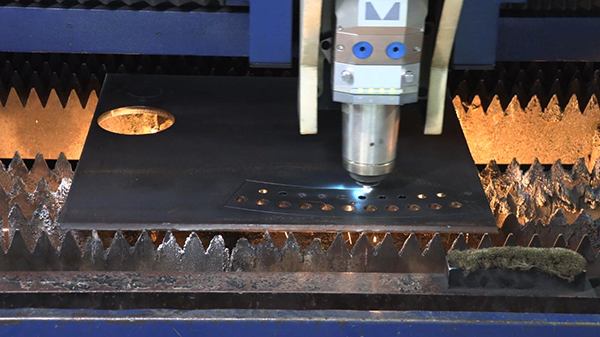

Fiber laser cutting machines have revolutionized industrial manufacturing, and the advent of 10,000 watts of power takes their capabilities to a whole new level. The 10,000-watt fiber laser cutting machine has high stability, compact structure, and fixed optical path. It has many advantages compared with similar products. In this article, we’ll explore the benefits of this cutting-edge technology while delving into its product descriptions.

Compact and efficient

One of the main advantages of the 10,000-watt fiber laser cutting machine is its compact size and energy-efficient operation. The machine is equipped with an imported fiber laser with excellent stability, ensuring precision and accuracy for long-term use. Its small size allows it to blend seamlessly into any workspace, making it ideal for small to medium-sized manufacturing units. Additionally, fixed light paths minimize energy consumption, thereby reducing operating costs and environmental impact.

Minimum optical limitations

Unlike traditional cutting machines, the 10,000-watt fiber laser cutting machine provides an unrestricted light path, allowing greater flexibility and versatility in cutting patterns. This unrestricted optical path ensures minimal fiber transmission losses, resulting in efficient, consistent cutting of a variety of materials. By reducing light energy loss, the machine maximizes the use of laser power, resulting in improved cut quality and faster processing speeds.

Use specialized software to improve accuracy

To fully realize the potential of a 10,000-watt fiber laser cutting machine, professional software must be used to process various graphics and text in a timely manner. With this advanced software, complex designs and complex patterns can be easily transformed into precise cutting paths. The user-friendly interface makes machine operation simple and convenient, reducing the operator's learning curve while maintaining high accuracy. Whether custom products or mass production, the software increases efficiency and precision, allowing manufacturers to meet modern production requirements.

Versatility of application

The high power capacity of the 10,000 watt fiber laser cutting machine enables it to perform a variety of cutting tasks across different industries. From sheet metal fabrication to automotive manufacturing, this machine can easily cut different materials of varying thicknesses. Whether it’s steel, aluminum, or even non-metallic materials like plastic, wood, and composites, the 10,000-watt fiber laser cutting machine delivers consistent, high-quality results. Its adaptability makes it a valuable asset for businesses looking to streamline production processes and diversify product offerings.

Conclusion

All in all, a 10,000-watt fiber laser cutting machine offers many advantages. With its high stability, compact size, low energy consumption and unrestricted optical path, the machine sets higher standards for precision and efficiency in cutting operations. Additionally, the integration of professional software enhances its ability to handle complex designs with ease. When considering manufacturing technology, a 10,000-watt fiber laser cutting machine is a powerful and versatile solution that enables businesses to increase productivity, minimize costs, and deliver quality products in today's competitive market.

Post time: Nov-29-2023