How does laser welding machine work?

As technology advances, traditional cleaning methods are gradually being replaced by innovative and efficient solutions. Among them, laser cleaners have attracted much attention due to their ability to effectively remove contaminants from various surfaces. Pulse and continuous wave (CW) laser cleaners are two popular options on the market. In this blog, we'll take an in-depth look at the features, applications and benefits of pulsed and continuous laser cleaners to help you make an informed decision.

Learn about pulsed laser cleaners

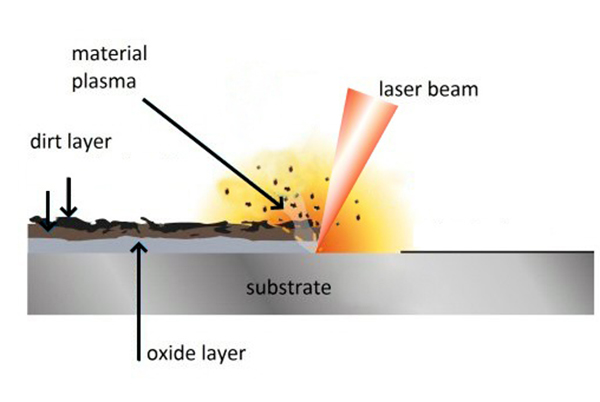

Pulsed laser cleaners, as the name suggests, emit laser pulses in short bursts. These pulses interact with the contaminant surface, resulting in plasma creation, rapid heating and expansion. Eventually, the contaminants are evaporated or pushed out of the surface. This process happens so quickly that the underlying material is not affected.

Applications of Pulse Laser Cleaning Machine

1. Electronics and semiconductor industry: pulsed laser cleaning machines are widely used to remove oxides, paints and other unwanted materials in electronic components and semiconductors. The non-contact nature of the pulsed laser ensures that delicate components are not damaged during the cleaning process.

