Fortune Laser Handheld Fiber Laser Vuam Tshuab

Fortune Laser Handheld Fiber Laser Vuam Tshuab

Fortune Laser Handheld Laser Welder Technical Parameters

| Qauv | FL-HW 1000 | FL-HW 1500 | FL-HW 2000 |

| Hom Laser | 1070nm Fiber Laser tej tshuab | ||

| Nominal Laser zog | 1000 W | 1500 W | 2000 W |

| Txias System | Dej Txias | ||

| Txoj kev ua haujlwm | Nruam / Modulation | ||

| Ceev ntau ntawm welder | 0 ~ 120 hli / s | ||

| Focal Spot Diameter | 0.5 hli | ||

| Ambient kub ntau yam | 15 ~ 35 ℃ | ||

| Environmental humidity ntau | <70% tsis muaj condensation | ||

| Vuam thickness | 0.5-1.5 hli | 0.5-2 hli | 0.5-3 hli |

| Vuam qhov sib txawv yuav tsum | ≤1.2 hli | ||

| Kev khiav hauj lwm voltage | AC 220V / 50HZ 60HZ / 380V ± 5V 50HZ 60HZ 60A | ||

| Txee Dimension | 120 * 60 * 120cm | ||

| Ntoo Pob Dimension | 154 * 79 * 137cm | ||

| Qhov hnyav | 285 KG | ||

| Fiber ntev | Standard 10M, qhov ntev customized ntev yog 15M | ||

| Daim ntawv thov | Vuam thiab kho stainless hlau, carbon steel, aluminium alloy. | ||

Portable Handheld Laser Welder rau Hlau

| Khoom siv | Lub zog tso zis (W) | Kev nkag siab siab tshaj plaws (mm) |

| Stainless hlau | 1000 | 0.5-3 |

| Stainless hlau | 1500 | 0.5-4 |

| Stainless hlau | 2000 | 0.5-5 |

| Cov pa roj carbon steel | 1000 | 0.5-2.5 hli |

| Cov pa roj carbon steel | 1500 | 0.5-3.5 hli |

| Cov pa roj carbon steel | 2000 | 0.5-4.5 hli |

| Aluminium alloy | 1000 | 0.5-2.5 hli |

| Aluminium alloy | 1500 | 0.5-3 |

| Aluminium alloy | 2000 | 0.5-4 |

| Galvanized ntawv | 1000 | 0.5-1.2 hli |

| Galvanized ntawv | 1500 | 0.5-1.8 hli |

| Galvanized ntawv | 2000 | 0.5-2.5 hli |

Peb Xim rau koj xaiv

Qhov zoo ntawm Handheld Laser Vuam Tshuab

1. Dav vuam ntau yam:

Lub tes tuav lub taub hau yog nruab nrog 10M thawj optical fiber (qhov ntev tshaj plaws customized ntev yog 15M), uas kov yeej cov kev txwv ntawm qhov chaw ua hauj lwm, thiab tuaj yeem welded sab nraum zoov thiab ntev vuam;

2. Yooj yim thiab yoog raws siv:

Tes tuav laser welding yog nruab nrog movable pulleys, uas yooj yim los tuav, thiab tuaj yeem kho qhov chaw nres tsheb txhua lub sijhawm, tsis muaj qhov chaw nres tsheb ruaj khov, dawb thiab hloov pauv, thiab tsim nyog rau ntau qhov chaw ua haujlwm.

