Fortune Laser Handheld Fiber Laser Welding Machine

Fortune Laser Handheld Fiber Laser Welding Machine

Fortune Laser Handheld Laser Welder Technical Amapharamitha

| Imodeli | I-FL-HW1000 | I-FL-HW1500 | I-FL-HW2000 |

| Uhlobo lweLaser | I-1070nm Fiber Laser | ||

| Amandla eLaser Okuzisholo | 1000W | 1500W | 2000W |

| Uhlelo Lokupholisa | Ukupholisa Amanzi | ||

| Indlela yokusebenza | Okuqhubekayo / Ukuguquguquka | ||

| Ububanzi besivinini se-welder | 0~120 mm/s | ||

| I-Focal Spot Diameter | 0.5mm | ||

| Ibanga lokushisa elizungezile | 15 ~ 35 ℃ | ||

| Ibanga lokuswakama kwemvelo | <70% ngaphandle kwe-condensation | ||

| Welding ukujiya | 0.5-1.5mm | 0.5-2mm | 0.5-3mm |

| Izidingo zegebe lokushisela | ≤1.2mm | ||

| I-Voltage yokusebenza | I-AC 220V/50HZ 60HZ/ 380V±5V 50HZ 60HZ 60A | ||

| Ubukhulu beKhabhinethi | 120*60*120cm | ||

| I-Wood Package Dimension | 154*79*137cm | ||

| Isisindo | 285KG | ||

| Ubude befayibha | I-10M ejwayelekile, ubude obude obenziwe ngezifiso buyi-15M | ||

| Isicelo | Ukushisela nokulungisa insimbi engagqwali, i-carbon steel, i-aluminium alloy. | ||

Ephathwayo Handheld Laser Welder for Izinsimbi

| Okubalulekile | Amandla okukhipha (W) | Ukungena okuphezulu (mm) |

| Insimbi engagqwali | 1000 | 0.5-3 |

| Insimbi engagqwali | 1500 | 0.5-4 |

| Insimbi engagqwali | 2000 | 0.5-5 |

| Insimbi ye-carbon | 1000 | 0.5-2.5 |

| Insimbi ye-carbon | 1500 | 0.5-3.5 |

| Insimbi ye-carbon | 2000 | 0.5-4.5 |

| Ingxube ye-aluminium | 1000 | 0.5-2.5 |

| Ingxube ye-aluminium | 1500 | 0.5-3 |

| Ingxube ye-aluminium | 2000 | 0.5-4 |

| Ishidi elinothayela | 1000 | 0.5-1.2 |

| Ishidi elinothayela | 1500 | 0.5-1.8 |

| Ishidi elinothayela | 2000 | 0.5-2.5 |

Imibala Emithathu Yezinketho Zakho

Izinzuzo Handheld Laser Welding Machine

1. Ibanga elibanzi lokushisela:

Ikhanda lokushisela eliphathwa ngesandla lifakwe i-fiber optical yasekuqaleni engu-10M (ubude obude obenziwe ngokwezifiso buyi-15M), obunqoba ukulinganiselwa kwendawo yebhentshi lokusebenzela, futhi ingashiselwa ngaphandle kanye nokushisela ibanga elide;

2. Kulula futhi kuyavumelana nezimo ukusebenzisa:

I-laser welding ebanjwa ngesandla ifakwe ama-pulleys anyakazayo, okunethezeka ukubamba, futhi ingalungisa isiteshi nganoma yisiphi isikhathi, ngaphandle kwesiteshi esigxilile, esikhululekile futhi esivumelana nezimo, futhi sifanele izimo ezihlukahlukene zendawo yokusebenza.

