As they say, preparation is the key to success. The same goes for laser cutting machine maintenance. A well-maintained machine not only ensures smooth production, but also prolongs its lifespan. A maintenance schedule including daily, weekly and monthly maintenance must be followed. Here are three basic maintenance precautions you must keep in mind.

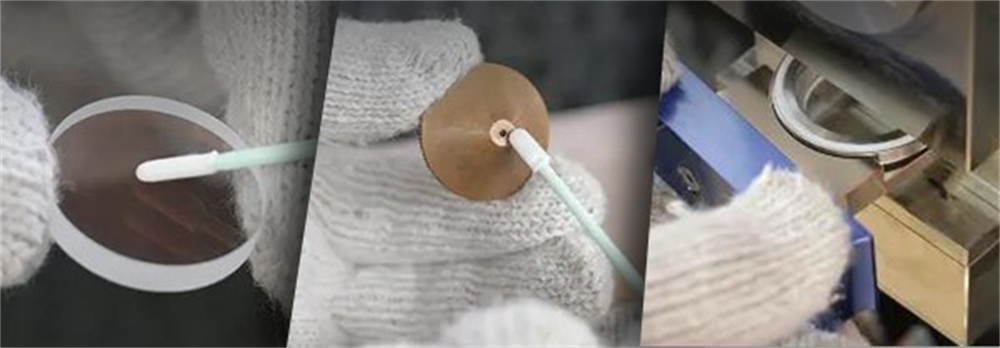

The first thing to remember is routine maintenance. It involves checking that the protective lenses are clean and free from contamination. If not, clean with a soft cloth and make sure no debris remains. It is essential to ensure that the lens is not damaged, scratched or dirty, as it ensures that the laser beam is directed accurately.

Before starting the laser cutting machine, check whether the nozzle is damaged or blocked. If there is any problem, it should be replaced in time, and check whether the protective gas pressure and margin are qualified. A test is recommended to check gas pressure and flow.

Precautions for weekly maintenance: Before starting the laser cutting machine, check whether the water volume of the chiller is above the water level. If not, add distilled water or pure water to adjust to the required water level. The chiller is responsible for regulating the temperature of the laser tube, which plays a vital role in the performance of the machine.

To ensure the longevity of the machine, check the laser tube for any signs of damage. It must be replaced promptly and without delay. In addition, use a soft brush to clean the dust inside the machine. Keep the machine dry and away from moisture.

Monthly maintenance revolves around checking the lubrication of the rails and screws. Make sure the lubricant is clean and not clogged. The rails and screws need to be properly aligned to ensure the accuracy of the laser beam. Disassemble the machine and inspect each component for any potential damage.

In the end, it goes without saying that if any replacements are required, you should only use high-quality parts for them. Skipping quality can end up costing you more in the long run. Working with expert technicians and engineers can ensure a seamless and error-free maintenance process.

To sum up, laser cutting machine maintenance is divided into daily maintenance, weekly maintenance and monthly maintenance. Routine maintenance includes making sure the protective lens is clean and free from contamination, checking the nozzle and shielding gas pressure. Weekly maintenance includes checking the water volume of the chiller, making sure the laser tube is not damaged, and cleaning the inside of the machine for dust. Monthly maintenance includes checking guide rail and screw lubrication and dismantling each part to check for damage. Working with expert technicians is essential to ensure seamless maintenance and the use of high-quality parts. By following these three maintenance precautions, you can ensure your laser cutting machine will perform flawlessly for years to come.

If you want to learn more about laser cutting, or want to buy the best laser cutting machine for you, please leave a message on our website and email us directly!

Post time: Jun-03-2023