The versatility of laser cutter presents vast creative and industrial opportunities. However, achieving optimal results while ensuring operational safety is entirely dependent on material compatibility. The critical distinction between a clean, precise cut and a hazardous failure lies in knowing which materials are suitable for the process and which pose a significant risk to the operator and the equipment.

This guide is your definitive map. We’ll get straight to the point, showing you what you can cut, and more importantly, what you should never put inside your machine.

The Quick Answer: A Cheat Sheet for Laser Safe Materials

Let’s cut to the chase. You need answers now, so here’s a quick-reference chart for what you can and can’t use.

|

Material |

Status |

Hazard / Key Consideration |

|

Safe Materials |

||

|

Wood (Natural, Solid) |

√ |

Flammable. Hardwoods require more power. |

|

Acrylic (PMMA, Plexiglass) |

√ |

Excellent results, creates a flame-polished edge. |

|

Paper & Cardboard |

√ |

High fire risk. Never leave unattended. |

|

Fabrics (Cotton, Felt, Denim) |

√ |

Natural fibers cut cleanly. |

|

Polyester / Fleece / Mylar |

√ |

Creates a sealed, fray-free edge. |

|

Natural Cork |

√ |

Cuts well, but is flammable. |

|

POM (Acetal / Delrin®) |

√ |

Great for engineering parts like gears. |

|

Caution Materials |

||

|

Plywood / MDF |

! |

Caution: Glues and binders can release toxic fumes (e.g., formaldehyde). |

|

Leather (Vegetable-Tanned Only) |

! |

Caution: Chrome-tanned and other types can release toxic heavy metals like Chromium-6. |

|

Hazardous Materials |

||

|

Polyvinyl Chloride (PVC, Vinyl) |

× |

Releases chlorine gas. Creates hydrochloric acid, which destroys your machine and is toxic to inhale. |

|

ABS Plastic |

× |

Releases cyanide gas. Melts into a gooey mess and is highly toxic. |

|

Thick Polycarbonate (Lexan) |

× |

Catches fire, discolors, and cuts very poorly. |

|

HDPE (Milk Jug Plastic) |

× |

Catches fire and melts into a sticky mess. |

|

Coated Carbon Fiber / Fiberglass |

× |

The binding resins release highly toxic fumes when burned. |

|

Polystyrene / Polypropylene Foam |

× |

extreme fire hazard. Catches fire instantly and produces flaming drips. |

|

Any material containing halogens |

× |

Releases corrosive acid gases (e.g., Fluorine, Chlorine). |

The “Yes” List: A Deep Dive into Laser-Cuttable Materials

Now that you have the essentials, let’s explore the best laser cutting materials in more detail. Success isn’t just about the material itself, but also understanding how your laser interacts with it.

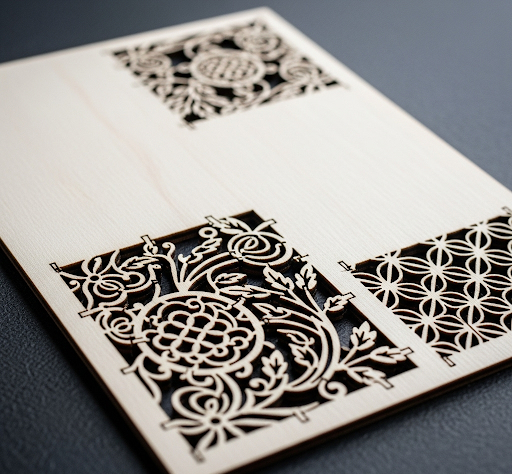

Woods and Wood Composites

Wood is a favorite for its warmth and versatility. However, not all woods behave the same way.

Natural Woods: Softwoods like Balsa and Pine cut like butter on low power. Hardwoods like Walnut and Maple are gorgeous but require more laser power and slower speeds due to their density.

Engineered Woods: Plywood and MDF are cost-effective workhorses. Be aware that the glues in plywood can cause inconsistent cuts. MDF cuts smoothly but produces a lot of fine dust, so good ventilation is a must.

Pro-Tip: To prevent smoke stains and charring on the surface of the wood, apply a layer of masking tape over the cut line before you start. You can peel it off afterward for a perfectly clean finish!

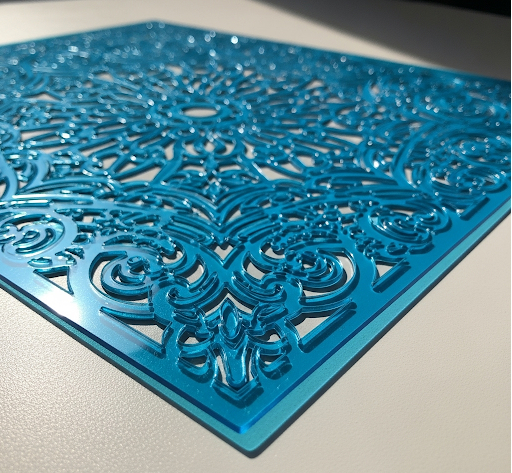

Plastics and Pol

Plastics offer a modern, clean look, but choosing the right one is critical.