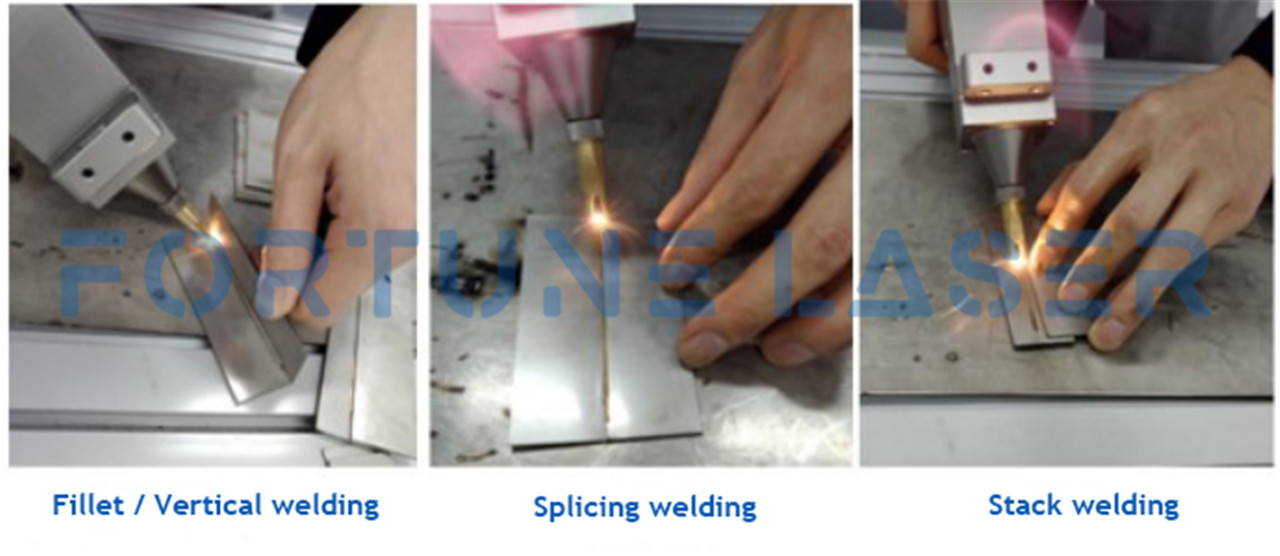

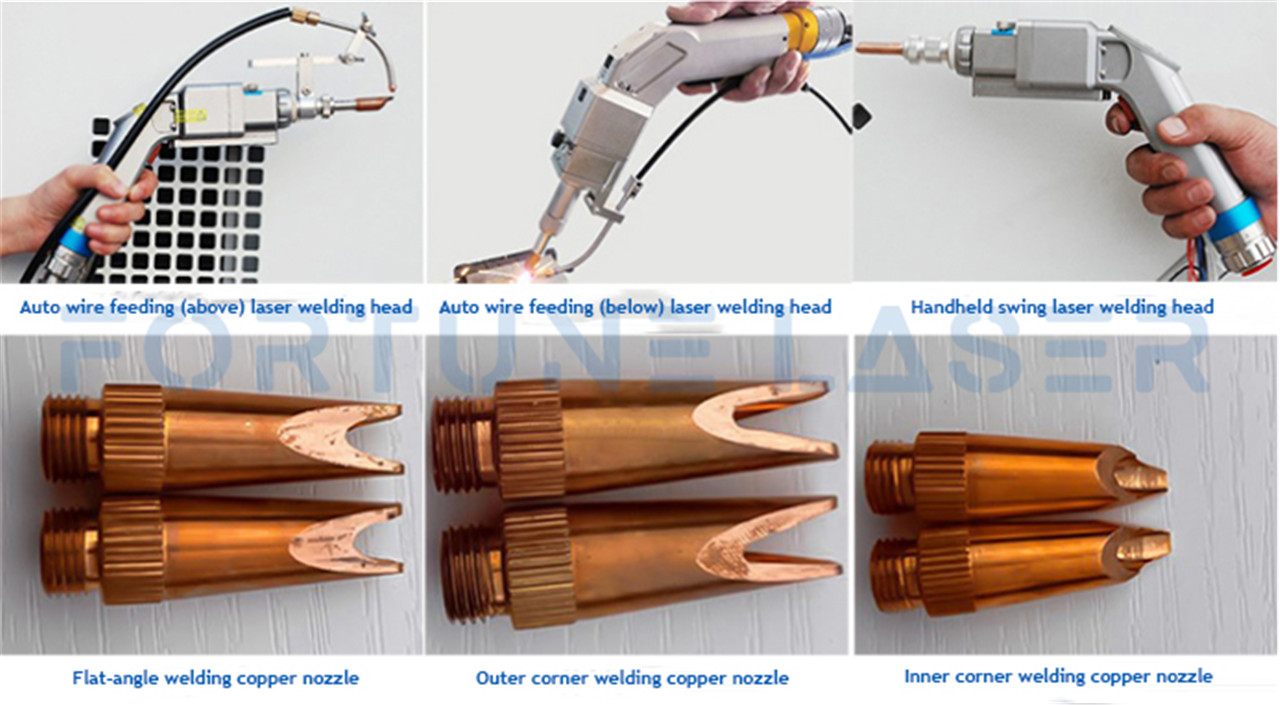

3. Ntau txoj kev vuam:

Vuam ntawm txhua lub kaum ntse ntse tuaj yeem pom tau: sib tshooj vuam, taub qab vuam, ntsug vuam, tiaj tus vuam vuam, sab hauv cov hlua vuam, sab nraud vuam vuam, thiab lwm yam, thiab tuaj yeem vuam ntau yam welded workpieces thiab loj workpieces nrog irregular shapes.Paub welding ntawm txhua lub kaum ntse ntse.Tsis tas li ntawd, nws tseem tuaj yeem ua tiav qhov txiav, vuam thiab txiav tuaj yeem hloov pauv dawb, tsuas yog hloov cov vuam tooj liab nozzle rau txiav tooj liab nozzle, uas yooj yim heev.

4. Cov nyhuv vuam zoo:

Tes tuav laser vuam yog thermal fusion vuam.Piv nrog rau cov tsoos welding, laser vuam muaj lub zog ntau dua thiab tuaj yeem ua tiav cov txiaj ntsig zoo dua.Qhov chaw vuam muaj qhov cuam tshuam me ntsis thermal, tsis yooj yim rau deform, dub, thiab muaj kab nyob tom qab.Lub vuam qhov tob yog loj, lub melting yog txaus, thiab nws yog ruaj khov thiab txhim khu kev qha, thiab lub zog vuam ncav cuag los yog tshaj lub hauv paus hlau nws tus kheej, uas tsis tuaj yeem lav tau los ntawm cov tshuab vuam zoo tib yam.

5. Vuam seam tsis tas yuav polished.