3. Izindlela zokushisela eziningi:

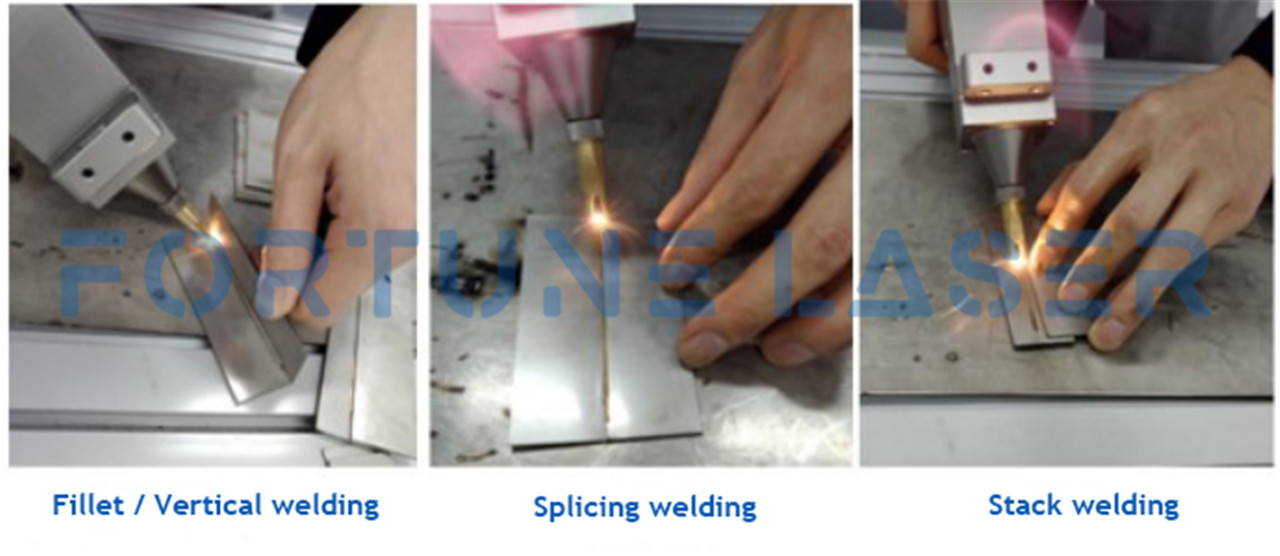

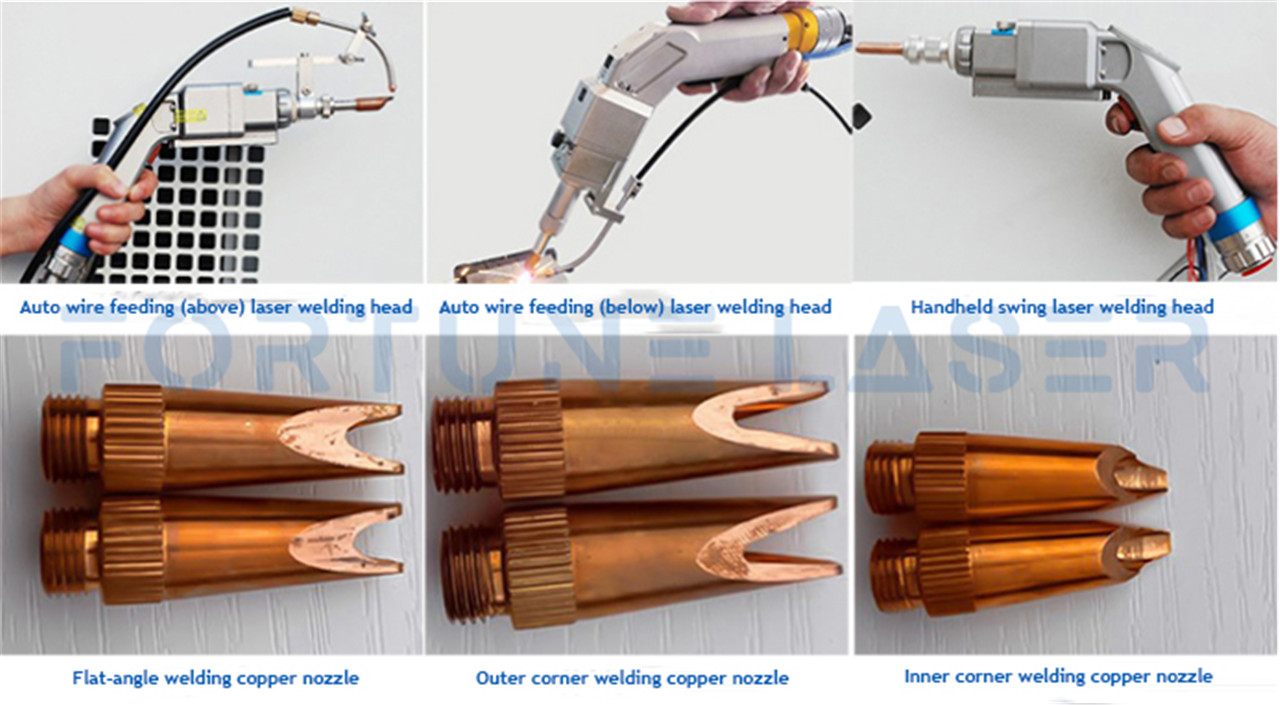

I-Welding kunoma iyiphi i-engeli ingabonakala: i-welding overlap, i-butt welding, i-welding eqondile, i-flat fillet welding, i-fillet ye-internal fillet, i-fillet yangaphandle, njll. Bona ukushisela kunoma iyiphi i-engeli. Ngaphezu kwalokho, ingakwazi futhi ukuqedela ukusika, i-welding kanye nokusika kungashintshwa ngokukhululekile, vele uguqule i-nozzle ye-welding yethusi ku-nozzle yethusi yokusika, elula kakhulu.

4. Umphumela omuhle we-welding:

I-laser ebanjwa ngesandla i-thermal fusion welding. Uma kuqhathaniswa ne-welding yendabuko, i-laser welding inomthamo omkhulu wamandla futhi ingafinyelela imiphumela engcono yokushisela. Indawo yokushisela inethonya elincane elishisayo, akulula ukuyikhubaza, imnyama, futhi inezinsalela emhlane. Ukujula kwe-welding kukhulu, ukuncibilika kwanele, futhi kuqinile futhi kunokwethenjelwa, futhi amandla e-weld afinyelela noma adlula isisekelo sensimbi ngokwayo, esingenakuqinisekiswa ngemishini evamile yokushisela.

5. Umthungo wokushisela awudingi ukupholishwa.

Ngemuva kokushisela okujwayelekile, indawo yokushisela idinga ukupholishwa ukuze kuqinisekiswe ukuthi ibushelelezi futhi ayibi. I-laser welding ebanjwa ngesandla ikhombisa ngokunembile izinzuzo ezengeziwe kumphumela wokucubungula: ukushisela okuqhubekayo, izikali ezibushelelezi futhi ezingenazo izinhlanzi, ezinhle futhi ezingenazo izibazi, nezinqubo ezimbalwa zokupholisha zokulandela.

