Uma ufuna ukufunda okwengeziwe ngomshini we-laser welding, noma ufuna ukukuthengela umshini wokushisela we-laser, sicela ushiye umlayezo kuwebhusayithi yethu futhi usithumele i-imeyili ngqo!

Isikhathi sokuthumela: Nov-26-2022