Fortune Laser Technology Co., Ltd. is a well-known manufacturer of industrial laser equipment, integrating R&D, production, sales and maintenance services. Fortune Laser's consistent delivery of high performance laser cleaning machines has made it one of the fastest growing industrial laser companies on the market. Laser cleaning machines are also known as laser cleaning machines or laser cleaning systems. It utilizes the high energy density of the laser beam to create fine, deep cleaning seams and high cleaning rates.

In addition, the laser cleaning machine is mainly used for metal cleaning, and it can also easily clean dissimilar materials. These machines are gaining popularity in the manufacturing industry due to their superior cleaning capabilities compared to traditional cleaning methods such as blast cleaning, scrub cleaning, and chemical cleaning.

Laser cleaning is a cleaning method that is increasingly popular with industry professionals. One of the main applications of laser cleaning is the removal of paint from various surfaces such as metals, plastics, and even brittle materials such as glass. Laser cleaning uses a high-energy laser beam to evaporate the surface layer of a material, thereby removing unwanted substances. So, how does laser cleaning equipment remove paint? Let's explore.

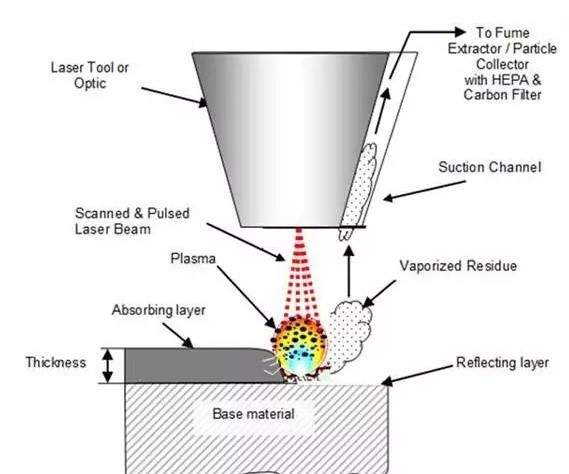

The first step in the laser cleaning process is selecting the correct type of laser for the task. The most common lasers used for paint removal are pulsed fiber lasers and solid-state lasers. This is because these lasers are very efficient and accurate at removing paint without damaging the underlying material.

Once the laser is chosen, the next step is to focus the laser beam onto the painted surface. The laser beam is constantly moved over the surface being cleaned, sending out high-energy pulses that evaporate the paint. The laser-induced vaporization process causes the paint to expand rapidly, creating a shock wave that strips the paint from the surface.

At this point, the paint has been removed from the surface, but residue may still remain. Therefore, to complete the cleaning process, a vacuum or suction device is usually used to clean the surface. This ensures that any remaining particles or debris are removed, leaving a clean surface.

One of the main features of a laser cleaning machine is its ultra-small machine size. This feature sets it apart from other cleaning methods because it is easy to carry and operate. In addition, laser cleaning equipment is backpack-carryable, making it easy for technicians to carry it from one place to another.

In addition, the laser cleaning machine is equipped with a machine safety lock function to ensure the safety of the operator; thus, reducing the possibility of accidents. This capability is critical for industries that handle heavy metals and equipment that may pose a safety risk to operators.

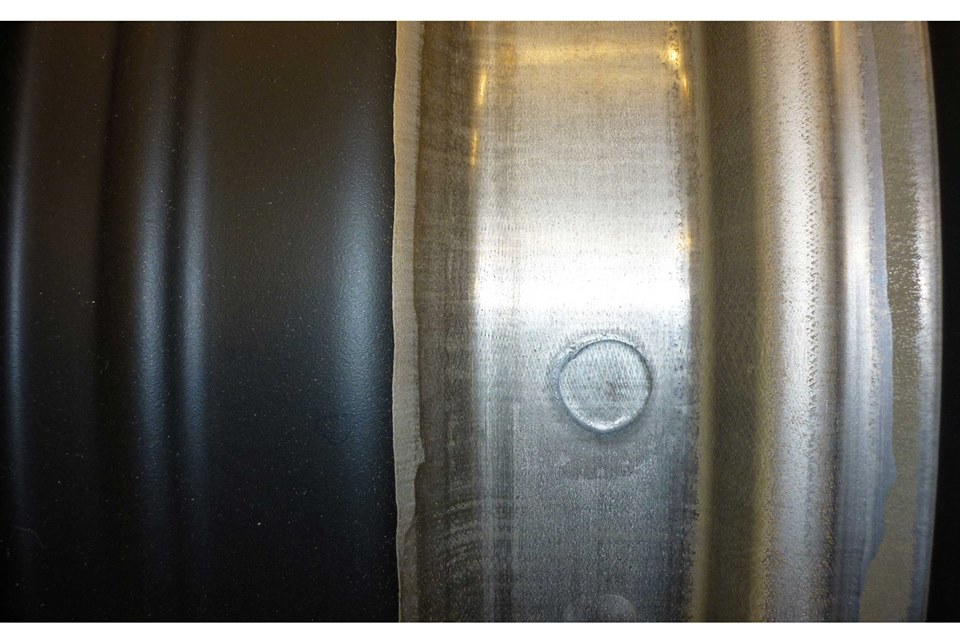

Laser cleaning machines can be used to remove rust, oil and oxide layers from metal surfaces. With these features, laser cleaning equipment is increasingly becoming the first choice for manufacturing. The compact size of the laser cleaning system makes it possible to clean the machine in areas that are difficult to reach with traditional cleaning methods.

In addition, laser cleaners are more effective than abrasive blasting, scrubbing, and chemical cleaning methods. Traditional cleaning methods damage the surfaces being cleaned, generate waste, and require extensive pre- and post-cleaning preparation, taking up valuable time in the manufacturing process.

In conclusion, laser cleaning machines are an efficient and effective industrial cleaning technique that provides optimal cleaning results with minimal waste and disruption to the manufacturing process. With its ultra-small size, portability and safety, operators can use it easily and safely. What's more, the laser cleaning machine has excellent cleaning precision, making it the first choice for the manufacturing industry. Fortune Laser Technology Co., Ltd. prides itself on providing high-performance laser cleaning machines that meet customers' specific needs and requirements. Contact the company today to learn about their range of laser cleaning machines and improve your industrial cleaning process.

If you want to learn more about laser cleaning, or want to buy the best laser cleaning machine for you, please leave a message on our website and email us directly!

Post time: Apr-03-2023