This handheld laser welding safety precautions guide is your first step toward mastering this technology without risking your well-being. Handheld laser welders are transforming workshops with incredible speed and precision, but this power comes with serious, often invisible, risks.

This guide provides essential safety precautions for handheld laser welding and is intended to supplement, not replace, the specific safety manual provided by your equipment manufacturer. Always refer to your manufacturer’s manual for detailed operational and safety instructions.

Your First Line of Defense: Mandatory Personal Protective Equipment

Are handheld laser welders safe? Yes, but only if you use the right gear. Your standard arc welding equipment is dangerously inadequate for laser work. Everyone in or near the welding area must be properly equipped.

Laser Safety Glasses: This is the most critical piece of PPE. They must be rated with an Optical Density (OD) of OD≥7+ specifically for the wavelength of your laser (typically around 1070 nm). Before every use, you must physically inspect the eyewear to confirm these ratings are printed correctly on the lens or frame. Never use unmarked or damaged glasses. Everyone with a potential line of sight to the laser needs them.

Flame-Retardant Clothing: Full skin coverage is essential. Wear FR-rated garments to protect against the laser beam, sparks, and heat.

Heat-Resistant Gloves: Protect your hands from thermal energy and accidental beam reflections.

Respirator: Laser welding fumes contain microscopic particles that can be harmful. Use a fume extraction system and, if needed, wear a respirator (N95 or higher) to protect your lungs.

Safety Shoes: Standard industrial-grade footwear is required to protect against dropped parts and other shop hazards.

Creating a Fortress: How to Set Up a Safe Laser Zone

Properly setting up the work environment is just as important as wearing personal protective equipment. You must create a formal Laser Controlled Area (LCA) to contain the beam.

Understanding Class 4 Lasers

Handheld laser welders typically fall into Class 4 of the ANSI Z136.1 laser classification system. This classification denotes the most hazardous laser systems. Class 4 lasers are capable of causing permanent eye damage from direct, reflected, or even diffusely scattered beams, and can cause skin burns and ignite fires. This high power underscores the absolute necessity of strict safety protocols.

Establish a Physical Barrier

You must enclose the welding operation to protect others. This can be done using:

1.Certified laser safety curtains or screens.

2.Permanent structural walls.

3.Anodized aluminum panels rated for Class 4 lasers.

Control Access

Only authorized, trained, and fully equipped personnel should ever enter the LCA.

Warning Signs

Post clear “DANGER” signs at every entrance, as required by the ANSI Z136.1 standard. The sign must include the laser symbol and state “Class 4 Laser – Avoid eye or skin exposure to direct or scattered radiation.”

Mitigate Fire and Fume Risks

Fire Prevention: Remove all flammable and combustible materials from within at least a 10-meter radius of the LCA. Keep a suitable, maintained fire extinguisher (e.g., ABC type, or Class D for combustible metals) easily accessible.

Fume Extraction: What is the greatest hazard while laser welding? While eye damage is number one, fumes are a serious concern. Use a local fume extractor with the intake positioned as close to the weld as possible to capture harmful particles at the source.

The Principle of Handheld Laser Welding

Think of a handheld laser welder like an incredibly powerful and precise magnifying glass. Instead of focusing sunlight, it generates and focuses a beam of light with immense energy onto a tiny spot.

The process starts at the laser source, typically a fiber laser generator. This unit creates a highly concentrated beam of infrared light. This light travels through a flexible fiber optic cable to the handheld welding torch.

Inside the torch, a series of optics focuses this powerful beam down to a pinpoint. When the operator pulls the trigger, this focused energy hits the metal, causing it to melt almost instantly and form a weld pool. As the operator moves the torch along the joint, the molten metal flows together and solidifies, creating a strong, clean seam.

This principle is what gives laser welding its key advantages.

Low Heat Input & Reduced Distortion

The extremely high power density deposits energy into the material almost instantaneously. This rapid heating causes the metal at the focal point to melt and even vaporize before significant heat can conduct into the surrounding material.

Small Heat-Affected Zone (HAZ): Because there’s little time for thermal diffusion, the zone of material that is structurally altered by the heat but not melted—the HAZ—is very narrow.

Minimized Warping: Thermal distortion is caused by the expansion and contraction of heated material. With a much smaller volume of metal being heated, the overall thermal stresses are significantly lower, resulting in minimal warping and a more dimensionally stable final product.

High Precision & Control

The precision of laser welding is a direct result of the small, controllable size of the laser beam.

Small Spot Size: The laser can be focused down to a spot size of just a few tenths of a millimeter. This allows for the creation of very narrow, fine welds that are impossible with conventional methods like MIG or TIG welding.

Targeted Energy: This precision makes it ideal for welding thin materials, intricate components, or working close to heat-sensitive electronics without causing damage.