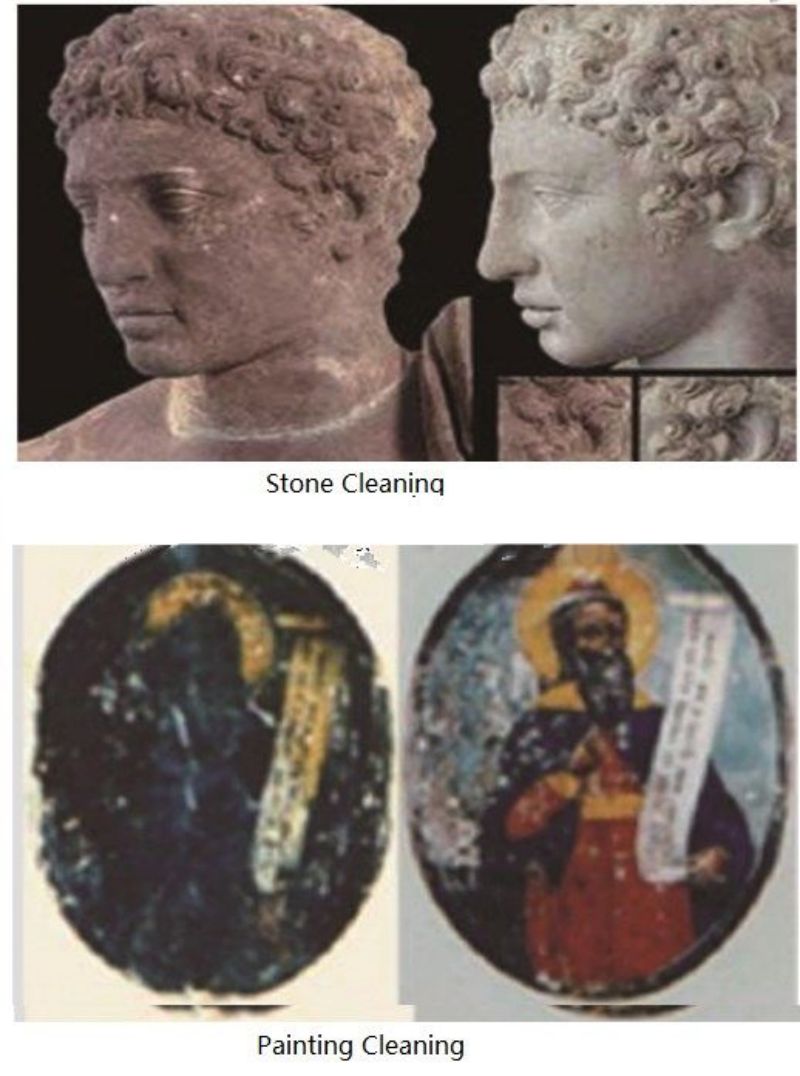

2. Restoration of Historic Artifacts: It is critical to precisely clean delicate artwork or historical artefacts without causing any damage. Pulsed lasers provide gentle and controlled cleaning, making them ideal for restoring valuable cultural heritage.

3. Automobile manufacturing: Pulse laser cleaning machine is used to remove pollutants on the metal surface or painted surface of automobiles. The ability to clean intricate parts and tight spaces makes it very useful in this industry.

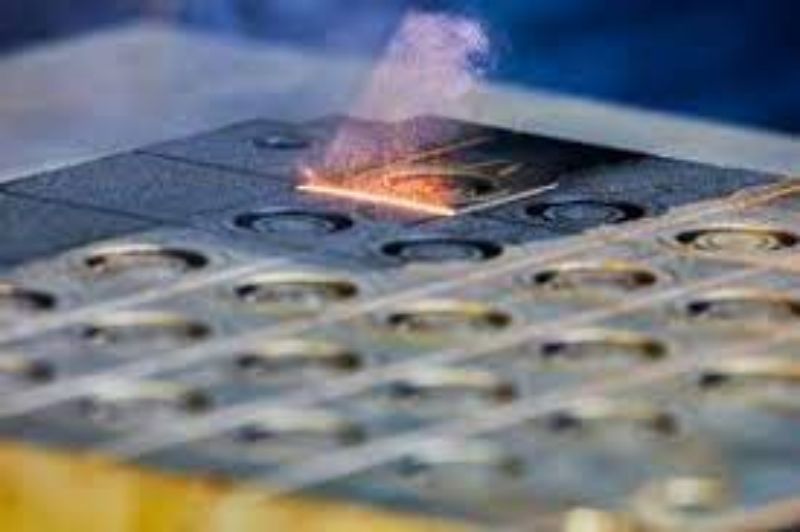

4. Mold cleaning: The pulse cleaning machine can use high-energy laser pulses to quickly shoot down the dirt on the surface of the mold. The cleaning speed is fast and the cleaning time is saved. It can clean the hard-to-reach fine areas without damaging the mold surface and maintain the precision of the mold.

5. Ships, Aerospace: Ships and aerospace equipment are often exposed to harsh environments, resulting in the accumulation of large amounts of dirt and oxides on surfaces. A laser pulse cleaner removes these dirt and oxides quickly and thoroughly, restoring surface cleanliness. It can effectively clean the key parts of the equipment, eliminate pollution and hidden dangers, and improve the reliability and safety of the equipment.

6. Wall cleaning: The laser pulse cleaning machine can quickly and thoroughly clean the stains, oil stains, mildew spots on the wall surface, and remove stains and graffiti after a house fire. The laser energy is highly concentrated, which can quickly remove stubborn dirt and make the wall look brand new. The force and time of the laser beam can be precisely controlled to avoid damage to the wall material and not cause wear and peeling of the wall surface.

Advantages of pulse laser cleaning machine

1. No chemicals or abrasives: Pulse laser cleaning eliminates the use of harsh chemicals or abrasives that can damage the surface being cleaned. This is especially useful when working with sensitive materials.

2. Non-contact cleaning: The non-contact nature of the pulsed laser can prevent scratches or marks on delicate surfaces, ensuring the service life of the object or material being cleaned.

3. Precision and Versatility: Pulsed laser cleaners can be precisely controlled, allowing customized cleaning based on the nature and thickness of the contaminant. Their versatility makes them suitable for a wide variety of industries and applications.

