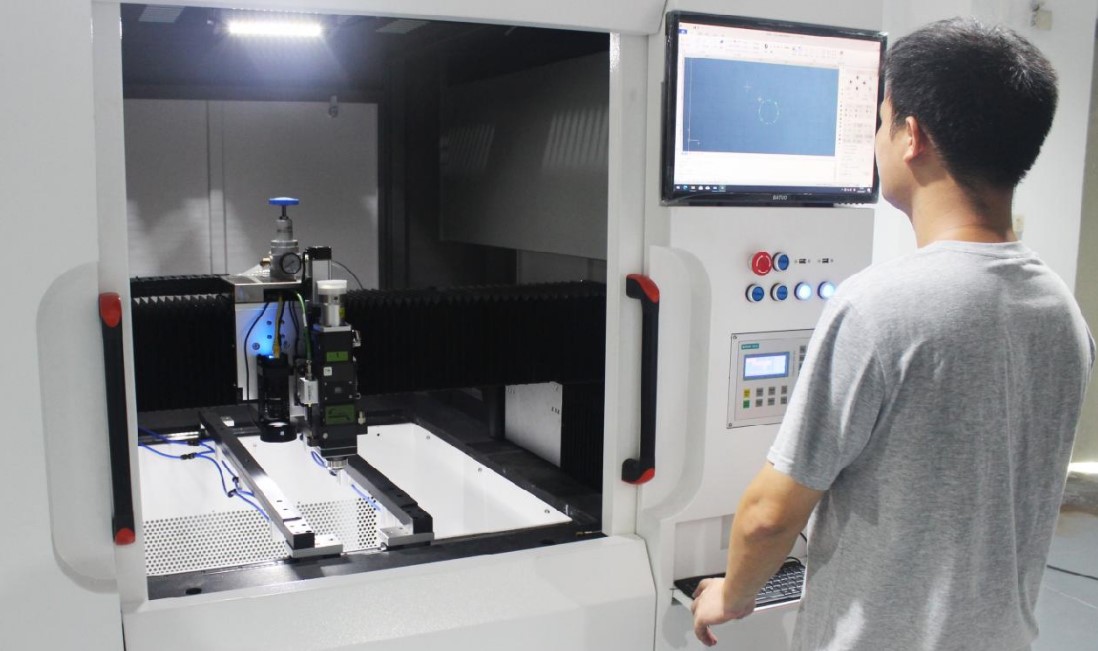

Fortune Laser Pulse Air Cooling 200W/300W Mini Laser Cleaning Machine

Fortune Laser Pulse Air Cooling 200W/300W Mini Laser Cleaning Machine

What kind of latest technological developments have been achieved in the field of laser cleaning machines?

Laser cleaning machine is a kind of cleaning equipment widely used in various industries. It has significant advantages in cleaning effect, speed and environmental protection. The latest technological developments demonstrate product innovation and forward-lookingness in the following aspects:

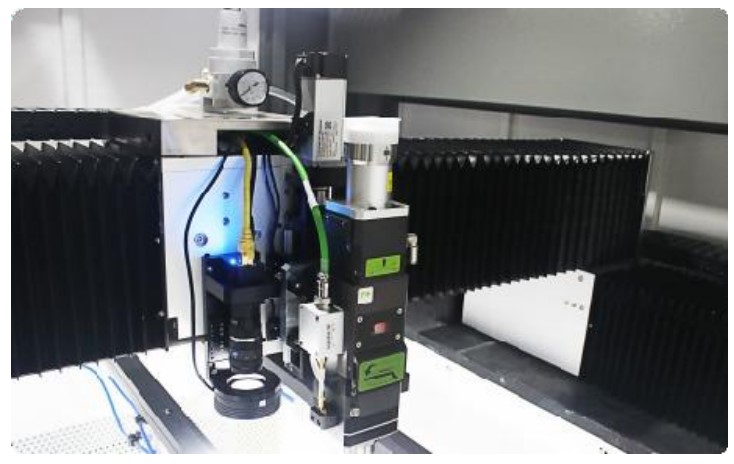

(1) High-energy laser technology: This technology provides laser cleaning machines with more powerful cleaning capabilities. Using high-energy laser beams, a variety of surfaces can be cleaned more deeply, including materials such as metals, ceramics, and plastics. High-energy lasers quickly remove stains, grease and coatings while maintaining the integrity of surfaces.

