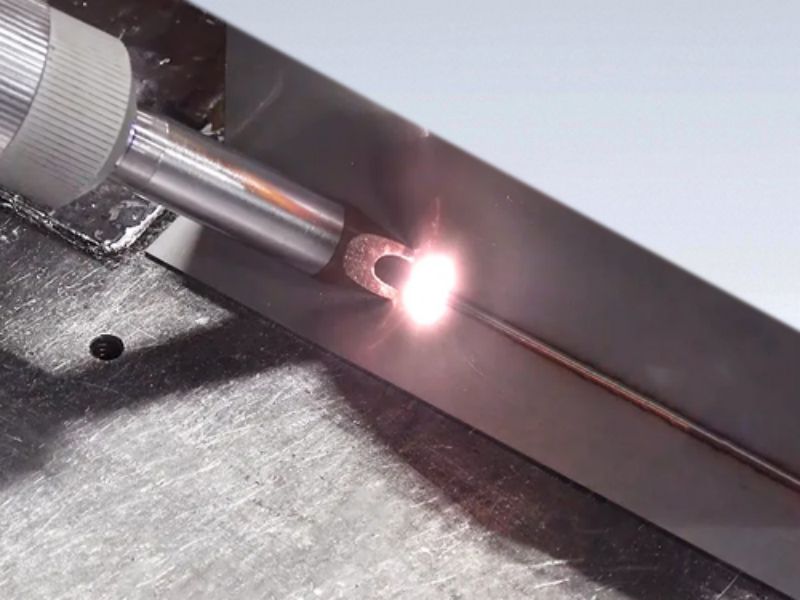

When it comes to laser welding machines, there are many types on the market. Among them, two popular options are water-cooled handheld laser welding machines and air-cooled handheld laser welding machines. The two machines differ not only in their cooling methods, but also in several other ways. In this article, we will explore the differences between these two types of welding machines, how they are cooled, and the corresponding configuration differences.

Let’s first delve into the cooling methods employed by these machines. Water-cooled handheld laser welding machines, as the name suggests, are equipped with a water tank for cooling purposes. On the other hand, air-cooled handheld laser welding machines do not require a water tank. Instead, it uses a fan to direct air to the welding head to dissipate heat. This difference in cooling methods results in significant differences in aspects such as appearance and volume.

One notable difference is the size and weight of these machines. Since there is no water tank, air-cooled handheld laser welding machines are smaller and lighter than water-cooled handheld laser welding machines. Many users find this advantageous because it can be easily operated with both hands. The compact size makes movement very convenient, especially in welding scenarios where frequent movement of equipment is required. Water-cooled handheld laser welding machines, on the other hand, although larger and heavier, usually have swivel wheels on the bottom. This feature makes it easier to operate and transport from one place to another.

Another important aspect to consider is the installation process. Since water-cooled handheld laser welding machines require a water tank, their installation is more complicated than air-cooled ones. The water tank needs to be connected and properly integrated into the overall system, which adds an extra step to the installation process. In contrast, air-cooled handheld laser welding machines do not require the installation of a water tank, simplifying the setup process. This makes air-cooled machines a more convenient option for users who prioritize ease and efficiency of the welding process.

Maintenance is another difference between these two types of welders. Water-cooled handheld laser welding machines require regular monitoring and maintenance of the water tank. This includes regular cleaning and water changes to ensure optimal performance. In contrast, air-cooled handheld laser welders require no water-related maintenance. The only requirement is to keep the fan and air ducts clean to ensure proper cooling. This ease of maintenance makes air-cooled machines a more attractive option for those who prefer a worry-free machine.

A key factor that cannot be ignored is the effectiveness of the cooling method. The water-cooled handheld laser welding machine comes with a water tank that provides efficient and effective cooling. Water has a high specific heat capacity, which means it can absorb a large amount of heat before its temperature rises significantly. This allows the machine to work continuously without overheating. On the other hand, air-cooled handheld laser welding machines rely solely on fans for heat dissipation. While effective, the cooling provided by a fan may not be as effective as a water cooler. This may result in minor limitations such as reduced continuous operation time due to potential overheating.

To sum up, the difference between two small handheld laser welding machines with different cooling methods lies in the differences in the cooling process itself and the corresponding configuration. Water-cooled handheld laser welding machines require a water tank for cooling, while air-cooled types use fans. This fundamental difference affects several aspects, including size, weight, installation process, maintenance requirements and cooling efficiency. By understanding these differences, users can make informed decisions based on their specific welding needs and priorities.

Post time: Oct-09-2023