Understanding what are the common technical problems in laser cutting is the first step from frustration to flawless execution. While laser cutters are marvels of precision, every operator has faced that moment of disappointment: a perfect design ruined by jagged edges, incomplete cuts, or scorch marks. It’s a common experience, but the good news is that most issues are fixable.

The key is to think like a technician and cut like a professional. Every cutting error is a symptom pointing to a root cause, whether it’s in the machine’s settings, its delicate optics, or its mechanical parts. This guide provides a systematic framework to diagnose and solve these issues fast, starting with the most frequent culprits.

First Response: Fixing Common Cut Quality Defects

Are you seeing poor results on your workpiece? If you’re asking how to improve laser cutting quality, your first stop should always be the machine’s core settings. These factors can affect the quality of a laser cut more than anything else.

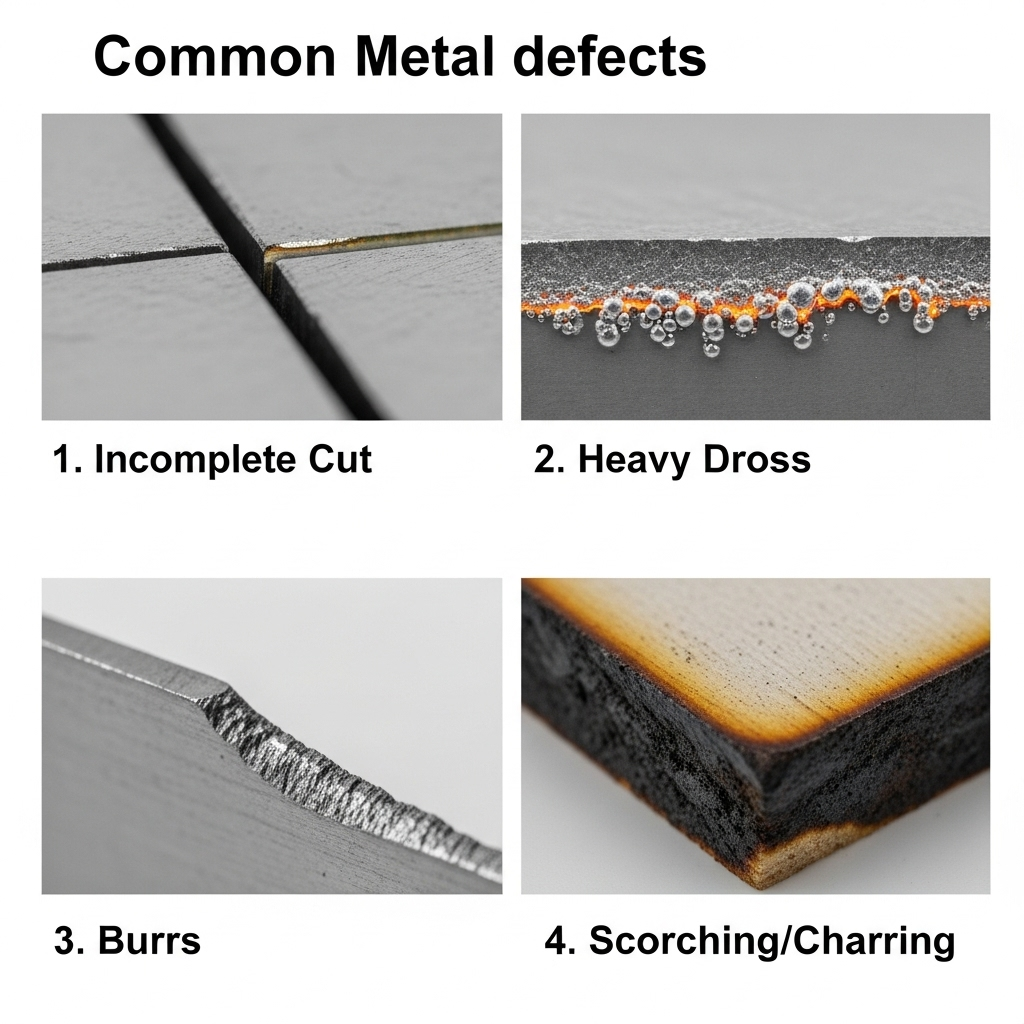

Symptom: Incomplete Cuts, Dross, Burrs, or Rough Edges

These are the most common complaints, and they almost always trace back to an imbalance in the primary process parameters. Before you tear the machine apart, check these four things:

These are the most common complaints, and they almost always trace back to an imbalance in the primary process parameters. Before you tear the machine apart, check these four things:

1.Laser Power & Cutting Speed: These two work in tandem. If your speed is too high for the power level, the laser won’t cut through. If it’s too slow, excess heat builds up, causing melting, burrs, and a rough edge. Find the “sweet spot” for your specific material and thickness.