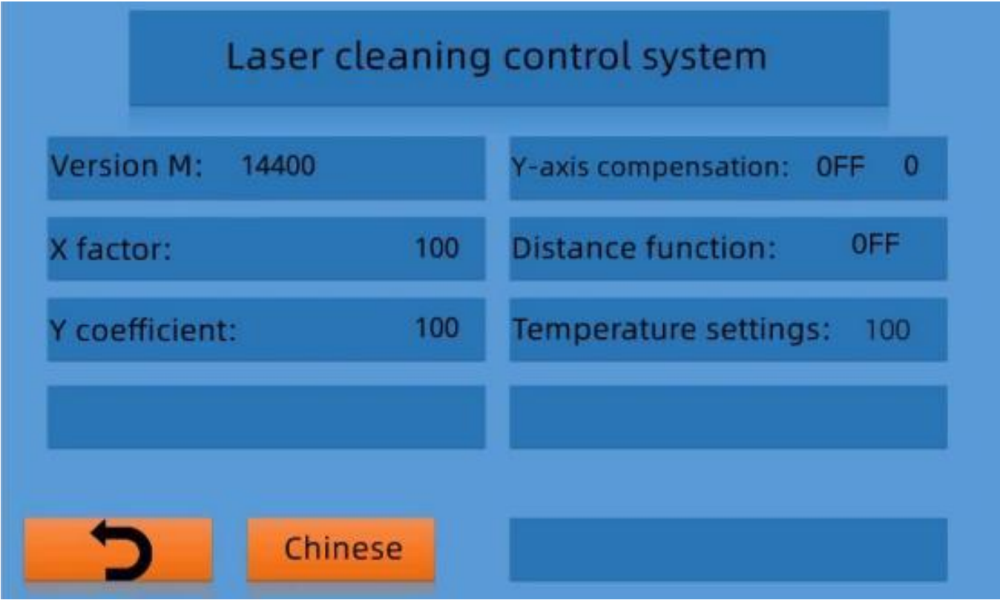

(2) High-precision positioning system: Modern laser cleaning machines are equipped with a high-precision positioning system to ensure that the cleaning process is accurate to every detail. By using high-precision cameras, sensors and algorithms, laser cleaning machines can intelligently identify and position objects based on the shape and contours of their surfaces, resulting in more refined and consistent cleaning results.

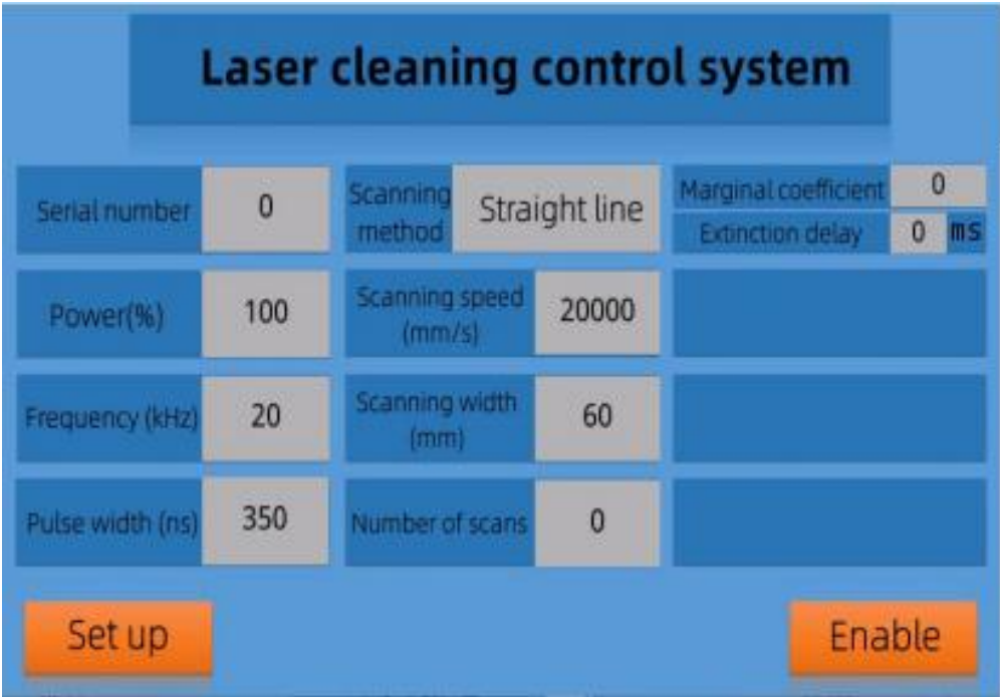

(3) Adaptive cleaning mode: The innovative adaptive cleaning mode allows the laser cleaning machine to automatically adjust the cleaning process based on the characteristics of the object surface and the degree of stains. Through real-time monitoring and feedback mechanisms, laser cleaning machines can adjust the power, speed and area of the laser beam as needed to achieve optimal cleaning results while minimizing waste of energy and materials.

(4) Environmentally friendly performance: Laser cleaning machines do not require the use of chemical cleaners or large amounts of water during the cleaning process, so they have significant environmentally friendly performance. It can effectively remove stains without polluting the environment, reducing dependence on chemical cleaners and saving water use. This environmentally friendly performance makes laser cleaning machines a sustainable cleaning solution.