Proactive, routine laser cutter maintenance is the single most important factor in your machine’s performance, reliability, and operational lifespan. Viewing maintenance not as a chore, but as a strategic investment, allows you to prevent costly, unplanned downtime and ensure consistent, high-quality output. A well-maintained machine extends the life of expensive components like the laser tube and optics, significantly reduces fire risk, and protects your investment.

Your Quick-Start Maintenance Checklist

This scannable checklist covers the most critical tasks. For a deeper understanding of each step, refer to the detailed sections below.

Daily Tasks (Before Each Shift)

-

Inspect and clean the focus lens and nozzle.

-

Check the chiller water level and temperature.

-

Empty the crumb/slag tray to prevent fire hazards.

-

Wipe down the workbed and interior to remove debris.

Weekly Tasks (Every 40-50 Hours of Use)

-

Deep clean all mirrors and the focus lens.

-

Clean the chiller’s air filters and the machine’s air intake filters.

-

Wipe down and lubricate the guide rails.

-

Inspect and clean the fume extraction fan and ducting.

Monthly & Semi-Annual Tasks

-

Inspect drive belts for proper tension and wear.

-

Deep clean the workbed (honeycomb or slat).

-

Check electrical connections in the control cabinet.

-

Flush and replace chiller water every 3-6 months.

Essential Safety Protocols for All Maintenance

Safety is non-negotiable. While a laser cutter is a Class 1 laser product during normal operation, its internal components are often Class 3B or 4, capable of causing severe eye and skin injury.

-

Always Power Down: Before any physical maintenance, completely power down and unplug the machine from its electrical supply. This is a critical lockout/tagout (LOTO) step.

-

Wear Proper PPE: Use safety glasses to protect from debris and clean, powder-free gloves when handling optics to prevent contamination from skin oils.

-

Fire Prevention is Key: The laser process inherently creates a fire risk. Keep the machine and surrounding area free of clutter and flammable debris. A suitable, regularly inspected CO2 fire extinguisher must be easily accessible near the machine.

-

Maintain a Maintenance Log: A logbook is your most critical tool for tracking tasks, identifying performance trends, and ensuring accountability.

The Optical Pathway: How to Keep Your Laser Beam Powerful and Precise

Dirty optics are the most common cause of poor cutting performance. A contaminant on a lens or mirror doesn’t just block the beam—it absorbs energy, creating intense heat that can permanently damage the delicate coatings and even crack the optic.

Why Dirty Optics Kill Laser Power

Any residue, from a fingerprint to a speck of dust, absorbs laser energy. This localized heat can cause microscopic fractures in the anti-reflective coatings, leading to pitting and catastrophic failure. Cleaning the optical pathway is essential to prevent this damage.

Step-by-Step Guide: Cleaning Lenses and Mirrors

Materials Needed:

-

High-purity (90% or higher) isopropyl alcohol (IPA) or denatured alcohol.

-

Optical-grade, lint-free lens tissues or new, clean cotton swabs.

-

An air blower to remove loose dust first.

What to Avoid:

-

Never use ammonia-based cleaners like Windex, as they will permanently damage the coatings.

-

Avoid standard paper towels or shop rags, which are abrasive and leave behind lint.

The Cleaning Process:

-

Safety First: Power off the machine and allow optics to cool. Wear clean gloves.

-

Dust Removal: Use an air blower to gently blow loose particles off the surface.

-

Apply Solvent: Moisten your applicator (lens tissue or swab) with IPA. Never apply solvent directly onto the optic, as it can seep into the mount.

-

Wipe Gently: Use a single, gentle drag motion across the surface, then discard the tissue. For circular optics, a spiral pattern from the center outwards is effective. The goal is to lift contaminants, not scrub them.

