The safety and efficiency of modern railway systems depend on manufacturing components to incredibly high standards of precision. At the heart of this industrial process is laser cutting, a technology that utilizes a focused beam of light to fabricate metal parts with unparalleled accuracy.

This guide provides a detailed look at the engineering principles that govern laser cutter, explores its diverse applications from train bodies to trackside equipment, and explains why it has become a foundational tool for the railway industry.

The Technology: How a Laser Actually Cuts Steel

It’s not just a generic “beam of light”. The process is a highly controlled interaction between light, gas, and metal.

Here’s the step-by-step process:

1.Generation: Inside a power source, a series of diodes “pump” energy into fiber optic cables that have been doped with rare-earth elements. This excites the atoms and generates an intense, high-energy beam of light.

2.Focusing: This beam, often rated between 6 and 20 kilowatts (kW) for heavy industrial use, is channeled through a fiber optic cable to the cutting head. There, a series of lenses focuses it down to a tiny, incredibly powerful spot, sometimes smaller than 0.1 mm.

3.Cutting & Gas Assist: The focused beam melts and vaporizes the metal. At the same time, a high-pressure assist gas is fired through the same nozzle as the laser beam. This gas is critical and serves two purposes: it blows the molten metal cleanly out of the cut (known as the “kerf”) and it influences the cut’s quality.

Nitrogen (N2) is an inert gas used for cutting stainless steel and aluminum. It produces a perfectly clean, silver, oxide-free edge that is immediately ready for welding. This is called a “high-pressure clean cut”.

Oxygen (O2) is used for cutting carbon steel. Oxygen creates an exothermic reaction (it actively burns with the steel), which allows for much faster cutting speeds. The resulting edge has a thin layer of oxide that is acceptable for many applications.

The Application: From Main Frames to Micro-Components

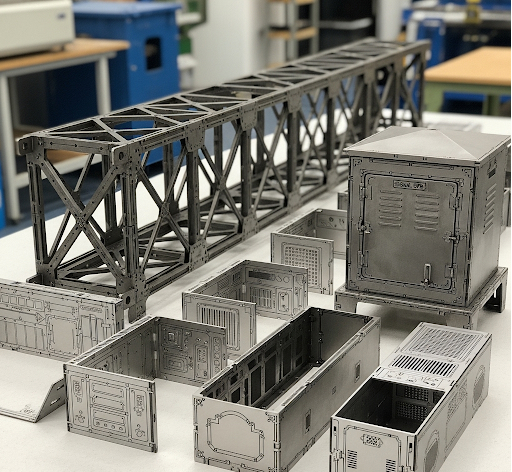

Laser cutting technology is applied throughout the entire railway manufacturing process, from the massive structural frames that ensure passenger safety to the smallest, most intricate interior components. The technology’s versatility allows it to be used for a vast array of parts, showcasing its critical role in building modern trains and the infrastructure that supports them.

Structural Components: This is the most critical area. Lasers are used to cut the main building blocks of a train, including the car body shells, the heavy-duty underframes that support the floor, and safety-critical bogie components like side frames, cross beams, and bolsters. These are often made from specialized materials like high-strength low-alloy steel, corten steel for corrosion resistance, or 5000 and 6000 series aluminum alloys for lightweight high-speed trains.

Interior and Sub-Systems: Precision is vital here, too. This includes stainless steel HVAC ducting that must fit in tight spaces, aluminum ceiling and wall panels with precise cutouts for lights and speakers, seating frames, and galvanized steel enclosures for sensitive electronics.

Infrastructure and Stations: The application extends beyond the trains themselves. Lasers cut the heavy steel plates for catenary masts, the housings for trackside signaling equipment, and complex architectural panels used to modernize station facades.

The Precision Advantage: A Deeper Dive

The term “precision” has tangible engineering benefits that go beyond just a “good fit”.

