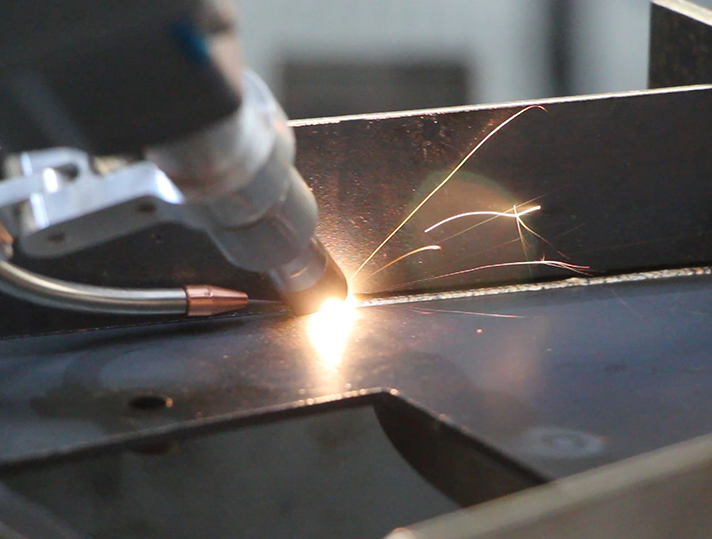

Handheld laser welding machines are popular in various industries due to their versatility and efficiency. In addition to their primary welding capabilities, these machines also offer cutting capabilities, which adds to their usefulness. In this article, we’ll explore a 3-in-1 handheld laser welding machine and learn how to effectively utilize its cutting capabilities.

The welding heads of handheld laser welding machines are usually multi-functional and provide more than just welding functions. In addition to welding, they can also be used for cutting and cleaning purposes. This versatility makes handheld laser welding machines the first choice in many industries. The ability to perform multiple tasks with one machine not only saves time but also increases overall productivity.

To use the cutting function of the handheld laser welding machine, the copper nozzle of the welding head must be replaced. The welding heads of these machines are usually equipped with welding copper nozzles. However, to take advantage of the cutting function, the soldering copper nozzle needs to be replaced with a cutting copper nozzle. This simple step allows users to seamlessly switch between welding and cutting operations according to their requirements.

After replacing the copper nozzle, the next step is to set the cutting parameters on the operation panel. Unlike welding, which requires specific settings, cutting involves a different set of parameters. These parameters determine the speed, depth and precision of the cutting process. By entering the correct values on the operator panel, the user can ensure optimal cutting performance.

Before starting the cutting process, it is crucial to take personal protective measures. This includes wearing goggles, gloves, and other necessary gear to ensure safety when operating a handheld laser welder. Also, never touch the material directly after cutting as it may be hot and may cause burns. Following these precautions will help prevent any potential accidents and injuries.

The cutting capabilities of handheld laser welding machines are very beneficial to various industries. It can cut a variety of materials with precision and efficiency, including metal, plastic. Whether crafting intricate designs or making precise cuts in industrial applications, the cutting capabilities of handheld laser welders offer unparalleled versatility.

In addition to cutting capabilities, handheld laser welding machines also excel in welding tasks. The flexibility and precision these machines offer make them highly sought after. Whether in the automotive, aerospace industries, handheld laser welding machines deliver superior results.

All in all, the 3-in-1 handheld laser welding machine is a game changer for various industries. With its cutting capabilities, this machine enables users to make precise and efficient cuts on a variety of materials. By replacing the copper nozzle, setting cutting parameters, and prioritizing personal protection, users can effectively and safely utilize the cutting capabilities of the handheld laser welding machine. Additionally, the welding and cutting capabilities of these machines make them indispensable tools for meeting the diverse needs of various industries. So, if you are looking for a versatile and efficient welding solution, consider investing in a handheld laser welding machine with cutting capabilities.

Post time: Sep-27-2023