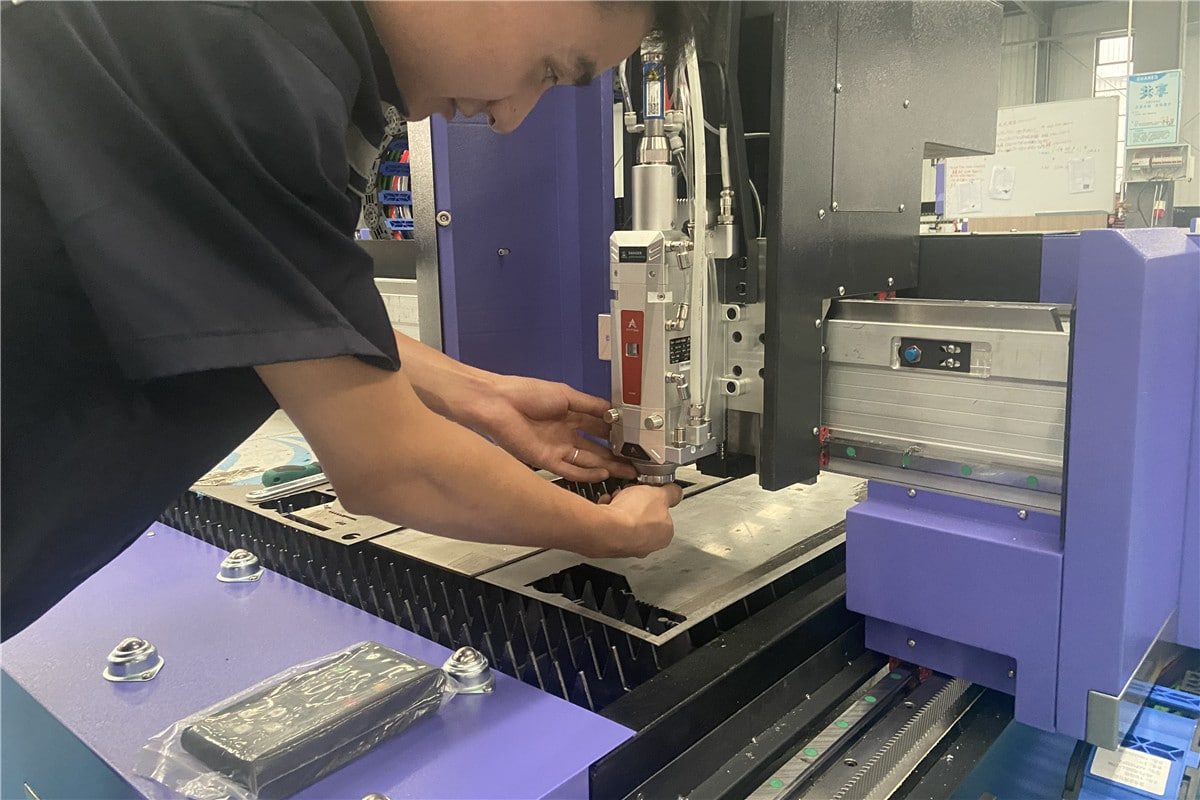

The Motion System: Ensuring Smooth and Accurate Movement

The accuracy of your cuts depends entirely on the mechanical integrity of the motion system. Proper maintenance eliminates issues like dimensional inaccuracies and banding.

Lubrication 101: Clean Before You Lube

This is the golden rule of lubrication. Never apply fresh lubricant over old, contaminated grease. The mix of new lubricant and old grime creates an abrasive paste that rapidly accelerates wear on bearings and rails. Always wipe rails clean with a lint-free cloth before applying a thin, even layer of lubricant.

-

Recommended Lubricants: Use manufacturer-specified lubricants like white lithium grease or a PTFE-based dry lubricant, especially in dusty environments.

-

Avoid: Do not use general-purpose oils like WD-40. They are too thin for lasting lubrication and attract dust, causing more harm than good.

How to Check and Adjust Belt Tension

Proper belt tension is a balance. A loose belt causes backlash, resulting in “ghosting” in engravings or circles being cut as ovals. An overly tight belt strains motor bearings and can permanently stretch the belt.