2.Focal Position: This is critical. An unfocused beam diffuses its energy, leading to a wider, weaker cut. Ensure the beam is perfectly focused on or just slightly below the material’s surface for the cleanest result.

3.Assist Gas Pressure: The assist gas (like oxygen or nitrogen) does more than just clear molten material from the cut path. If the pressure is too low, dross will cling to the bottom edge. If it’s too high, it can cause turbulence and a rough, wavy cut.

4.Nozzle Condition & Size: The nozzle directs the assist gas into the cut. A damaged, dirty, or clogged nozzle will create a chaotic gas jet, ruining cut quality. Similarly, using a nozzle with an opening that is too large for the job can reduce pressure and cause issues. Visually inspect the nozzle daily. Ensure it’s clean, centered, and free of nicks or spatter.

If adjusting these “Big 4” doesn’t solve the issue, the problem might be mechanical, like vibrations from a worn-out belt or bearing.

The Second Troubleshooting: System-Wide Failures

Sometimes the problem isn’t the cut quality—it’s that the machine won’t work at all. Before you panic, run through this simple safety and systems checklist.

Symptom: Machine Won’t Power On or Laser Fails to Fire

In these cases, the solution is often surprisingly simple and related to the machine’s built-in safety features.

Check the Emergency Stop: Is the button pushed in? This is the most common reason for a “dead” machine.

Check Safety Interlocks: Are all access panels and the main lid completely closed? Most machines have sensors that prevent the laser from firing if any door is ajar.

Check the Cooling System: Is the water chiller on, and is water flowing? A laser tube generates immense heat and will not fire without active cooling to protect itself from damage.

Check Fuses & Breakers: Look for a tripped circuit breaker or a blown fuse in your workshop’s panel or on the machine itself.

The Deep Dive: A Root Cause Analysis Checklist

If the quick fixes don’t work, it’s time to dig deeper. A systematic check of each machine subsystem will help you pinpoint the root cause.

Is the Problem in the Optical Path?

A laser beam is only as good as the path it travels.

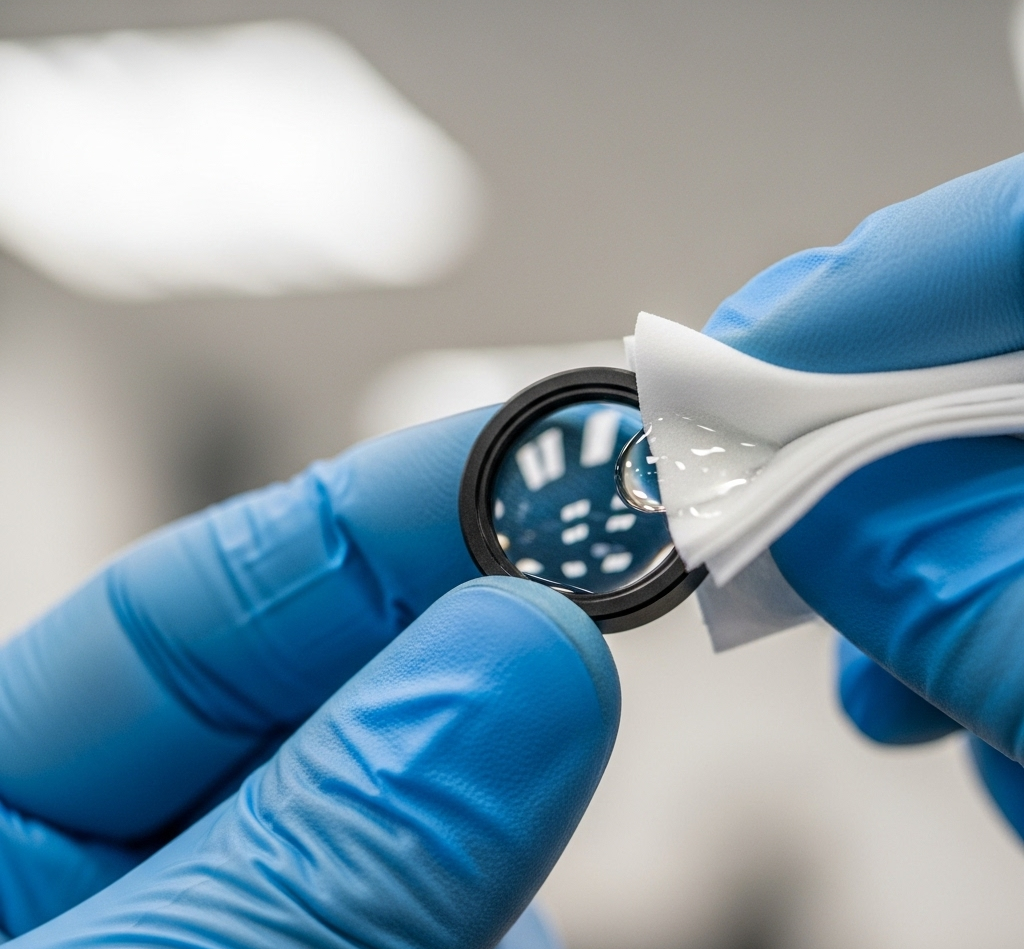

Common Optic Flaws: A dirty or scratched focus lens or mirror is a major culprit for power loss. Dust, smoke, and resin can bake onto the surface, blocking and scattering the beam. A misaligned beam won’t hit the center of the lens, resulting in a weak, angled cut.

