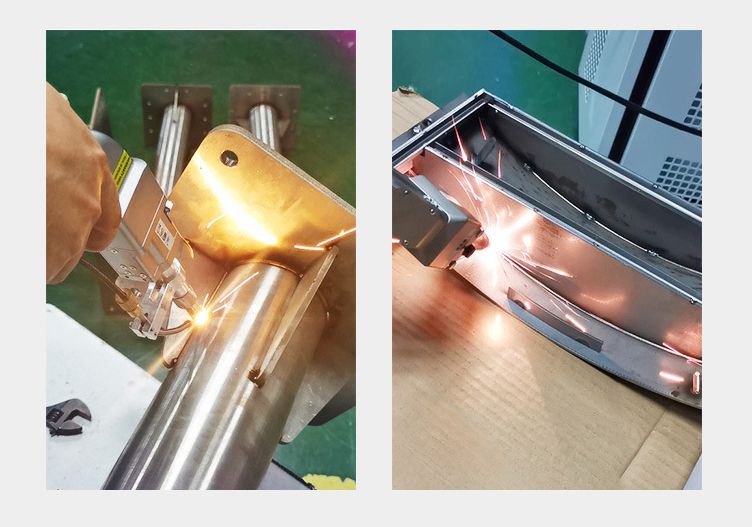

At present, in the field of metal welding, hand-held laser welding machines are widely used. Basically, metals that can be welded by traditional welding can be welded by laser, and the welding effect and speed will be better than traditional welding processes. Traditional welding is difficult to weld non-ferrous metal materials such as aluminum alloy, but laser welding has a wider range of applications, and aluminum alloy and other materials can also be easily welded.

The laser beam has sufficient power density, and is projected onto the object through the optical fiber, correspondingly absorbed and reflected, and the absorbed light energy will complete the corresponding heat conversion, diffusion, conduction, delivery and radiation, and the object will be affected by the light to generate corresponding heating - Melting - Vaporization - Changes in metal microfacets.

The application range of handheld laser welding machines is becoming wider and wider. It is used in kitchen and bathroom cabinets, stainless steel furniture, distribution boxes, stainless steel door and window guardrails, and stairs and elevators. When using it, you need to pay special attention to safety.

So what are the precautions for the safe use of handheld laser welding machines?

1. When using a hand-held laser welding machine, the operator must undergo strict training before working on the job. The laser cannot hit people or surrounding objects, otherwise it may bring very serious consequences. , such as burns, or fires, this is very dangerous, everyone must pay special attention to safety.

2. Although the welding process of the handheld laser welding machine is operated against the workpiece, it will still produce high-brightness reflections. Therefore, the operator must be equipped with special protective light goggles to protect their eyes. If they do not wear goggles, It is not allowed to operate a handheld laser welding machine.

3. When using a handheld laser welding machine, regularly check the wiring part of the power wiring. At the positions of the input side and the output side, as well as the wiring parts of the external wiring and the wiring parts of the internal wiring, etc., it is necessary to carefully check whether there is any looseness of the wiring screws. If rust is found, the rust should be promptly removed. Remove to maintain good electrical conductivity and prevent electric shock accidents.

4. Put on the insulating ferrule. The use of a handheld laser welding machine also requires an insulating ferrule, so that the gas can flow out evenly, otherwise the welding torch may burn out due to a short circuit.

When you use the handheld laser welding machine, you can refer to the above method to operate, so as to ensure the safety of use and avoid accidents as much as possible. The laser equipment will cause a certain loss during use, and proper maintenance can reduce the loss and failure. This requires regular inspection of laser equipment.

What are the maintenance precautions for handheld laser welding machines and chillers?

1. Regularly check the power supply of the equipment. Whether the wiring is loose, whether the wire insulation is loose or peeled off.

2. Regularly clean up the dust. The working environment of the welding machine is dusty, and the dust inside the welding machine can be cleaned regularly. The gaps between the reactance coil and coil coils, and the power semiconductors should be especially cleaned. The chiller needs to clean the dust on the dust screen and the fins of the condenser.

3. The welding torch is an important part of the welding machine, which should be checked and replaced regularly. Due to wear and tear, the aperture of the nozzle becomes larger, which will cause arc instability, deterioration of the appearance of the weld or sticking wire (burning back); the end of the contact tip is stuck to spatter, and the wire feeding will become uneven; the contact tip is not tightened tightly. , the threaded connection will heat up and be welded dead. A damaged torch should be replaced regularly. The chiller needs to replace the circulating water about once a month.

4. Pay attention to the ambient temperature. The temperature of the operating environment of the welding torch and the chiller should not be too high, one will affect the heat dissipation and cooling of the chiller, and the other will affect the normal operation of the welding machine. Especially in the hot summer, more attention should be paid to the room temperature, and the equipment should be operated in a ventilated place as much as possible. The temperature in winter should not be too low, if the circulating water temperature is too low, the chiller cannot be started.

After daily maintenance is done, the welding quality of the handheld laser welding machine is better, the cooling effect of the chiller is better, and the service life can be extended.

The above is the key point of how to carry out daily maintenance of the handheld laser welding machine. It should be noted that when using the handheld laser welding machine, the operator must undergo professional training to understand the specific use of each system indicator light and each button, and be familiar with the most basic equipment knowledge .

If you want to learn more about laser welding, or want to buy the best laser welding machine for you, please leave a message on our website and email us directly!

Post time: Jan-10-2023