How does laser welding machine work?

The laser welding machine uses the huge energy of the laser pulse to heat the material to be processed in a small range, and finally melts it to form a specific molten pool, which can realize spot welding, butt welding, lap welding, sealing welding, etc. Its unique advantages open up a new application field of laser welding, providing precision welding for thin-walled materials and tiny parts.

What is laser welding machine used for?

1. Welding

The main purpose of the laser welding machine is undoubtedly welding. It can not only weld thin-walled metal materials such as stainless steel plates, aluminum plates, and galvanized plates, but also can be used for welding sheet metal parts, such as kitchen utensils. It is suitable for flat, straight, arc and Welding of any shape is widely used in precision machinery, jewelry, electronic components, batteries, watches, communications, handicrafts and other industries. It can complete welding well in various complex environments and has high production efficiency. Compared with traditional argon arc welding and electric welding And other processes have more obvious advantages.

Using a laser welding machine, the weld seam has small width, large depth, small thermal shock area, small deformation, smooth and beautiful weld seam, high welding quality, no air holes, accurate control, stable welding quality, no need for treatment or simple treatment after welding Can.

2. Repair

The use of the laser welding machine is not limited to welding, but also to repair the wear, defect, scratch of the mold, and the sand hole, crack, deformation and other defects of the metal workpiece. The mold will wear out after a long time of use. If it is directly discarded, the loss will be large. The problematic mold can be fully utilized again by repairing the problematic mold through the laser welding machine, especially when repairing the fine surface, avoiding the two problems of thermal strain and post-welding treatment. One process, greatly saving production time and production costs.

What welding process does laser welding machine have?

1. Welding between pieces

Including butt welding, end welding, center penetration fusion welding, and center penetration fusion welding.

2. Wire to wire welding

Including wire-to-wire butt welding, cross welding, parallel lap welding, and T-shaped welding.

3. Welding of metal wire and block components

Laser welding can successfully realize the connection of metal wire and block components, and the size of block components can be arbitrary. Attention should be paid to the geometrical dimensions of the filamentary elements during welding.

4. Welding of different metals

Welding of different types of metals addresses weldability and weldability parameter ranges. Laser welding between different materials is only possible with certain material combinations.

How to choose the right laser source?

Yg laser source:

Sheet metal, gold jewelry links, titanium pacemakers, razor blades for welding with pulsed lasers.

This type of laser prevents the metal from melting or deforming.

For thin and light metals.

CW laser source:

This is more expensive compared to pulsed lasers. It also reduces operating costs.

Most effective on refractory metals.

Recommended for welding thick parts.

It can cause problems if used on metal or parts that are too thin. In this case, the laser can damage, melt or deform the part.

What kinds of welding machines are there in total?

Laser welding machines are also known as laser welding machines and laser welding machines. The specific classifications are as follows:

1. Handheld laser welding machine:

This is probably the most common type of welding equipment on the market. Often used for welding various metal sheets.

2. Laser spot welding machine:

It can be used for gold and silver jewelry, hole filling of electronic components, spot welding blisters, welding inlays, etc.

3. Automatic laser welding machine:

It is suitable for automatic welding of straight lines and circles of metal workpieces, and is often used in industries such as mobile phone batteries, jewelry, electronic components, sensors, clocks and watches, precision machinery, communications, and handicrafts.

4. Laser mold welding machine:

It is mainly used for mold repair in mold manufacturing and molding industries such as mobile phones, digital products, automobiles and motorcycles, and is also mostly used for manual welding.

5. Optical fiber transmission laser welding machine:

For parts that are difficult to access for welding, flexible transmission non-contact welding is implemented, which has greater flexibility. The laser beam can realize time and energy splitting, and can process multiple beams at the same time, which provides conditions for precision welding.

6. Optical fiber galvanometer laser welding machine:

The perfect combination of galvanometer motion system and laser welding system. Effectively save the empty positioning time during single-point welding, and improve the efficiency by 3~5 times compared with the traditional electric workbench

Introduction to specific types of welding machines:

Hand held laser welding machine

The most common laser metal processing equipment on the market is the handheld laser welding machine. In traditional welding equipment, a combination of rich welding experience and technology is basically required to meet daily production, and the speed is slow, and the appearance of welding needs subsequent polishing. Processing is time-consuming and laborious.

