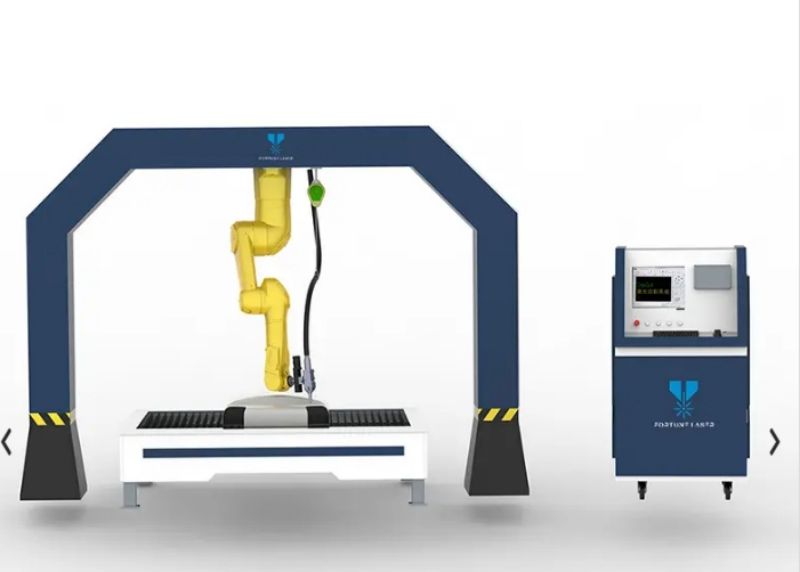

In today's rapidly evolving technological world, the requirements for precision and efficiency in manufacturing processes have never been higher. Gantry laser cutting machines have become a reliable and efficient solution with numerous advantages over traditional cutting methods. Gantry laser cutting machines have revolutionized the manufacturing industry by cutting a variety of materials with high precision and quality.

One of the main advantages of gantry laser cutting machines is their high efficiency. These machines are designed to deliver impressive cutting speeds, resulting in fast, accurate production. The use of advanced laser technology ensures that the cutting process is fast and efficient, significantly reducing the time required for manufacturing. In addition, the gantry laser cutting machine is equipped with a high-power laser that can easily cut thick materials, further improving efficiency.

In addition, gantry laser cutting machines are known for their excellent cutting quality. These machines use a non-contact cutting method that eliminates physical contact between the torch and the workpiece. This results in clean, precise cuts without any distortion or imperfections. The laser beam is focused only on the desired cutting area, ensuring a smooth, accurate finish. Unlike other cutting methods such as oxyacetylene cutting and plasma cutting, gantry laser cutting machines provide superior cut quality and can meet even the most complex manufacturing requirements.

Unlike traditional cutting methods that often require different tools for different materials, gantry laser cutters offer unparalleled versatility. These machines can cut a variety of materials, including metals, non-metals, metal-based and non-metal-based composites, leather, wood and fibers. This tremendous flexibility makes gantry laser cutting machines ideal for various industries to meet different manufacturing needs. Be it stainless steel, acrylic, or even delicate fabrics, these machines can handle it all, providing a one-stop solution for your cutting requirements.

Additionally, gantry laser cutting machines offer a non-contact cutting method that eliminates tool wear. Traditional cutting methods often require the use of sharp tools that wear out over time, resulting in a loss of cut quality. However, with a gantry laser cutting machine, there is no direct contact between the cutting torch and the workpiece, ensuring that the laser remains the only tool used. This eliminates the need for frequent tool changes, reducing downtime and maintenance costs.

Using a gantry laser cutting machine also minimizes noise, vibration and contamination during the cutting process. Traditional cutting methods often produce excessive noise and vibration, resulting in a poor working environment. The gantry laser cutting machine, on the other hand, operates quietly, creating a quiet and safe working atmosphere. Additionally, these machines produce minimal vibration, ensuring stability and accuracy in the cutting process. Additionally, because the gantry laser cutting machine uses a non-contact cutting method, no harmful fumes or debris are produced, resulting in a cleaner, healthier work environment.

In summary, gantry laser cutting machines offer many advantages over traditional cutting methods. These machines have revolutionized the manufacturing industry with their high efficiency, good cut quality, non-contact cutting, and versatility in cutting a variety of materials. Gantry laser cutting machines can cut different materials accurately and quickly, making them an indispensable tool in industries ranging from automotive to fashion. Additionally, non-contact cutting methods and elimination of tool wear save costs and increase productivity. Low noise, low vibration and low pollution levels ensure a comfortable working environment. As technology continues to advance, gantry laser cutters will only become more sophisticated, further enhancing their advantages and cementing their position as the go-to solution for precise and efficient cutting.

Post time: Oct-31-2023