Tom qab ib txwm welding, lub vuam taw tes yuav tsum tau polished los xyuas kom meej tias nws yog du thiab tsis ntxhib.Lub tes tuav laser vuam precisely qhia txog qhov zoo ntawm kev ua cov nyhuv: nruam vuam, du thiab tsis muaj ntses nplai, zoo nkauj thiab tsis muaj caws pliav, thiab tsawg dua cov txheej txheem polishing.

6. Vuam nrogtsis siv neeg hlau feeder.

Nyob rau hauv feem ntau cov neeg lub tswv yim, lub vuam ua hauj lwm yog "sab laug tes tsom iav, sab tes clamp vuam hlau".Tab sis nrog lub handheld laser vuam tshuab, vuam tuaj yeem ua tiav yooj yim, uas txo cov nqi khoom hauv kev tsim khoom thiab kev ua haujlwm.

7. Muaj kev nyab xeeb rautus neeg ua haujlwm.

Nrog ntau yam kev ceeb toom kev nyab xeeb, lub vuam cov lus qhia tsuas yog siv tau thaum lub qhov hloov pauv tau kov thaum nws kov cov hlau, thiab lub teeb yuav raug kaw tom qab lub tshuab ua haujlwm raug tshem tawm, thiab qhov kov hloov pauv tau ntsuas lub cev kub.Kev nyab xeeb yog siab los xyuas kom muaj kev nyab xeeb ntawm tus neeg teb xov tooj thaum ua haujlwm.

8. Txuag nqi zog.

Piv nrog arc vuam, tus nqi ua haujlwm tuaj yeem txo qis li 30%.Kev ua haujlwm yog yooj yim, yooj yim kawm, thiab pib sai.Cov txheej txheem thev naus laus zis ntawm cov neeg ua haujlwm tsis siab.Cov neeg ua haujlwm ib txwm tuaj yeem nqa lawv cov haujlwm tom qab kev cob qhia luv luv, uas tuaj yeem ua tiav cov txiaj ntsig zoo vuam zoo.