Solution: Regularly inspect and clean all optics with proper lens wipes. Perform a beam alignment check to ensure the beam is traveling true from the tube to the material.

Is the Problem in the Mechanical System?

Your laser head moves on a precise motion system. Any slop or error here translates directly to the cut.

Common Motion Flaws: Loose belts, worn bearings, or debris on the guide rails can cause vibrations, leading to wavy lines or inaccurate dimensions.

Solution: Regularly inspect all motion components. Keep the guide rails clean and lubricated according to your manufacturer’s specifications. Check belt tension; they should be taut but not overly tight.

Is the Problem Material-Specific?

Different materials behave differently under the laser.

Challenge: Stainless Steel (Oxidation): When cutting stainless steel with oxygen, you can get a blackened, oxidized edge.

Solution: Use a high-purity nitrogen assist gas to create a clean, oxide-free edge.

Challenge: Reflective Metals (Aluminum, Copper): Shiny materials can reflect the laser beam back into the machine, potentially damaging the optics.

Solution: Use higher power and a pulsed mode to ensure the energy is absorbed. Some operators use anti-reflection coatings or surface treatments.

Beyond Repairs: When to Upgrade Your Laser Cutter

Sometimes, persistent repair costs, outdated technology, or new production demands make it clear: it’s time to stop fixing and start upgrading. If you’re looking to increase capacity, improve precision, or cut new materials, investing in a new laser cutter might be your next logical step.

Understanding Laser Cutter Machine Price

When you search for a laser cutter price, you’ll find a massive range. The final cost is determined by a few key variables that directly impact performance and capability.

|

Factor |

Price Impact |

Description |

|

Power (Watts) |

High |

A 1500W machine can handle thin-to-medium gauge steel, while a 4000W, 6000W is required for production cutting of thick plate steel at high speeds. The price scales dramatically with power. |

|

Type & Size |

High |

The primary distinction is between CO₂ lasers (great for non-metals like acrylic and wood) and Fiber lasers (dominant for metal cutting). Additionally, the size of the cutting bed is a major price driver. |

|

Laser Source |

Medium |

The brand of the laser resonator (the part that creates the laser beam) is crucial. Premium brands like IPG, Raycus offer higher efficiency, better beam quality, and longer lifespans, but come at a higher initial cost. |

The Best Solution: A Proactive Preventative Maintenance Schedule

The best way to solve problems is to prevent them from ever happening. A simple maintenance routine is the most effective way to ensure machine reliability and high-quality results.

Daily Maintenance (Under 5 Minutes)

Check and clean the nozzle tip.

Visually inspect and clean the focus lens.

Weekly Maintenance

Clean all mirrors in the optical path.

Check the water chiller’s level and look for any contamination.

Wipe down the cutting bed slats to remove residue.

Monthly Maintenance

Lubricate all guide rails and mechanical bearings per the manual.

Inspect all belts for proper tension and signs of wear.

Clean out the machine’s internal exhaust fan and ducting.

Conclusion: Reliability Through Systematic Care

Most laser cutting problems are not mysteries. They are solvable issues that can be traced back to a specific cause. By adopting a systematic troubleshooting approach—checking settings, then optics, then mechanics—you can solve the vast majority of your day-to-day cutting headaches.

Ultimately, proactive prevention is always better and cheaper than reactive repair. A consistent preventative maintenance schedule is the true secret to machine reliability and perfect cuts, every time.

For complex repairs, persistent issues, or guidance on investing in new equipment, don’t hesitate to contact a trusted service provider for professional support.

Frequently Asked Questions (FAQ)

Q:What causes inconsistent laser power output?

A:Inconsistent power often points to a failing laser tube, a dirty or damaged focus lens, or a problem with the high-voltage power supply. Also, check that your water chiller is maintaining a stable temperature.

Q:How often should I clean my laser’s lens and mirrors?

A:For heavy use, a quick daily check and cleaning of the focus lens is recommended. A full cleaning of all mirrors should be done weekly. If you’re cutting materials that produce a lot of smoke or residue, like wood or acrylic, you may need to clean them more frequently.

Q:What materials should I never cut with a laser?

A:Never cut materials containing chlorine, like PVC or vinyl. When heated, they release toxic chlorine gas that is extremely corrosive and can permanently damage your machine’s optics and mechanics, not to mention being hazardous to your health. Avoid materials with unknown compositions.

Post time: Aug-04-2025