Model introduction: Use optical fiber to transmit laser, and focus the laser beam directly on the welding part through a hand-held spray gun. It has the characteristics of high precision, high efficiency and low heat-affected zone, and is suitable for welding small, complicated or hard-to-reach parts.

The main advantage:

1 The operation is simple, no professional welding technology experience is required, and the operation can be started after 2 hours of simple training.

2 The welding speed is super fast, and a handheld laser welder can basically replace the output of 3 to 5 ordinary welders.

3 Welding can be basically free of consumables, saving costs in production.

4 After the welding is completed, the weld seam is bright and clean, and it can basically be done without grinding.

5. The energy of the laser welding machine is concentrated, the range of heat reflection is small, and the product is not easy to deform.

6 The energy of the laser welding machine is concentrated, and the welding strength is very high.

7. The energy and power of the laser welding machine are digitally controlled, which can meet various welding requirements, such as complete penetration, penetration, spot welding and so on.

Applicable materials and industry applications: mainly used in electronic components, auto parts, instruments, precision machinery, communication equipment and other industries stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized sheet, galvanized sheet, copper, etc. Fast welding of various metal materials and welding between certain dissimilar materials.

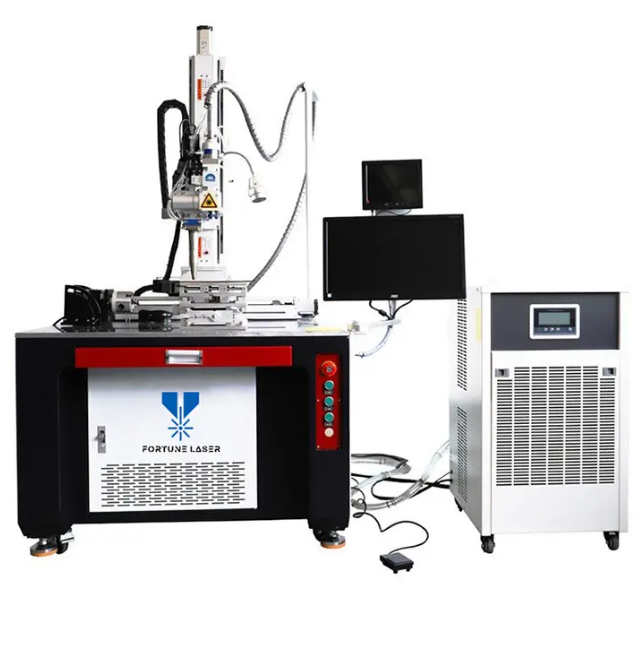

Automatic laser welding machine-two-dimensional automatic laser welding machine

Model Introduction:

The machine adopts double-lamp ceramic concentrating cavity imported from the UK, with powerful power, programmable pulse and intelligent system management. The Z-axis of the workbench can move up and down electrically to focus, and is controlled by an industrial PC. Equipped with standard separate X/Y axis three-dimensional automatic moving table. Another optional rotary fixture (80mm or p 125mm optional) to achieve two-dimensional automatic laser welding. The monitoring system adopts microscope, red light and CCD. Equipped with external water cooling system.

The main advantage:

1. The double-lamp ceramic concentrator cavity imported from the UK is used, which is corrosion-resistant and high-temperature resistant, and the life of the cavity is 8-10 years.

2. The production efficiency is high, the welding speed is fast, and the automatic mass production of the assembly line can be realized.

3. The laser head can be rotated 360°, and the overall optical path can be moved 360° and stretched back and forth.

4. The size of the light spot can be adjusted electrically.

5. The working platform can be electrically moved in three dimensions.

Applicable materials and industry applications:

Suitable for kettles, vacuum cups, stainless steel bowls, sensors, tungsten wires, high-power diodes (transistors), aluminum alloys, laptop casings, mobile phone batteries, door handles, molds, electrical accessories, filters, nozzles, stainless steel products, golf Ball head, zinc alloy crafts and other welding. Weldable graphics include: points, straight lines, circles, squares or any plane graphics drawn by AutoCAD software.