6. Welding ngeothomathikhi wire feeder.

Ngombono wabantu abaningi, umsebenzi wokushisela "izibuko zesandla sobunxele, intambo yokushisela yesandla sokudla". Kodwa ngomshini ophathwa ngesandla we-laser welding, ukushisela kungaqedwa kalula, okunciphisa izindleko zempahla ekukhiqizeni nasekucubunguleni.

7. Iphephe kakhudlwanaopharetha.

Ngama-alamu amaningi okuphepha, ithiphu yokushisela isebenza kuphela lapho inkinobho ithintwa lapho ithinta insimbi, futhi ukukhanya kukhiywa ngokuzenzakalelayo ngemva kokukhishwa komsebenzi, futhi inkinobho yokuthinta inenzwa yokushisa komzimba. Ukuphepha kuphezulu ukuqinisekisa ukuphepha komsebenzisi ngesikhathi somsebenzi.

8. Yonga izindleko zabasebenzi.

Uma kuqhathaniswa ne-arc welding, izindleko zokucubungula zingancishiswa cishe ngama-30%. Ukusebenza kulula, kulula ukukufunda, futhi kuyashesha ukuqalisa. Umkhawulo wezobuchwepheshe wama-opharetha awuphezulu. Abasebenzi abajwayelekile bangathatha izikhundla zabo ngemuva kokuqeqeshwa okufushane, okungafinyelela kalula imiphumela yekhwalithi ephezulu yokushisela.

9. Kulula ukushintsha kusuka ezindleleni zokushisela zendabuko kuya kwi-fiber laser welding.

Ungafunda ukusebenzisa umshini wokushisela i-Fortune Laser fibre laser emahoreni ambalwa, futhi akukho khanda elibuhlungu ukuze ubheke ochwepheshe bokushisela, ungakhathazeki ngeshejuli yokulethwa eqinile. Ngaphezu kwalokho, ngalobu buchwepheshe obusha kanye nokutshalwa kwezimali, uzoba ngaphambi kwemakethe futhi wamukele amamajini enzuzo engeziwe kunezindlela zokushisela zendabuko.