Acrylic (PMMA): This is the star of laser-cuttable plastics. Why? It vaporizes cleanly and leaves a beautiful, flame-polished edge. It’s perfect for signs, jewelry, and displays.

POM(Acetal / Delrin®): An engineering plastic known for its high strength and low friction. If you’re making functional parts like gears or machine components, POM is an excellent choice.

Polyester (Mylar): Often found in thin sheets, Mylar is great for making flexible stencils or thin films.

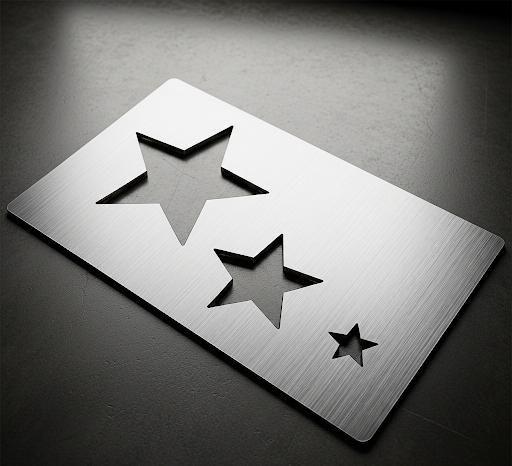

Metals (The Fiber Laser Domain)

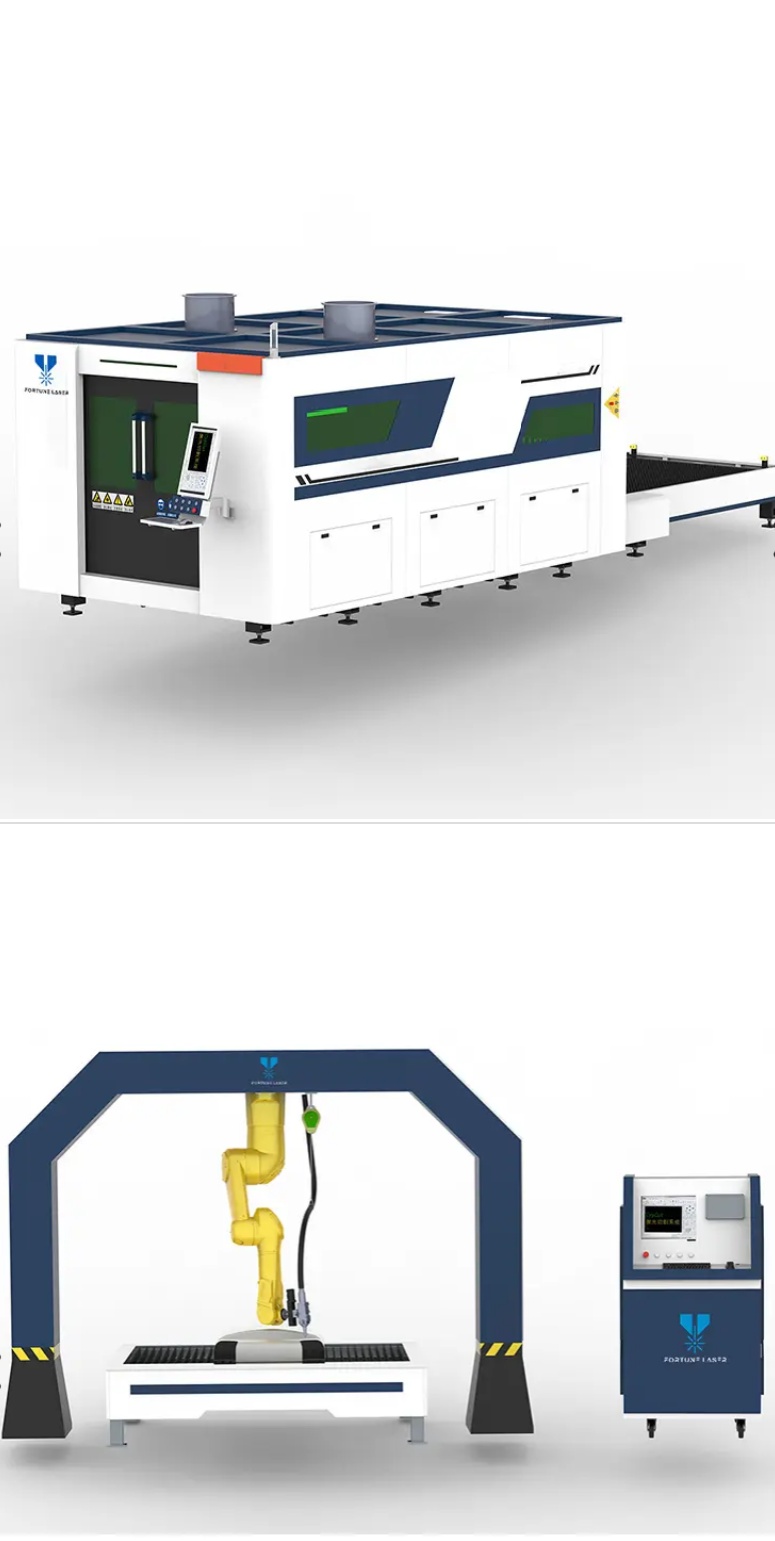

Can you cut metal with a laser? Absolutely! But here’s the catch: you need the right kind of laser.

