In the industrial cutting process, laser cutting machines have become an indispensable part of various industries. These machines offer precision and efficiency, making them highly sought after by companies requiring precise cuts. However, choosing the right laser cutter for your business can be a daunting task. With so many options on the market, several factors must be considered before making a decision. This article will guide you through the process of selecting the most suitable laser cutting machine for your company.

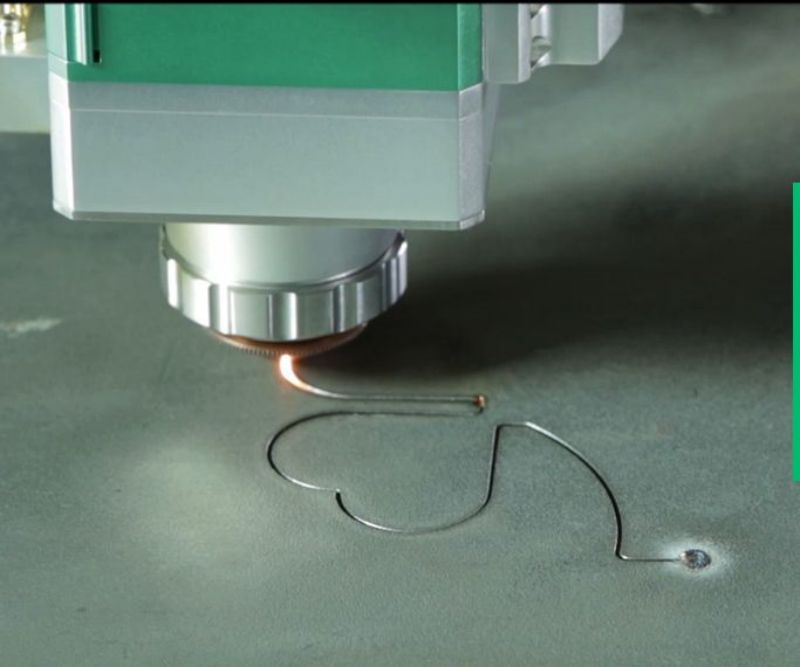

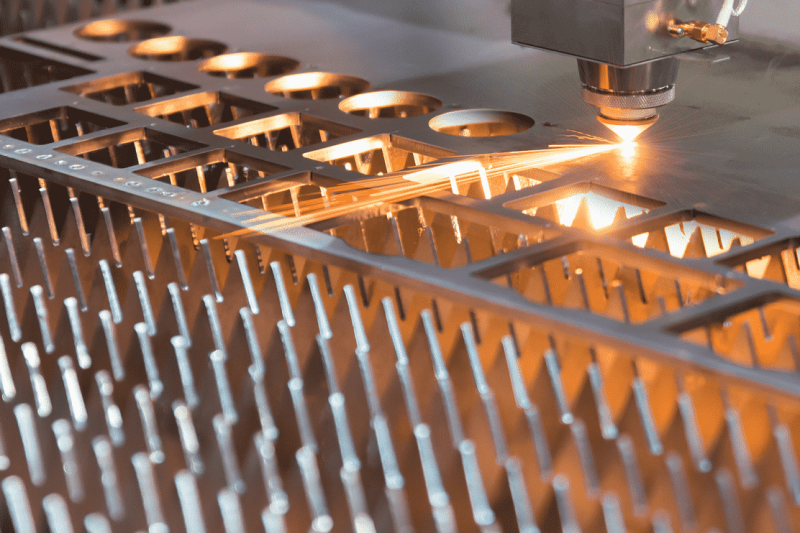

The first step in choosing a laser cutting machine is to determine the cutting material and production parameters required for the manufacturing process. Laser cutting machines can be used to cut sheets, plates, profiles or panels made of different materials such as metal, plastic or composite materials. Each material has its specific cutting requirements, and understanding these parameters will help you identify a machine that can effectively meet your needs.

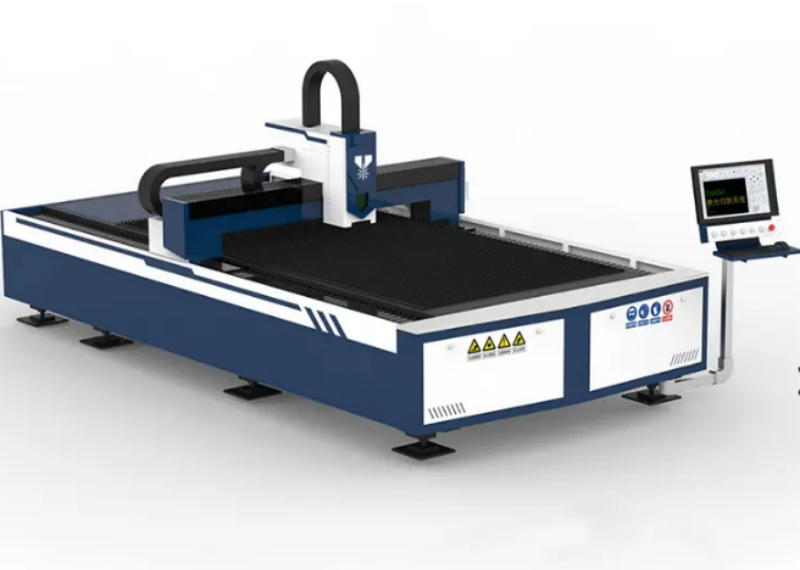

Another key aspect to consider is the overall quality of the laser cutter. The market is flooded with various manufacturers, each claiming to offer the highest quality machines. However, researching and comparing different brands is crucial to ensure that the machine you invest in is built for durability, precision and reliability. Reading customer reviews, checking a manufacturer’s reputation, and considering a machine’s features can help you make an informed decision.

The market share of laser cutting machines is also an important factor to consider. A high market share of a machine shows that the machine is welcomed and trusted by customers. This assures you that the machine has been tested and approved by industry professionals, increasing your confidence in its performance and reliability.

After-sales service is another important consideration when purchasing a laser cutting machine. Even the highest quality machines can experience problems or require maintenance. Therefore, it is crucial to choose a manufacturer that provides high-quality after-sales service, including technical support, spare parts supply and timely assistance. This ensures that your machinery is well maintained and any issues are resolved quickly, minimizing downtime and maximizing productivity.

To determine the best laser cutting machine for your company, it is important to understand the range of production, materials to be processed and thicknesses to cut required for your manufacturing process. Each machine has its own limitations in terms of size, cutting capacity and power, and determining your specific needs will help narrow down your options. On-site professionals can conduct on-site simulations or provide tailor-made solutions based on your manufacturing needs, enabling you to choose the correct model, format and quantity of equipment to purchase.

In conclusion, choosing the right laser cutter for your business requires careful consideration of various factors. Analyzing cutting material and production parameters, assessing the overall quality and market share of a machine, and assessing after-sales service and support are key steps in making informed decisions. By understanding your company’s specific production scope and processing requirements, you can determine the type, specification and quantity of required equipment. Seek professional help when necessary to ensure you select the best laser cutter for your specific manufacturing needs.

Post time: Jul-22-2023