Choosing the appropriate industrial cleaning technology is a critical decision that affects operational efficiency, production costs, and final product quality. This analysis provides a balanced comparison of laser cleaning and ultrasonic cleaning, drawing on established engineering principles and common industry applications. We will examine the operational mechanisms, key performance trade-offs, financial implications, and integration potential of each technology to help you select the right tool for your specific industrial challenge.

This guide aims to provide an objective, evidence-based comparison. We will analyze the total cost of ownership, compare cleaning precision and its effect on substrates, assess the environmental and safety profiles, and explore how each technology integrates into a production workflow.

High-Level Comparison: A Summary of Trade-Offs

This overview outlines how the two technologies compare across critical operational factors. The “optimal use case” highlights the scenarios where each technology’s inherent strengths are most pronounced.

|

Feature |

Ultrasonic Cleaning |

|

|

Optimal Use Case |

Selective removal of contaminants (rust, paint, oxides) from externally accessible surfaces. Excellent for in-line process integration. |

Bulk cleaning of parts with complex internal or non-line-of-sight geometries. Effective for general degreasing and particulate removal. |

|

Cleaning Mechanism |

Line-of-Sight: Uses a focused laser beam to ablate contaminants directly in the beam’s path. |

Total Immersion: Submerges parts in a fluid bath where cavitation cleans all wetted surfaces, including internal passages. |

|

Precision |

High: Can be precisely controlled to target specific areas or layers without affecting adjacent surfaces. |

Low: Cleans all submerged surfaces indiscriminately. This is a strength for overall cleaning but offers no selectivity. |

|

Substrate Impact |

Generally Low: A non-contact process. When parameters are correctly set, the substrate is unaffected. Incorrect settings can cause thermal damage. |

Variable: Risk of surface erosion or pitting from cavitation on soft metals or delicate materials. Impact also depends on the chemical harshness of the cleaning fluid. |

|

Initial Cost |

High to Very High: Significant capital investment required for the laser system and necessary safety/ancillary equipment. |

Low to Moderate: Mature technology with a wide range of equipment sizes and prices available. |

|

Operating Cost |

Low Consumables: Primary cost is electricity. No cleaning media required. Potential for High Maintenance: Laser sources have a finite life and can be expensive to replace. |

Ongoing Consumables: Continuous costs for cleaning agents, purified water, heating energy, and disposal of contaminated liquid waste. |

|

Waste Stream |

Dry particulate matter and fumes, which must be captured by a fume/dust extraction system. |

Contaminated liquid waste (water and chemicals) that requires specialized treatment and disposal according to regulations. |

|

Automation |

High Potential: Readily integrated with robotic arms for fully automated, in-line cleaning processes. |

Moderate Potential: Can be automated for batch loading/unloading and transfer, but the immersion/drying cycle often makes it an offline station. |

|

Safety |

Requires engineered controls (enclosures) and PPE for high-intensity light (laser-safe goggles). Fume extraction is mandatory. |

Requires PPE for handling chemical agents. Potential for high noise levels. Enclosures may be needed for vapor control. |

Financial Snapshot: Laser vs. Ultrasonic TCO

The core financial decision is a trade-off between upfront investment (CAPEX) and long-term running costs (OPEX).

Laser Cleaning

CAPEX: High, including the system and mandatory safety/fume extraction equipment.

OPEX: Very low, limited to electricity. Eliminates all costs for chemical consumables and liquid waste disposal.

Outlook: A front-loaded investment with a significant but predictable future cost for laser source replacement.

Ultrasonic Cleaning

CAPEX: Low, offering an accessible initial purchase price.

OPEX: High and continuous, driven by recurring costs for chemicals, heating energy, and regulated wastewater disposal.

Outlook: A pay-as-you-go model that commits the organization to perpetual operational spending.

The Bottom Line: Choose based on financial strategy—whether to absorb a high initial cost to minimize future expenses, or to lower the entry barrier at the cost of continuous operational overhead.