-

Check for Tension: Belts should be taut with a slight amount of give when pressed firmly, but with no visible sag. When you move the gantry by hand, there should be no delay or “slop.”

The Cooling System: Your Laser Tube’s Life Support

The water chiller is the life-support system for your laser tube. Failure to properly cool the tube will lead to its rapid and irreversible destruction.

The Golden Rule: Distilled Water Only

This is a non-negotiable requirement. Tap water contains minerals that will precipitate and form an insulating layer of scale inside the laser tube, causing it to overheat. Furthermore, these minerals make tap water electrically conductive, creating a risk of high-voltage arcing that can destroy the power supply.

Chiller Maintenance Checklist

-

Clean Filters: Weekly, clean the mesh dust filters on the chiller’s air intakes to ensure proper airflow.

-

Clean Condenser: Monthly, power off the unit and use a soft brush or compressed air to clean dust from the radiator-like condenser fins.

-

Replace Water: Drain and replace the distilled water every 3-6 months to prevent contamination and algae growth.

Airflow & Extraction: Protecting Your Lungs and Your Lens

The fume extraction and air-assist systems are critical for operator safety and machine health. They remove hazardous fumes and prevent residue from contaminating your optics and mechanical parts.

Fume Extraction Maintenance

Residue can build up on the blades of the main exhaust fan, restricting airflow and unbalancing the fan. On a weekly or monthly basis, disconnect the fan from power and thoroughly clean the impeller blades. Inspect all ducting for blockages or leaks and seal any damage immediately.

Air-Assist: The Unsung Hero

The air-assist system does three critical jobs: it blows molten material out of the cut, suppresses flames, and creates a high-pressure curtain of air that actively protects the focus lens from smoke and debris. A clogged nozzle or failing air compressor is a direct threat to your expensive focus lens and should be addressed immediately.

Troubleshooting Common Problems: A Maintenance-First Approach

| Problem | Probable Maintenance Cause | Solution |

| Weak or Inconsistent Cutting | 1. Dirty lens/mirrors. 2. Beam misalignment. | 1. Clean all optics per the guide above. 2. Perform a beam alignment check.

|

| Wavy Lines or Skewed Shapes | 1. Loose drive belts. 2. Debris on guide rails. | 1. Check and adjust belt tension. 2. Clean and lubricate rails.

|

| Excessive Flames or Charring | 1. Clogged air-assist nozzle. 2. Weak fume extraction. | 1. Clean or replace the nozzle. 2. Clean the exhaust fan and ducting.

|

| “Water Fault” Alarm | 1. Low water in chiller. 2. Clogged chiller filter. | 1. Top up with distilled water. 2. Clean the chiller’s air filter.

|

FAQ About Laser Cutter Maintenance

How often should I really clean my laser lens?

It depends on the material. For smoky materials like wood, inspect it daily. For cleaner materials like acrylic, a weekly check may be sufficient. A good rule of thumb is to inspect the lens and mirrors daily.

What’s the biggest fire risk I should watch out for?

An accumulation of small, flammable off-cuts and residue in the crumb tray or on the workbed is the most common fuel for a machine fire. Empty the crumb tray daily to minimize this risk.

Can I use tap water in my chiller just once?

No. Using tap water, even once, introduces minerals that can immediately begin to cause scale buildup and conductivity issues. Stick to distilled water only to protect your laser tube and power supply.

Conclusion

Consistent CO2 laser maintenance is the key to unlocking your machine’s full potential and protecting your investment. By following a regular schedule, you transform maintenance from a reactive chore into a proactive strategy that ensures quality, safety, and profitability. A few minutes of prevention is worth hours of troubleshooting and repair.

Need expert help? Schedule a professional service audit with our technicians to ensure your machine is calibrated for peak performance.

Post time: Oct-08-2025