Laser cutting technology has revolutionized the metalworking industry with its exceptional precision and high-quality results. One of the most widely used applications of laser cutting is pipe cutting, which provides a fast and efficient method of forming metal pipes to meet various industrial needs. Although, as the name suggests, laser tube cutting machines are designed specifically for cutting round tubes, this innovative technology is versatile and can be used to cut tubes of different shapes and sizes.

The laser round pipe cutting machine is equipped with advanced functions and cutting modes, which enable it to meet various pipe cutting requirements. By adjusting the cutting control parameters, the machine can meet the diverse needs of the industry and provide high-quality finished products. It is not only suitable for cutting round pipes, but also capable of cutting regular metal pipes. This versatility makes it ideal for a wide variety of applications.

The cutting mode of the laser round tube cutting machine is highly flexible, allowing precise and clean cuts on different types of materials. Whether it is stainless steel, carbon steel, aluminum or any other metal, the machine ensures precise, efficient cuts resulting in smooth edges and minimizing waste. The laser technology used by this machine can easily cut intricate designs and intricate shapes, offering endless possibilities for creativity and customization.

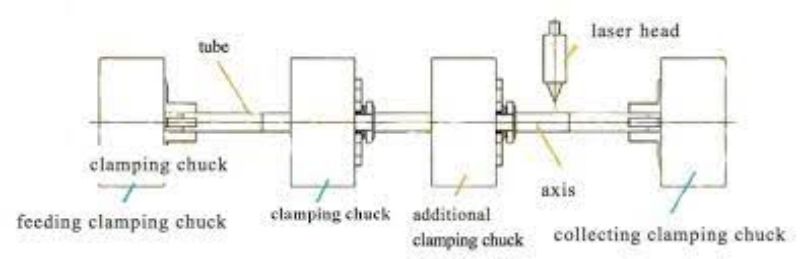

In addition to the cutting function, the laser round tube cutting machine can also be integrated with the robot system to realize the complete automation of processing and production. By matching with corresponding robots, manufacturers can increase productivity and efficiency while reducing labor costs. The machine works seamlessly with a robotic arm that handles the positioning and movement of the pipe, ensuring precise cuts and reducing the risk of errors.

The laser cutting method used by the round tube cutting machine has several advantages over traditional cutting techniques. Unlike traditional methods involving mechanical force or thermal energy, laser cutting uses a focused beam of light to melt or vaporize material. This non-contact cutting method requires no physical contact, reducing the risk of pipe damage or deformation. It also minimizes the creation of the heat-affected zone, resulting in cleaner cuts and less material distortion.

In addition, laser cutting is an efficient process that can significantly reduce production time. With its high-speed cutting capability, the laser round pipe cutting machine can quickly and accurately cut metal pipes of various thicknesses. This allows manufacturers to achieve faster turnaround times and meet production deadlines without compromising the quality of the finished product.

Laser tube cutting machines are not limited to cutting tubes. It is a versatile technique that can form and cut pipes of different shapes and sizes, including square, rectangular, and even irregularly shaped pipes. The machine's adjustable cutting control parameters ensure it can be adapted to the specific requirements of each project, delivering precise cuts regardless of pipe shape.

In summary, the laser round pipe cutting machine is an advanced piece of equipment that provides superior cutting capabilities for a variety of pipe cutting needs. Its flexibility, precision and efficiency make it a valuable asset for industries requiring high quality finished products. The machine is not limited to cutting round tubes, but can also process traditional metal tubes for a wide range of uses. With its ability to integrate with robotic systems, it enables manufacturers to automate processing and production, increasing productivity and reducing labor costs. The laser cutting method employed by this machine ensures clean cuts, minimal material distortion and faster turnaround times. In the ever-growing metalworking industry, the laser tube cutting machine is a symbol of innovation and efficiency.

Post time: Sep-04-2023