9. Yooj yim hloov los ntawm cov txheej txheem vuam ib txwm siv rau fiber ntau laser vuam.

Koj tuaj yeem kawm paub siv Fortune Laser fiber ntau laser vuam tshuab li ntawm ob peb teev, thiab tsis mob taub hau mus nrhiav cov kws tshaj lij vuam, tsis muaj kev txhawj xeeb txog lub sijhawm xa khoom nruj.Dab tsi ntxiv, nrog cov thev naus laus zis tshiab thiab kev nqis peev no, koj yuav ua ntej ntawm kev ua lag luam thiab tuav cov nyiaj tau los ntau dua li cov txheej txheem vuam ib txwm.

Daim ntawv thov teb ntawm Handheld Laser Vuam Tshuab

Lub handheld laser welder yog tsuas yog rau cov ntawv loj thiab nruab nrab ntawm cov ntawv hlau, cov txee, chassis, aluminium alloy qhov rooj thiab qhov rais thav ntawv, stainless hlau ntxhua khaub ncaws thiab lwm yam haujlwm loj, xws li lub kaum sab xis sab xis, sab xis sab xis, tiaj tus vuam vuam. , qhov chaw me me thaum tshav kub kub cuam tshuam thaum vuam, me me deformation, thiab vuam qhov tob loj, muaj zog vuam.

Fortune Laser handheld laser vuam tshuab yog dav siv nyob rau hauv cov txheej txheem nyuaj thiab tsis sib xws ntawm kev lag luam hauv chav ua noj thiab chav dej, kev lag luam hauv tsev, kev lag luam tshaj tawm, kev lag luam pwm, kev lag luam stainless hlau khoom, stainless hlau engineering kev lag luam, qhov rooj thiab qhov rais kev lag luam, kev lag luam xuas tes ua. , kev lag luam khoom siv hauv tsev, rooj tog kev lag luam, kev lag luam tsheb, thiab lwm yam.

Kev sib piv ntawm Handheld Laser Vuam Tshuab thiab Argon Arc Vuam

1. Kev sib piv kev siv hluav taws xob:Piv nrog rau cov tsoos arc vuam, lub tes tuav laser vuam tshuab txuag tau li ntawm 80% mus rau 90% ntawm hluav taws xob, thiab cov nqi ua haujlwm tuaj yeem txo los ntawm 30%.

2. Kev sib piv cov nyhuv vuam:laser tes tuav welding tuaj yeem ua tiav cov hlau tsis sib xws thiab cov hlau tsis sib xws.Qhov ceev yog ceev, qhov deformation yog me me, thiab qhov kub ntawm qhov cuam tshuam yog me me.Weld seam yog zoo nkauj, du, tsis muaj / tsawg porosity, thiab tsis muaj kuab paug.Lub handheld laser vuam tshuab yuav siv tau rau me me qhib qhov chaw thiab precision vuam.

3. Kev sib piv cov txheej txheem tom qab:Cov khoom siv hluav taws xob tsawg thaum lub sij hawm siv lub tshuab laser vuam, me me deformation ntawm lub workpiece, zoo nkauj vuam nto tuaj yeem tau txais, tsis muaj lossis tsuas yog kev kho yooj yim (nyob ntawm seb qhov yuav tsum tau ua ntawm vuam nto nyhuv).Lub handheld laser vuam tshuab tuaj yeem txo cov nqi zog ntawm cov txheej txheem polishing loj thiab qib.

| Hom | Argon arc vuam | YAG welding | HandheldLaservuam | |

| Vuam zoo | Kub input | Loj | Me me | Me me |

|

| Workpiece deformation / undercut | Loj | Me me | Me me |

|

| Weld txoj kev | Ntses-scale qauv | Ntses-scale qauv | du |

|

| Kev ua haujlwm tom ntej | Polish | Polish | Tsis muaj |

| Siv kev ua haujlwm | Vuam ceev | qeeb | Nruab nrab | Ceev ceev |

|

| Kev ua haujlwm nyuaj | Nyuaj | Yooj yim | Yooj yim |

| Kev tiv thaiv ib puag ncig thiab kev nyab xeeb | Ib puag ncig muaj kuab paug | Loj | Me me | Me me |

|

| Lub cev raug mob | Loj | Me me | Me me |

| Welder nqi | Cov khoom siv | Vuam pas nrig | Laser siv lead ua, xenon teeb | Tsis xav tau |

|

| Kev siv hluav taws xob | Me me | Loj | Me me |

| Cov khoom siv hauv pem teb | Me me | Loj | Me me | |