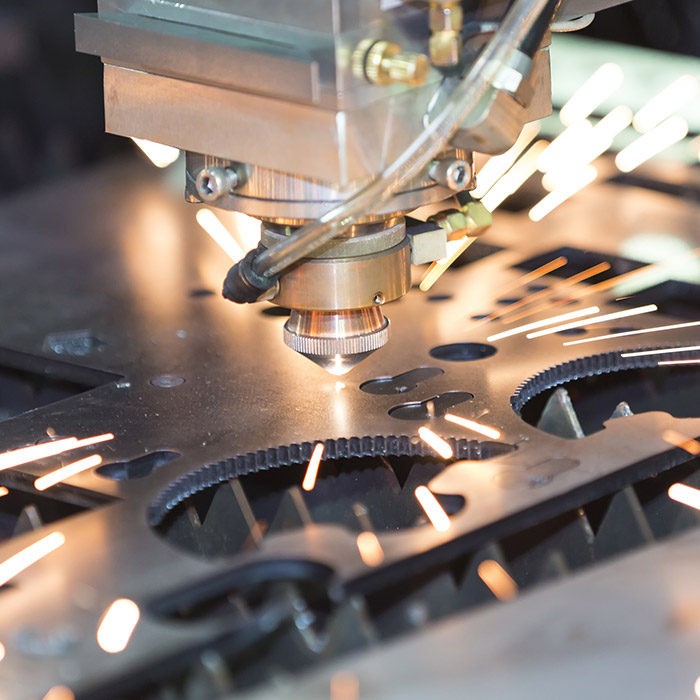

Ukusika i-laser, eyaziwa nangokuthi ukusika kwe-laser beam noma i-CNC laser cutting, inqubo yokusika okushisayo evame ukusetshenziswa ekucubunguleni insimbi yeshidi.

Lapho ukhetha inqubo yokusika yephrojekthi yokwenziwa kwensimbi yeshidi, kubalulekile ukucabangela amandla ethuluzi olikhethayo ngokusekelwe ezidingweni zephrojekthi yakho.Kumaphrojekthi amaningi wokwenza usebenzisa i-sheet metal, ukusika i-laser kuyisinqumo esingcono.Nazi ezinye izinzuzo zemishini yokusika i-laser okudingeka ukwazi.

Izindleko Eziphansi Ngokuqhathaniswa

Uma kuqhathaniswa nezinye izindlela zokusika, ukusika kwe-laser kubiza kakhulu.Ngohlelo oluzishintshayo lwe-CNC oluhilelekile, izindleko zabasebenzi zincane, futhi imishini kulula kakhulu ukuyisebenzisa.Ukwengeza, i-laser ayibi buthuntu noma igqokwe njengamanye amathuluzi okusika.Ngenxa yalesi sizathu, alukho ushintsho oludingekayo phakathi nenqubo, okuholela ekukhiqizeni okungcono kanye nesikhathi sokuhola esifushane.Uma kunokuphazamiseka okuncane ohlelweni lokusika, izindleko zizoba ngaphansi.

Isivinini esikhulu nokusebenza kahle

Ama-Lasers anganqamula izinto ngokushesha okukhulu.Ijubane eliqondile lizoncika emandleni e-laser, uhlobo lwempahla nokushuba, ukubekezelela kanye nobunkimbinkimbi bezingxenye.Nokho, zihamba ngokushesha kakhulu uma ziqhathaniswa namanye amathuluzi okusika.Ngaphezu kwesivinini sokusika ngokushesha, abasiki be-laser bangasebenza isikhathi eside, bakhulise ukusebenza kahle okuphelele kwenqubo yokusika.

I-Automation / CNC Control

Enye yezinzuzo zokusika nge-laser ukuthi imishini ilawulwa ngokuphelele yi-CNC controls, okuholela ezingxenyeni kanye nemikhiqizo enokuhlukahluka okuncane noma okungekho kanye namaphutha ambalwa kakhulu.I-automation ibuye isho ukuthi umsebenzi omncane odingekayo ukuze usebenzise umshini nokwenza imisebenzi yawo, okwenza inqubo isebenze kahle.Ukuzenzakalela kwenqubo yokusika kuholela ekusebenzeni kahle okukhulu, imikhiqizo yekhwalithi ephezulu, kanye nokumosha okuncane kakhulu kwezinsalela.Ngaphandle kokusika kwe-2D, abasiki be-laser nabo bafanele ukusika kwe-3D.Imishini ifaneleka kahle ekwakhiweni kwama-prototypes, amamodeli nesikhunta, ipayipi, ishubhu, izinsimbi zikathayela, insimbi enwetshiwe, isitokwe seshidi eliyisicaba, nokunye.

Ukunemba okuphezulu

Abasiki be-Laser banamandla anemininingwane eminingi, abakwazi ukudala ukusikeka okuncane nokubekezelelana okuqinile.Bakha imiphetho namajika ahlanzekile, abukhali, futhi abushelelezi.Ukuqedwa okuphezulu.Bazophinde bakhiqize ukushiswa okuncane (ngisho noma cha) ngoba i-laser iyancibilikisa impahla, kunokuba isike.Ama-Laser cutters afaneleka kakhulu ekucubunguleni insimbi yeshidi ngoba anembe kakhulu futhi azodala ukusikeka okunembile, kwekhwalithi ephezulu.

Izindleko zokusebenza, isivinini somshini, nokusebenza okulula kokulawula kwe-CNC kwenza abasiki be-laser bafaneleke emikhiqizweni eminingi yosayizi namaphrojekthi.Ngenxa yokuthi abasiki be-laser banembile futhi banembile, ungaqiniseka ukuthi umphumela ungowekhwalithi ephezulu.Abasiki be-laser bangakwazi ukusika izinto ezihlukahlukene zensimbi, okuhlanganisa i-aluminium, ithusi, ithusi, insimbi emnene, i-carbon steel, insimbi engagqwali, njll. okwenza kube inketho ekahle yokwenziwa kweshidi lensimbi.Imishini ingabhekana nokubekezelelana okuqinile nemiklamo eyinkimbinkimbi, iqinisekisa ukuthi noma iyiphi iphrojekthi ifinyeleleka kalula.

Siyakwamukela ukuthintana ne-Fortune Laser ukuze uthole imininingwane eyengeziwe mayelana nemishini yokusika i-laser yensimbi yephrojekthi yakho yokwenza amashidi ensimbi namuhla!