Disadvantages of laser pulse cleaners may include:

1.Cleaning is relatively slow because only short laser pulses are fired for each cleaning.

2.Cleaning effectiveness is limited by the reflective and absorptive capabilities of the material and may not be ideal for some materials.

3.The price is relatively high, and the equipment and maintenance costs of the laser pulse cleaning machine are relatively high.

Discover CW Laser Cleaners

Continuous laser cleaners emit a continuous laser beam instead of pulses. The laser beam is focused on the desired cleaning point and uses thermal energy to steadily remove contaminants. The temperature rise rapidly removes or evaporates the contaminants, while the underlying surface is unaffected.

Application of continuous wave laser cleaning machine

1. Manufacturing and Industrial Cleaning: CW laser cleaners are widely used to maintain industrial equipment, remove rust, or clean large metal surfaces by eliminating organic or inorganic contaminants.

Advantages of CW Laser Cleaning Machine

1. Continuous cleaning process: Unlike pulsed laser cleaners, CW laser cleaners provide continuous cleaning, resulting in faster cleaning cycles, especially for large surfaces or high-volume production lines.

2. Efficient removal of contaminants: CW laser cleaners are good at removing organic matter from surfaces such as oil, grease or biofilm. This makes them essential for industries with strict hygiene requirements.

3. Higher surface energy: After cleaning, the CW laser increases the surface energy of the material, which can enhance subsequent bonding, painting or coating processes.

Disadvantages of laser continuous cleaners may include

1.The cleaning effect may be slightly inferior to laser pulse cleaning machines, because continuous laser cleaning may be difficult to remove some stubborn dirt.

2.Cleaning is relatively fast, but can still be slow compared to other cleaning methods such as spray cleaning. During the cleaning process, more smoke and exhaust gas may be produced, which will have a certain impact on the health of the operator and the environment.

3.The same price is higher, and the equipment and maintenance costs are higher.

Choose the laser cleaner that fits your needs:

Individual users can consider the following factors when choosing laser pulse cleaning machines and laser continuous cleaning machines:

Cleaning needs: First of all, you must clarify your own cleaning needs, understand the types of objects to be cleaned and the types of dirt. If you need to remove stubborn dirt or have high cleaning quality requirements, you can consider a laser pulse cleaning machine. If cleaning speed and efficiency are the main concerns, consider a laser continuous cleaner.

Cleaning effect: The laser pulse cleaning machine can provide higher power density and stronger cleaning ability, and can remove dirt more thoroughly. And laser continuous cleaning machine may have better cleaning effect in some specific occasions. Users can choose the appropriate cleaning effect according to their needs.

Cost considerations: Laser pulse cleaning machines and laser continuous cleaning machines are more expensive, and equipment and maintenance costs are also higher. Individual users can make comprehensive considerations according to their own budget and cleaning needs.

Safety: The laser cleaning machine uses laser technology, which will produce certain laser radiation and smoke. Individual users should consider relevant safety measures when choosing to ensure the safety of themselves and the surrounding environment.

Both pulsed and continuous laser cleaners offer unique advantages, depending on the application. Factors such as surface type, nature of contamination, required precision and productivity should be considered when selecting the appropriate laser cleaner.

Ultimately, it is critical to consult a manufacturer, expert or provider specializing in laser cleaning solutions to determine the option that best suits your specific cleaning needs. By integrating innovative laser cleaning technology, you can achieve efficient, non-destructive and environmentally friendly cleaning in multiple industries.

As technology continues to evolve, pulsed laser cleaners and continuous wave laser cleaners have emerged as breakthrough cleaning solutions. Pulsed lasers are known for their precision and versatility, while continuous wave lasers provide continuous cleaning cycles and efficient contaminant removal. By understanding the features, applications and benefits of each type, you can make informed decisions to optimize your cleaning process and achieve superior results. Harness the power of laser cleaners to revolutionize your cleaning methods and increase productivity across industries.

Post time: Aug-16-2023