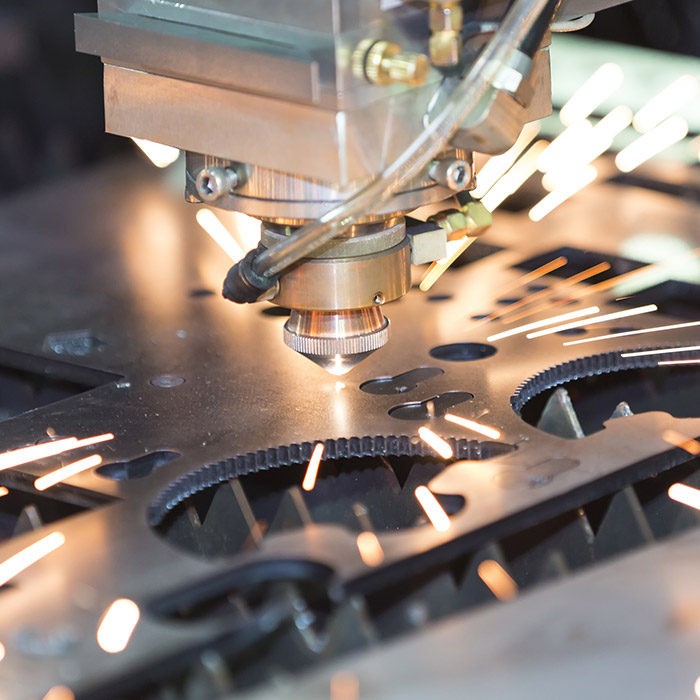

Laser sabon, kuma aka sani da Laser katako sabon ko CNC Laser sabon, ne thermal sabon tsari da aka akai-akai amfani da takardar karfe aiki.

Lokacin zabar tsarin yanke don aikin ƙirar ƙarfe, yana da mahimmanci a yi la'akari da ƙarfin kayan aikin da kuka zaɓa bisa la'akari da bukatun aikinku. Domin da yawa ƙirƙira ayyukan ta yin amfani da takardar karfe, Laser sabon ne mafi zabi. Ga wasu abũbuwan amfãni ga Laser sabon inji kana bukatar ka sani.

Dangantakar Ƙananan Farashi

Idan aka kwatanta da sauran hanyoyin yankan, yankan Laser yana da tasiri sosai. Tare da tsarin sarrafa kansa na CNC, farashin aiki ba su da yawa, kuma injinan suna da sauƙin aiki. Bugu da ƙari, Laser ba ya yin rauni ko sawa kamar sauran kayan aikin yankan. Saboda wannan dalili, babu wani canji mai mahimmanci a tsakiyar tsari, yana haifar da mafi kyawun aiki da ɗan gajeren lokacin jagora. Lokacin da akwai ƙarancin katsewa a cikin tsarin yanke, farashi zai zama ƙasa.

Babban Gudu da inganci

Laser na iya yanke kayan cikin sauri. Madaidaicin saurin zai dogara ne akan ikon laser, nau'in kayan abu da kauri, juriya da rikice-rikice na sassan. Duk da haka, suna motsawa da sauri idan aka kwatanta da sauran kayan aikin yankan. Baya ga saurin yankan sauri, masu yankan Laser na iya yin aiki na dogon lokaci, suna haɓaka ingantaccen tsarin yanke.

Automation / CNC Control

Ɗaya daga cikin fa'idodin yankan Laser shine cewa injinan gaba ɗaya suna sarrafa su ta hanyar sarrafa CNC, wanda ke haifar da sassa da samfuran da ba su da ɗan bambanci da ƙarancin lahani. Automation kuma yana nufin cewa ƙarancin aikin da ake buƙata don sarrafa na'ura da gudanar da ayyukanta, yana sa tsarin ya fi dacewa. Aiwatar da tsarin yankewa ta atomatik yana haifar da ingantaccen inganci, samfuran inganci masu inganci, da ƙarancin ɓarna na raguwa. Bayan da 2D yankan, da Laser cutters kuma dace da 3D sabon. Injin suna da kyau don ƙirƙirar samfura, ƙira da ƙira, bututu, bututu, ƙwanƙolin ƙarfe, faɗaɗɗen ƙarfe, kayan kwalliyar lebur, da ƙari.

Babban Madaidaici

Masu yankan Laser suna da cikakkun bayanai dalla-dalla, suna iya ƙirƙirar ƙananan yanke da kuma jure juriya. Suna haifar da tsabta, kaifi, da santsi da gefuna da lankwasa. Babban yanke ƙare. Za su kuma samar da kadan (ko da babu) burring saboda Laser narke kayan, maimakon yanke shi. Masu yankan Laser suna da kyau don sarrafa ƙarfe na takarda saboda suna da madaidaicin gaske kuma za su haifar da ingantattun yankewa masu inganci.

Farashin aiki, saurin na'ura, da sauƙin sarrafawa na CNC yana sa masu yankan Laser su dace da mafi yawan samfuran girma da ayyuka. Saboda masu yankan Laser daidai ne kuma daidai, zaku iya tabbatar da cewa sakamakon ƙarshe yana da inganci. Laser cutters iya yanke ta cikin wani m iri-iri na karfe kayan, ciki har da aluminum, tagulla, jan karfe, m karfe, carbon karfe, bakin karfe, da dai sauransu sanya shi manufa zabin ga sheet karfe ƙirƙira. Injin ɗin na iya ɗaukar matsananciyar haƙuri da ƙirƙira ƙira, tabbatar da cewa kowane aikin yana cikin isar su.

Barka da zuwa tuntuɓar Fortune Laser don ƙarin cikakkun bayanai game da injunan yankan Laser na ƙarfe don aikin ƙirar ƙirar ku a yau!

TA YAYA ZAMU IYA TAIMAKO A YAU?

Da fatan za a cika fom ɗin da ke ƙasa kuma za mu dawo gare ku da wuri-wuri.