From the QR code on a tiny automotive part to the logo on your favorite coffee tumbler, laser marking applications are an invisible yet essential part of our modern world. These permanent marks are vital for ensuring safety, tracing products through the supply chain, and adding a touch of personalized quality.

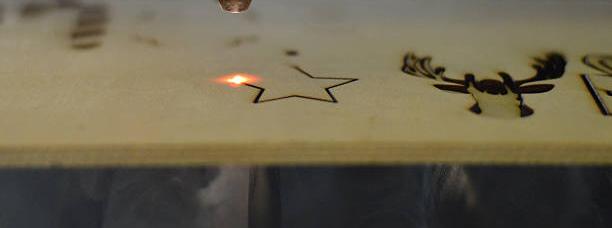

But what is laser marking? It’s a clean, non-contact process that uses a focused beam of light to create a permanent mark on a surface. The magic of this technology lies in its incredible precision, durability, and speed.

This guide will walk you through the important applications of laser marking across major industries, explain why different lasers are used for different materials, and look at the exciting future of this technology.

Top Laser Marking Applications Across Industries

The true power of laser marker is its amazing versatility. Whether in a high-tech factory or a creative workshop, its uses are revolutionizing how we identify, track, and customize products.

Industrial Applications: Marking for Traceability

In the industrial sector, a mark is more than a label—it’s a part’s permanent fingerprint. This is where industrial laser marking provides immense value.

Automotive: The auto industry depends on laser marking for absolute traceability. Part numbers, serial codes, and VINs are marked on everything from engine blocks to EV battery casings and interior dashboard buttons. These marks must survive a lifetime of heat, vibration, and corrosive fluids to allow for effective safety recalls and quality control.

Aerospace & Defense: Parts must be marked to meet stringent standards. For this reason, laser marking is a necessity. Identifiers on parts like turbine blades, structural components, and avionics must be able to withstand extreme temperatures and pressures without compromising the part’s structural integrity.

Medical Devices: When it comes to patient safety, laser marking is the gold standard. It’s used to place UDI (Unique Device Identification) codes on surgical instruments, pacemakers, and artificial joints. The resulting marks are perfectly smooth, biocompatible, and can endure countless sterilization cycles without fading or creating a surface that could harbor bacteria.

Electronics: How do you add a tracking code to a microchip smaller than your fingernail? With a beam of light. Laser marking allows for precise micro-marks on tiny, heat-sensitive components like circuit boards (PCBs) and semiconductors without causing any heat damage.

The Personal Touch: Branding and Custom Gifts

Outside the factory, laser marking adds elegance, value, and a personal touch to the products we use every day.

Promotional Products & Branding: Laser marking creates crisp, permanent branding on items like metal pens, tools, and high-end water bottles. Unlike a printed logo, a laser-marked one won’t rub off, ensuring a lasting impression.

Personalized Gifts: Customization turns an ordinary object into a treasured keepsake. Lasers can engrave intricate designs, names, and messages on jewelry, watches, phone cases, and awards, offering a level of detail and permanence that other methods can’t match.

The Right Tool for the Job: Matching Lasers to Materials

One reason laser marking is so adaptable is its ability to work on a huge range of materials, from hardened steel to delicate plastics and natural wood. This is achieved by using different types of lasers, each specialized for certain surfaces.

Fiber Lasers

The Metal and Hard Plastic Workhorse Fiber lasers are the industry standard for marking robust materials. Their intense, focused beam is ideal for creating durable marks on virtually all metals and hard plastics, making them essential for part traceability in the automotive, aerospace, and medical fields.

Best For: Stainless Steel, Aluminum, Titanium, and hard plastics like ABS.

Common Uses: Serial numbers, QR codes on parts, and logos on electronics.

CO₂ Lasers

The Organic and Non-Metal Specialist CO₂ lasers excel where fiber lasers can’t, working primarily with organic materials. Their beam is perfect for engraving wood, leather, acrylic, and glass. This makes them the top choice for personalization, branding on promotional items, and architectural signage.

Best For: Wood, Leather, Glass, Acrylic, and Stone.

Common Uses: Custom gifts, leather goods branding, and glass etching.

UV Lasers

The “Cold Marking” Expert UV lasers specialize in marking delicate, heat-sensitive materials without causing damage. Using a “cold” process that breaks molecular bonds with light instead of heat, they are crucial for marking sensitive electronics, silicon chips, and medical-grade plastics where precision is critical and thermal damage is not an option.

Best For: Heat-Sensitive Plastics, Silicon, and specialty materials.

Common Uses: Micro-marking on circuit boards and identifiers on medical tubing.

Future Outlook on Laser Marking Technologies

The world of laser marking is not standing still. Driven by the need for smaller, smarter, and more sustainable manufacturing, the technology is evolving in exciting ways. Here’s a look at what’s next:

Making Marks Tinier and More Gentle: As electronics and medical devices shrink, the marks they require must shrink too. The future lies in ultra-high-resolution marking. Using advanced lasers with incredibly short light pulses (measured in picoseconds or femtoseconds) and smarter optics, it’s becoming possible to place flawless, data-rich codes on the most delicate micro-components without leaving so much as a scorch mark.

From Mass Production to Mass Personalization: Laser markers are becoming smarter and more connected. By integrating directly with a company’s data systems, they can pull information in real time. This is key to “lot-size-of-one” manufacturing, where every item on a production line can be unique. Imagine an assembly line that engraves a custom name on one product and a unique serial number on the very next one, all without slowing down.

A Focus on Efficiency and Sustainability: Tomorrow’s lasers will do more with less. New designs are making them vastly more energy-efficient, lowering electricity costs and reducing their environmental footprint. Because laser marking uses no inks, acids, or solvents, it eliminates the need for the disposable consumables common in traditional printing. This not only saves money but also helps companies meet their environmental and safety goals, making it a clean and responsible choice.

Conclusion: A Smart Investment for Modern Business

For any modern business, laser marking is more than just a final touch—it’s a strategic investment in quality, efficiency, and brand integrity.

Whether it’s tracking a part from the factory floor to the customer, meeting strict safety regulations with permanent codes, or elevating a brand with a crisp, un-smudgeable logo, this technology provides a clear return. By eliminating the ongoing costs of inks and maintenance required by older methods, laser systems lower the overall cost of ownership while speeding up production.

Integrating advanced laser marking into your workflow is a critical step toward future-proofing your operations and securing a real competitive advantage in a demanding marketplace.

Post time: Aug-22-2025