Incredible Speed & Deep Penetration

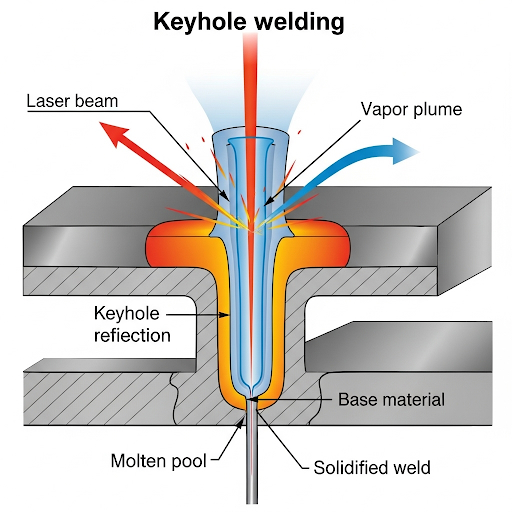

The intense energy density leads to a highly efficient welding mechanism known as keyhole welding.

Keyhole Formation: The power density is so high that it doesn’t just melt the metal; it vaporizes it, creating a deep, narrow cavity of metal vapor called a “keyhole.”

Efficient Energy Transfer: This keyhole acts like a channel, allowing the laser beam to penetrate deep into the material. The laser energy is absorbed efficiently throughout the depth of the keyhole, not just on the surface.

Rapid Welding: As the laser moves along the joint, the molten metal flows around the keyhole and solidifies behind it, creating a deep, narrow weld. This process is significantly faster than traditional methods that rely on slower heat conduction to melt the material. This results in deep penetration welds at high travel speeds, boosting productivity.

The Operator’s Checklist: Critical In-Use Safety Precautions

Once the gear is on and the zone is secure, safe operation is key.

Perform a Pre-Use Inspection: Before every use, visually inspect the equipment. Check the fiber optic cable for kinks or damage, ensure the welding nozzle is clean and secure, and verify that all safety features are functioning correctly.

Regular Maintenance: Beyond daily inspections, establish and adhere to a schedule for routine maintenance of the laser system. This includes checking cooling systems and optic cleanliness. Ensure fume extraction systems are regularly cleaned and filters replaced to maintain efficiency. Proper maintenance prevents equipment malfunctions that could lead to hazardous situations.

Respect Reflection Hazards: Specular (mirror-like) reflections from shiny surfaces like aluminum or stainless steel are the most dangerous hazard after the direct beam.

Master Your Posture and Angle: Always keep your body out of the direct and potential reflection paths. Maintain a welding angle between 30 and 70 degrees to minimize dangerous reflections back toward you.

Use the Built-in Safety Features: Never bypass safety mechanisms.

Key Switch: Prevents unauthorized use.

Two-Stage Trigger: Prevents accidental firing.

Workpiece Contact Circuit: Ensures the laser can only fire when the nozzle is touching the workpiece.

Ensure Proper Grounding: Always attach the earth clamp securely to the workpiece before starting. This prevents the machine’s casing from becoming dangerously energized.

Emergency Response: What to Do in an Incident

Even with every precaution, you must be prepared to act swiftly. Every person working in or near the LCA must know these steps.

Suspected Eye Exposure

Any suspected eye exposure to a direct or reflected beam is a medical emergency.

1.Stop work immediately and shut down the laser system.

2.Inform your Laser Safety Officer (LSO) or supervisor at once.

3.Seek immediate medical evaluation from an ophthalmologist. Have the laser’s specifications (Class, wavelength, power) ready for the medical staff.

4.Do not rub the eye.

Skin Burns or Fire

For a Skin Burn: Treat it as a thermal burn. Immediately cool the area with water and seek first aid. Report the incident to your LSO.

For a Fire: If a small fire starts, use the appropriate fire extinguisher. If the fire is not immediately controllable, activate the nearest fire alarm and evacuate the area.

Knowledge is Power: The Laser Safety Officer (LSO)

According to the ANSI Z136.1 standard, any facility using a Class 4 laser must designate a Laser Safety Officer (LSO).

The LSO is the person responsible for the entire laser safety program. They don’t need a special external certification, but they must have sufficient training to understand the risks, implement control measures, approve procedures, and ensure all personnel are properly trained. This role is the cornerstone of your safety culture.

Frequently Asked Questions (FAQs)

Q: Are handheld laser welders safe for a small workshop?

A: Yes, if you follow every protocol. The safety standards, including appointing an LSO and creating an LCA, apply to every organization using a Class 4 laser, regardless of its size.

Q: What protection do you need for laser welding?

A: You need wavelength-specific laser safety glasses, FR clothing, gloves, and respiratory protection in a properly designed Laser Controlled Area (LCA).

Q: What kind of training does a Laser Safety Officer need?

A: The ANSI Z136.1 standard requires the LSO to be knowledgeable and competent, but does not mandate a specific external certification. Their training should be sufficient to understand laser physics and hazards, evaluate risks, determine appropriate control measures, and manage the overall safety program, including training records and audits.

Post time: Aug-01-2025