Desktop integrated, separate, mini laser spot welding

Model Introduction:

Laser spot welding machine is mainly used for repairing holes and spot welding blisters of gold and silver jewelry. Laser spot welding is one of the important aspects of the application of laser material processing technology. The spot welding process is of heat conduction type, that is, the laser radiation heats the surface of the workpiece, and the surface heat diffuses to the interior through heat conduction. By controlling the width, energy, peak power and repetition of the laser pulse Parameters such as frequency make the workpiece melt and form a specific molten pool. Due to its unique advantages, it has been successfully applied in gold and silver jewelry processing and welding of micro-small parts.

Model Features:

Fast speed, high efficiency, large depth, small deformation, small heat-affected zone, high welding quality, no pollution of solder joints, high efficiency and environmental protection.

The main advantage:

1. Energy, pulse width, frequency, spot size, etc. can be adjusted within a large range to achieve a variety of welding effects. The parameters are controlled and adjusted in a closed cavity, which is simple and efficient.

2. The ceramic concentrating cavity imported from the United Kingdom is used, which is corrosion-resistant, high-temperature resistant, and has high photoelectric conversion efficiency.

3. Adopt the world's most advanced automatic shading system, which eliminates the irritation to the eyes during working hours.

4. It has the ability to work continuously for 24 hours, the whole machine has stable working performance, and is maintenance-free within 10,000 hours.

5. Humanized design, in line with ergonomics, can work for a long time without fatigue.

Laser Mold Welding Machine

Model Introduction:

The laser mold welding machine is a special model tailored for the mold industry. This machine is specially used to replace the traditional argon arc welding machine for repairing precision molds. The key components of the machine are all imported products. The software operation interface adopts a large-screen liquid crystal display, and the interface is simple and clear, and the operator is easy to learn and use. A variety of pre-stored operation modes can also be programmed by yourself, and the permanent memory function can be applied to various materials.

Model Features:

1. The heat-affected area is small and will not cause deformation of precision molds;

2. The welding depth is large and the welding is firm. Fully melted, leaving no repair traces. There is no depression at the joint between the raised part of the molten pool and the substrate;

3. Low oxidation rate, the workpiece will not change color;

4. There will be no air holes or sand holes after welding;

5. The weld can be processed, especially suitable for mold repairs with polishing requirements;

6. The workpiece can reach 50~60 Rockwell hardness after welding.

Applications:

Mold, precision injection molding, die-casting, stamping, stainless steel and other hard materials such as cracks, chipping, edge grinding machine wear and sealing edge repair, welding; high accuracy, laser welding spot diameter is only 0.2nm~1.5nm; heating area is small, processing The workpiece will not be deformed; it can be etched after welding without affecting the effect.

Optical fiber transmission automatic laser welding machine

Model Introduction:

Optical fiber transmission laser welding machine is a kind of laser welding equipment that couples high-energy laser beam into optical fiber, after long-distance transmission, collimates parallel light through collimating mirror, and performs welding on workpiece. Weld large molds and inaccessible precision parts, and implement flexible transmission non-contact welding, which has greater flexibility. The laser beam can achieve time and energy splitting, and can process multiple beams at the same time, providing more convenient conditions for welding.

Main feature:

1.Optional CCD camera monitoring system, convenient for observation and precise positioning;

2.The energy distribution of welding spot is uniform, and it has the best light spot required for welding characteristics;

3.Adapt to various complex welds, spot welding of various devices, and welds of thin plates within 1mm;

4.The imported ceramic concentrating cavity is used, which is corrosion-resistant, high-temperature resistant, and the life of the cavity is 8 to 10 years), and the life of the argon lamp is more than 8 million; special automatic tooling and fixtures can be customized to achieve mass production of products.

Applications:

It is widely used in the mass production of optical communication devices, electronic components, medical machinery, clocks, glasses, digital communication products, precision parts, hardware and other industries, as well as the repair of large mold welding, die casting and injection molding.

Post time: Jun-02-2023