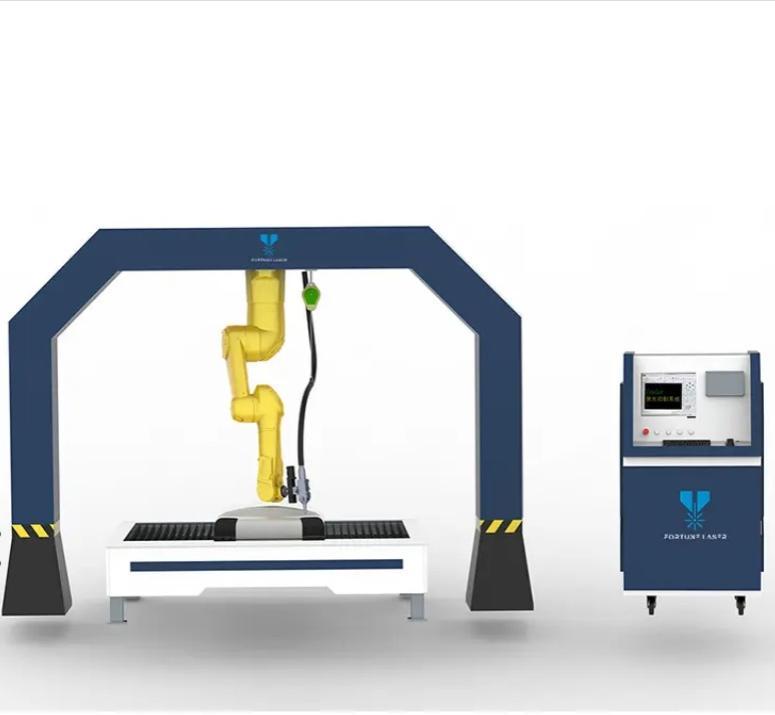

Enabling Robotic Automation: The exceptional consistency of laser-cut parts is what makes high-speed robotic welding a reality. A welding robot follows a precise, pre-programmed path and cannot adapt to variations between components. If a part is even a millimeter out of place, the entire weld can fail. Because laser cutting produces dimensionally identical components every single time, it provides the unwavering reliability that automated systems require to operate seamlessly and efficiently.

Minimizing the Heat-Affected Zone (HAZ): When you cut metal with heat, the area around the cut also gets hot, which can change its properties (like making it more brittle). This is the Heat-Affected Zone (HAZ). Because a laser is so focused, it introduces very little heat into the part, creating a tiny HAZ. This is crucial because it means the structural integrity of the metal right next to the cut remains unchanged, ensuring the material performs exactly as the engineers designed it to.

The Business Case: Quantifying the Benefits

Companies don’t invest millions in this technology just because it’s precise. The financial and logistical returns are significant.

Advanced Material Utilization: Smart “nesting” software is key. It not only fits parts together like a puzzle but also uses advanced techniques like common-line cutting, where two adjacent parts are cut with a single line, completely eliminating the scrap between them. This can push material utilization from a typical 75% to over 90%, saving immense amounts on raw material costs.

“Lights-Out” Manufacturing: Modern laser cutters are often integrated with automated loading/unloading towers. These systems can hold dozens of sheets of raw material and store finished parts. This allows the machine to run continuously through nights and weekends with minimal human supervision—a concept known as “lights-out” manufacturing—dramatically increasing productivity.

Streamlining the Entire Workflow: The benefits multiply downstream.

1. No Deburring: A clean initial cut eliminates the need for a secondary grinding station to remove sharp edges. This directly saves labor costs, improves worker safety by removing grinding hazards, and accelerates the overall production workflow.

2. No Rework: Precisely cut parts ensure a perfect fit, eliminating time-wasting manual adjustments during assembly. This directly accelerates production speed, increases throughput, and results in a higher-quality final product.

3. Simplified Supply Chain: Cutting parts on-demand from digital files reduces the need to stock large inventories, lowering storage costs, minimizing waste, and increasing operational agility.

The Right Tool for the Job: An Expanded Comparison

Optimal tool selection in a professional fabrication environment is determined by a multi-variable analysis of production speed, precision tolerance, operational cost, and material properties. Consequently, a laser is not a universally applicable solution.

|

Method |

Best For |

Key Advantage |

Key Disadvantage |

|

Fiber Laser Cutting |

High-precision cutting on sheets up to ~25mm (1 inch) thick. Ideal for stainless steel and aluminum. |

Unmatched precision, clean edges, very small HAZ, and high speed on thin materials. |

High initial capital cost. Not as effective on extremely thick plates. |

|

Plasma |

Cutting thick steel plates (>25mm) quickly where perfect edge quality is not the top priority. |

Very high cutting speed on thick materials and lower initial cost than a high-power laser. |

Larger HAZ, less precise, and produces a beveled edge that often requires grinding. |

|

Waterjet |

Cutting any material (metal, stone, glass, composites) without heat, especially heat-sensitive alloys or very thick metal. |

No HAZ at all, extremely smooth edge finish, and incredible material versatility. |

Much slower than laser or plasma, and has a higher operating cost due to abrasives and pump maintenance. |

In conclusion, fiber laser cutting is far more than just a method for shaping metal; it’s a foundational technology in the digital manufacturing ecosystem of the modern railway industry. Its value lies in the powerful combination of extreme precision, high-speed production, and deep integration with factory-wide systems.

By enabling advanced automation like robotic welding, minimizing the Heat-Affected Zone to preserve material strength, and providing the flawless edge quality required to meet stringent safety standards like EN 15085, it has become a non-negotiable tool.

Ultimately, laser cutting provides the engineering certainty and quality assurance necessary to build the safe, reliable, and technologically advanced railway systems of today.

Post time: Aug-22-2025