Izinkambu Zokusebenza Zomshini Wokushisela we-Laser ophethwe ngesandla

I-laser welder ephathwa ngesandla ikakhulukazi eyensimbi yeshidi elikhulu naphakathi, amakhabethe, i-chassis, i-aluminium alloy door kanye namafreyimu amafasitela, izitsha zokugeza zensimbi ezingenasici kanye nezinye izingcezu ezinkulu zokusebenza, njenge-angle yangaphakathi yesokudla, i-angle yangaphandle yesokudla, i-weld weld flat, indawo encane ethinteke ukushisa ngesikhathi sokushisela, ukuguqulwa okuncane, nokujula kwe-welding Okukhulu, okuqinile.

Imishini yokushisela i-laser ye-Fortune Laser isetshenziswa kabanzi kuzinqubo zokushisela eziyinkimbinkimbi nezingajwayelekile zembonini yekhishi neyokugeza, imboni yemishini yasendlini, imboni yokukhangisa, imboni yokubumba, imboni yemikhiqizo yensimbi engagqwali, imboni yobunjiniyela bensimbi, iminyango namafasitela embonini, imboni yezandla, imboni yempahla yasendlini, imboni yefenisha, izingxenye zezimoto, njll.

Ukuqhathaniswa kwe-Handheld Laser Welding Machine kanye ne-Argon Arc Welding

1. Ukuqhathanisa ukusetshenziswa kwamandla:Uma kuqhathaniswa nokushisela kwe-arc yendabuko, umshini wokushisela we-laser ophathwa ngesandla wonga cishe u-80% kuya ku-90% wamandla kagesi, futhi izindleko zokucubungula zingancishiswa cishe ngama-30%.

2. Ukuqhathanisa umphumela we-Welding:i-laser ephathwa ngesandla i-welding ingaqedela insimbi engafani kanye nokushisela kwensimbi okungafani. Ijubane liyashesha, i-deformation incane, futhi indawo ethinteke ukushisa incane. I-weld seam yinhle, ibushelelezi, ayinazo/i-porosity encane, futhi akukho ukungcola. Umshini wokushisela we-laser ophathwa ngesandla ungasetshenziselwa izingxenye ezincane ezivulekile kanye nokushisela okunembayo.

3. Ukuqhathanisa inqubo yokulandelela:okokufaka okushisa okuphansi ngesikhathi sokushiswa kwe-laser ephathwa ngesandla, ukuguqulwa okuncane kwe-workpiece, indawo enhle ye-welding ingatholakala, akukho noma ukwelashwa okulula kuphela (kuye ngokuthi izidingo zomphumela we-welding surface). Umshini wokushisela we-laser ophathwa ngesandla unganciphisa kakhulu izindleko zabasebenzi zenqubo enkulu yokupholisha nokubeka izinga.

| Uhlobo | I-Argon arc welding | Ukushisa kwe-YAG | Uphethe ngesandlaI-Laserukushisela | |

| Ikhwalithi yokushisela | Okokufaka kokushisa | Okukhulu | Encane | Encane |

|

| I-deformation/undercut | Okukhulu | Encane | Encane |

|

| Ukwakhiwa kwe-weld | Iphethini yesikali sezinhlanzi | Iphethini yesikali sezinhlanzi | Bushelelezi |

|

| Ukucubungula okulandelayo | IsiPolish | IsiPolish | Lutho |

| Sebenzisa ukusebenza | Isivinini sokushisela | Kancane | Maphakathi | Ngokushesha |

|

| Ubunzima bokusebenza | Kunzima | Kulula | Kulula |

| Ukuvikelwa kwemvelo nokuphepha | Ukungcoliswa kwemvelo | Okukhulu | Encane | Encane |

|

| Ukulimala komzimba | Okukhulu | Encane | Encane |

| Izindleko zokushisela | Izinto ezisetshenziswayo | Induku yokushisela | I-laser crystal, isibani se-xenon | Asikho isidingo |

|

| Ukusetshenziswa kwamandla | Encane | Okukhulu | Encane |

| Indawo yaphansi yezisetshenziswa | Encane | Okukhulu | Encane | |