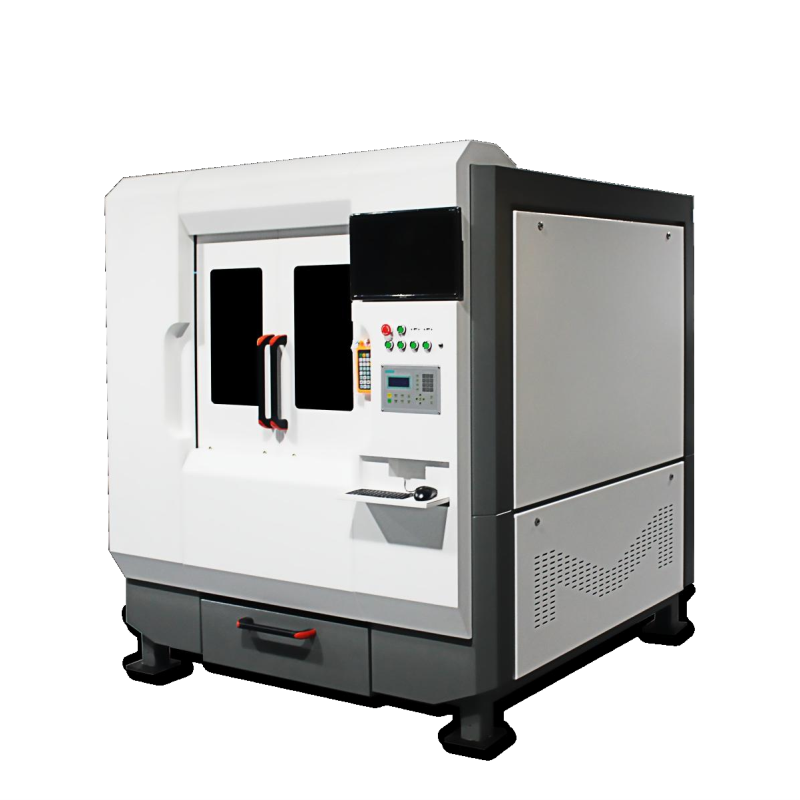

As the temperature rises in summer, do a good job in the maintenance of the laser cutting machine to avoid mechanical failure. Laser cutting machines are prone to problems due to high temperature in summer. In this article, we will discuss the reasons why laser cutting machines have problems in summer and how to maintain them in high temperature. Additionally, we'll look at the skills needed to keep laser cutters safe from high temperatures.

Heavy rain in summer and high humidity in the equipment production environment can cause equipment to rust and corrode. Such a humid environment can also cause a short circuit. In order to avoid these problems, it is necessary to maintain the cooling system and cooling water. Also, rail protection, cleaning and circuit maintenance are important to avoid condensation.

Cooling system and cooling water play a vital role in the maintenance of laser cutting machine in high temperature environment. The temperature of the cooling water must be kept at an appropriate level, and the water quality must be clean. Cooling towers should be inspected for scale and algae growth, which can cause pipe blockages. The water should be changed frequently to prevent impurities from entering the machine and causing corrosion.

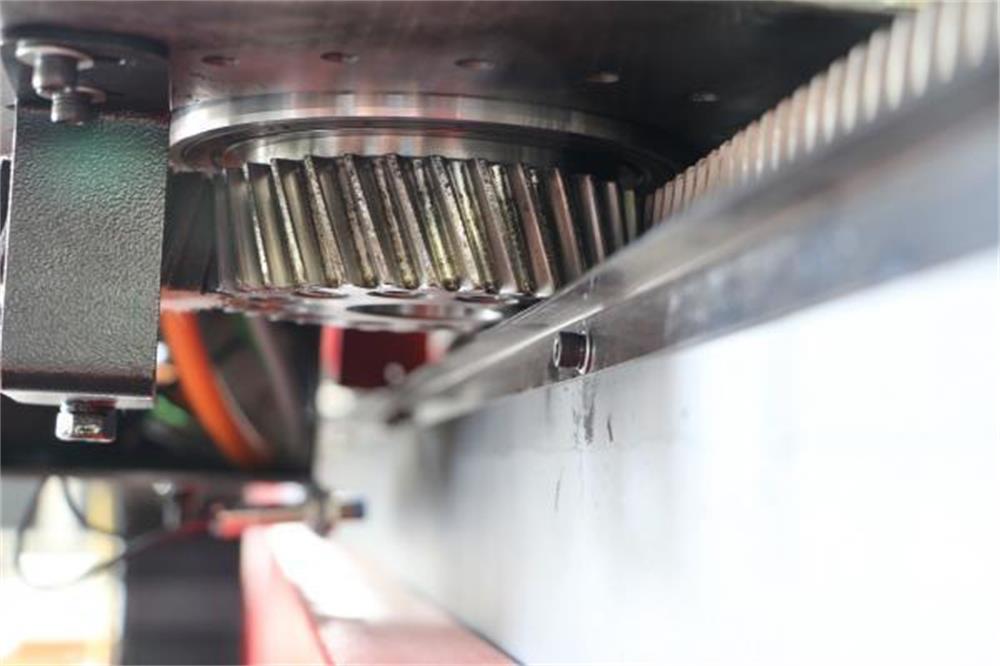

Regular cleaning of your laser cutting machine is a must to ensure its long-term performance. Rails should be inspected frequently to ensure they are running smoothly and to prevent corrosion. Additionally, any dust and debris on the laser cutter body must be removed to prevent damage from overheating.

Circuit maintenance is another important aspect of maintaining your laser cutting machine during the summer. Circuits should be checked frequently to ensure there are no signs of rust or corrosion. The circuit should be cleaned to remove any debris or dust. The machine should avoid liquid infiltration and condensation to prevent circuit damage.

In addition to these maintenance measures, there are a few tricks you can use to avoid high temperatures on your laser cutter. One of those skills is using cooling fans to circulate air inside the machine. This helps avoid heat build-up in critical components and keeps the machine running at its optimum temperature. Also, it is important to ensure that the environment in which the machine is stored is properly ventilated.

Another skill is the use of thermal insulation to prevent heat loss and maintain an optimal temperature for components inside the laser cutter. These materials should be applied to critical components such as laser heads, cutting tables and power supply units.

To sum up, the summer laser cutting machine is prone to problems due to high temperature. Laser cutting machines must be maintained at high temperatures to ensure their long-term performance. Maintenance of the cooling system and cooling water, rail protection, cleaning, circuit maintenance, and the use of certain skills to avoid high temperatures are essential. Proper maintenance and skilled use can help prevent the machine from shutting down or experiencing other mechanical failures in the future.

If you want to learn more about laser cutting, or want to buy the best laser cutting machine for you, please leave a message on our website and email us directly!

Post time: Jun-03-2023