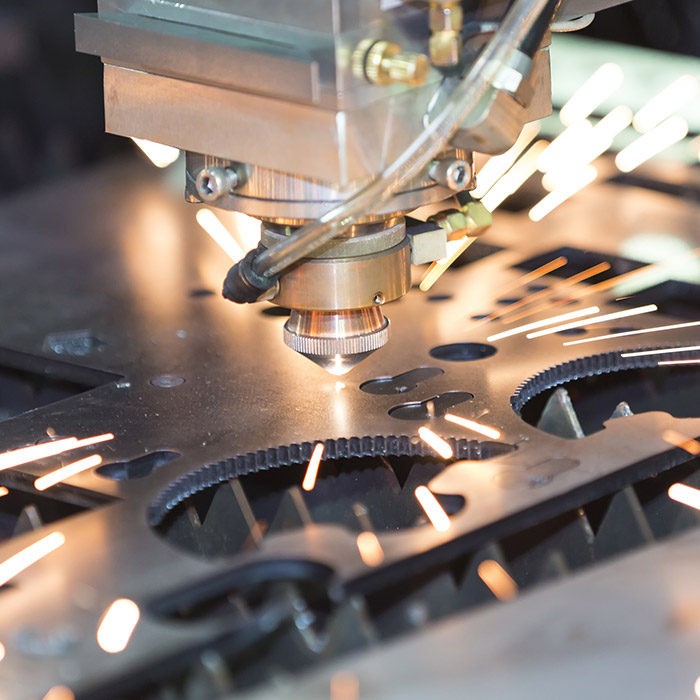

Ukusika i-laser, eyaziwa ngokuba yi-laser beam cutting okanye i-CNC laser cutting, yinkqubo yokusika i-thermal esetyenziswa rhoqo kwi-sheet metal processing.

Xa ukhetha inkqubo yokusika iprojekthi yokwenziwa kwesinyithi, kubalulekile ukuqwalasela amandla esixhobo osikhethayo ngokusekelwe kwiimfuno zeprojekthi yakho.Kwiiprojekthi ezininzi zokwenziwa usebenzisa i-sheet metal, ukusika i-laser lukhetho olungcono.Nazi ezinye iingenelo koomatshini ukusika laser kufuneka uyazi.

Iindleko eziphantsi ngokwentelekiso

Xa kuthelekiswa nezinye iindlela zokusika, ukusika i-laser kubiza kakhulu.Ngenkqubo ye-automation ye-CNC ebandakanyekayo, iindleko zabasebenzi zincinci, kwaye oomatshini balula kakhulu ukusebenza.Ukongeza, i-laser ayidinwa okanye inxibe njengezinye izixhobo zokusika.Ngesi sizathu, akukho mfuneko yotshintsho oluphakathi kwenkqubo, ekhokelela kwimveliso engcono kunye nexesha elifutshane lokukhokela.Xa kukho ukuphazamiseka okuncinci kwinkqubo yokusika, iindleko ziya kuba ziphantsi.

Isantya esiphezulu kunye nokusebenza kakuhle

I-Lasers inokusika izixhobo ngokukhawuleza.Isantya esichanekileyo siya kuxhomekeka kumandla e-laser, uhlobo lwezinto eziphathekayo kunye nobukhulu, ukunyamezela kunye nobuqili bamacandelo.Nangona kunjalo, zihamba ngokukhawuleza xa zithelekiswa nezinye izixhobo zokusika.Ukongeza kwizantya zokusika ngokukhawuleza, i-laser cutters inokusebenza ixesha elide, ukwandisa ukusebenza kakuhle kwenkqubo yokusika.

Ukuzenzekela / Ulawulo lwe-CNC

Enye yeenzuzo zokusikwa kwe-laser kukuba oomatshini baqhutywa ngokupheleleyo lulawulo lwe-CNC, olukhokelela kwiindawo kunye neemveliso ezingenazo iinguqu ezincinci kunye neziphene ezimbalwa kakhulu.Ukuzenzekela kwakhona kuthetha ukuba umsebenzi omncinci uyimfuneko ekusebenzeni umatshini kunye nokwenza imisebenzi yawo, okwenza inkqubo isebenze ngakumbi.Ukuzenzekela kwenkqubo yokusika kukhokelela ekusebenzeni kakuhle, iimveliso ezikumgangatho ophezulu, kunye nenkcitho encinci yenkunkuma.Ngaphandle kokusika kwe-2D, abasiki be-laser nabo bafanelekile ukusika i-3D.Oomatshini bakulungele ukwenza iprototypes, iimodeli kunye nokubumba, umbhobho, ityhubhu, isinyithi esinamacangci, isinyithi esandisiweyo, isitokhwe seshiti esicaba, kunye nokunye.

Ukuchaneka okuphezulu

Abasiki beLaser banobuchule obucacileyo, bayakwazi ukwenza amanxeba amancinci kunye nokunyamezelana okuqinileyo.Benza imiphetho ecocekileyo, ebukhali, kwaye egudileyo kunye neegophe.Ukugqiba okuphezulu.Baya kuvelisa okuncinci (nokuba akukho) ukuvutha ngenxa yokuba i-laser iyanyibilika izinto eziphathekayo, kunokuba zisike.Abasiki beLaser bafaneleka kakhulu ukusetyenzwa kwesinyithi kuba bachane kakhulu kwaye baya kudala ukusika okuchanekileyo, okukumgangatho ophezulu.

Iindleko zokusebenza, isantya somatshini, kunye nokusebenza lula kolawulo lwe-CNC kwenza abasiki be-laser balungele uninzi lweemveliso zobungakanani kunye neeprojekthi.Ngenxa yokuba ii-laser cutters zichanekile kwaye zichanekile, unokuqiniseka ukuba isiphelo sikumgangatho ophezulu.Abasiki be-Laser banokunqumla kwiintlobo ezininzi zezixhobo zetsimbi, kubandakanywa i-aluminium, ubhedu, ubhedu, insimbi epholileyo, i-carbon steel, insimbi engenasici, njl.Oomatshini banokumelana nokunyamezelana okuqinileyo kunye noyilo oluntsonkothileyo, beqinisekisa ukuba nayiphi na iprojekthi inokufikeleleka kubo.

Wamkelekile ukuba uqhagamshelane ne-Fortune Laser ngeenkcukacha ezithe kratya malunga noomatshini bokusika i-laser yesinyithi kwiprojekthi yakho yokwenza iphepha lesinyithi namhlanje!