The key difference is the laser’s wavelength. While a CO₂ laser is great for organic materials, you need a Fiber Laser for metals. Its shorter wavelength ( 1μm) is absorbed much more efficiently by metallic surfaces.

Steel and Stainless Steel: These are commonly cut with fiber lasers. For a clean, non-oxidized edge on stainless steel, nitrogen is used as an assist gas.

Aluminum: Tricky due to its high reflectivity and thermal conductivity, but easily handled by modern high-power fiber lasers.

Copper and Brass: These are extremely reflective and can potentially damage a laser if not handled correctly. They require specialized, high-power fiber laser systems.

Organics and Textiles

From paper prototypes to custom fashion, lasers handle organic materials with ease.

Paper & Cardboard: These are incredibly easy to cut with very low power. The biggest concern here is the risk of fire. Always use good air assist to blow out flames and never leave the machine unattended.

Leather: You must use vegetable-tanned leather. Chrome-tanned and artificial leathers often contain chemicals (like chromium and chlorine) that release toxic and corrosive fumes.

Fabrics: Natural fibers like cotton, denim, and felt cut cleanly. The real magic happens with synthetic fabrics like polyester and fleece. The laser melts and seals the edge as it cuts, resulting in a perfect, fray-free finish.

The “DO NOT CUT” List: Hazardous Materials to Avoid

This is the most important section of this guide. Your safety, and the health of your machine, is the number one priority. Cutting the wrong material can release toxic gases, start fires, and permanently corrode your laser cutter’s components.

When in doubt, don’t cut it. Here are the materials you should never put in your laser cutter:

Polyvinyl Chloride (PVC, Vinyl, Pleather): This is the worst offender. When heated, it releases chlorine gas. When mixed with moisture in the air, it creates hydrochloric acid, which will destroy your machine’s optics, corrode its metal components, and is incredibly dangerous to your respiratory system.

ABS: This plastic tends to melt into a gooey mess rather than vaporizing cleanly. More importantly, it releases hydrogen cyanide gas, which is a highly toxic poison.

Thick Polycarbonate (Lexan): While very thin polycarbonate can be cut, thicker sheets absorb the laser’s infrared energy poorly, leading to severe discoloration, melting, and a major fire risk.

HDPE (High-Density Polyethylene): You know those plastic milk jugs? That’s HDPE. It catches fire very easily and melts into a sticky, burning mess that is impossible to cut cleanly.

Fiberglass & Coated Carbon Fiber: The danger isn’t the glass or carbon itself, but the epoxy resins that bind them. These resins release highly toxic fumes when burned.

Polystyrene and Polypropylene Foams: These materials catch fire almost instantly and produce dangerous, flaming drips. Avoid them at all costs.

Your Laser Journey Starts with Safety

Understanding laser cutting materials is the foundation of every great project. By choosing the right material for your laser type and, most importantly, avoiding the hazardous ones, you’re setting yourself up for success.

Always remember the three golden rules:

1.Know Your Material: Identify it before you even think about cutting.

2.Match the Laser: Use CO₂ for organics and Fiber for metals.

3.Prioritize Safety: Proper ventilation and avoiding forbidden materials are non-negotiable.

Frequently Asked Questions (FAQ)

Q1: Which material can be cut by laser?

A: A huge variety! The most common are wood, acrylic, paper, vegetable-tanned leather, and natural fabrics for CO₂ lasers. For metals like steel and aluminum, you need a Fiber laser.

Q2: Is laser cutting wood a fire hazard?

A: Yes, it can be. Wood and paper are flammable. To stay safe, always use proper air assist, keep your machine’s crumb tray clean, and never leave a laser cutter running unattended. It’s wise to keep a small fire extinguisher nearby.

Q3: What is the most dangerous material to laser cut?

A: Polyvinyl Chloride (PVC) is by far the most dangerous. It releases chlorine gas, which creates hydrochloric acid and can cause irreparable damage to both the machine and the operator’s health.

Q4: What are the best practices for material verification to avoid damaging my laser with unknown plastics?

A: Always prioritize safety: if a plastic isn’t positively identified, consider it unsafe. The definitive proof of safety is the material’s Safety Data Sheet (SDS) or a label from a trusted laser-material supplier.

Post time: Aug-11-2025