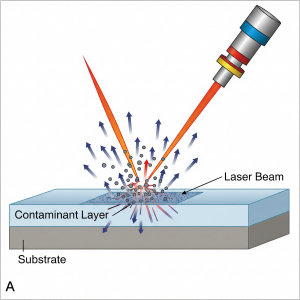

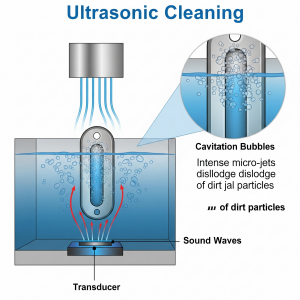

How the Technologies Work: The Physics of Cleaning

Laser Cleaning: Employs a focused beam of high-energy light in a process called laser ablation. The contaminant layer on the surface absorbs the intense energy from the laser pulse, causing it to be instantly vaporized or sublimated from the surface. The underlying substrate, which has different absorption properties, remains untouched when the laser’s wavelength, power, and pulse duration are correctly tuned.

Ultrasonic Cleaning: Utilizes transducers to generate high-frequency sound waves (typically 20−400 kHz) in a liquid bath. These sound waves create and violently collapse microscopic vacuum bubbles in a process called cavitation. The collapse of these bubbles produces powerful micro-jets of fluid that scrub surfaces, dislodging dirt, grease, and other contaminants from every wetted surface.

Application Spotlights: Where Each Technology Excels

The choice of technology is fundamentally driven by the application.

Spotlight 1: Laser Cleaning in Tire Mold Maintenance

The tire industry provides a well-documented use case for laser cleaning. In-situ cleaning of hot molds with lasers, as implemented by manufacturers like Continental AG, offers distinct advantages by eliminating the need to cool, transport, and reheat the molds. This results in reduced production downtime, extended mold lifespan by replacing abrasive methods, and improved product quality due to consistently clean mold surfaces. Here, the value of in-line automation and non-contact cleaning is paramount.

Spotlight 2: Ultrasonic Cleaning of Medical Instruments

Ultrasonic cleaning is the gold standard for cleaning complex medical and dental instruments. Devices with hinges, serrated edges, and long internal channels (cannulas) cannot be effectively cleaned by line-of-sight methods. By immersing a batch of instruments in a validated detergent solution, ultrasonic cavitation ensures that blood, tissue, and other contaminants are removed from every surface, which is a critical prerequisite for sterilization. Here, the ability to clean non-line-of-sight geometries and handle batches of complex parts is the decisive factor.

Making an Informed Choice: A Neutral Decision Framework

To determine the best solution for your needs, consider these objective questions:

1.Part Geometry: What is the physical nature of your parts? Are the surfaces to be cleaned large and externally accessible, or are they complex internal channels and intricate, non-line-of-sight features?

2.Contaminant Type: What are you removing? Is it a specific, bonded layer (e.g., paint, oxide) that requires selective removal, or is it a general, loosely adhered contaminant (e.g., oil, grease, dirt)?

3.Financial Model: What is your organization’s approach to investment? Is minimizing initial capital expenditure the priority, or can the business support a higher upfront cost to achieve potentially lower long-term operating expenses?

4.Process Integration: Does your production model benefit from an automated, in-line process with minimal downtime, or is an offline, batch-based cleaning process acceptable for your workflow?

5.Substrate Material: How sensitive is the underlying material of your part? Is it a robust metal, or is it a soft alloy, a delicate coating, or a polymer that could be damaged by harsh chemicals or cavitation erosion?

6.Environmental & Safety Priorities: What are your primary EHS concerns? Is the chief goal to eliminate chemical waste streams, or is it to manage risks associated with airborne particulates and high-intensity light?

Conclusion: Matching the Tool to the Task

Neither laser nor ultrasonic cleaning is universally superior; they are different tools designed for different tasks.

Ultrasonic cleaning remains a highly effective and mature technology, indispensable for batch cleaning of parts with complex geometries and for general-purpose degreasing where selectivity is not required.

Laser cleaning is a powerful solution for applications demanding high precision on accessible surfaces, seamless robotic integration, and the elimination of chemical consumables and their associated waste streams.

A strategic choice requires a thorough analysis of your specific part geometry, contaminant type, production philosophy, and financial model. Evaluating these factors against the distinct capabilities and limitations of each technology will lead to the most effective and economical long-term solution.

Post time: Jul-29-2025