Understanding laser cutting service pricing is essential for budgeting any project, but many people start with the wrong question: “What’s the price per square foot?” The single most important factor driving your cost is not the area of the material, but the machine time required to cut your design. A simple part and an intricate one made from the same material sheet can have vastly different prices.

The final cost is determined by a clear formula that balances material, machine time, design complexity, labor, and order quantity. This guide will break down that formula, explain each cost driver in detail, and provide actionable strategies to help you significantly reduce your project expenses.

How Every Laser Cutting Quote is Calculated

Nearly every laser cutting provider, from online platforms to local shops, uses a foundational formula to determine the price. Understanding this helps you see exactly where your money is going.

The formula is:

Final Price = (Material Costs + Variable Costs + Fixed Costs) x (1 + Profit Margin)

-

Material Costs: This is the cost of the raw material (e.g., steel, acrylic, wood) used for your project, including any material that becomes waste.

-

Variable Costs (Machine Time): This is the biggest factor. It’s the hourly rate of the laser cutter multiplied by the time it takes to complete the job. This cost changes with every design.

-

Fixed Costs (Overhead): This covers the shop’s operational expenses, such as rent, machine maintenance, software licenses, and administrative salaries, allocated to your project.

-

Profit Margin: After all costs are covered, a margin is added to ensure the business can grow and reinvest in its equipment. This can range from 20% to 70%, depending on the job’s complexity and value.

The 5 Key Drivers That Determine Your Final Price

While the formula is simple, the inputs are not. Five key factors directly influence the time and material costs that make up the bulk of your quote.

1. Material Choice: Type and Thickness Matter Most

The material you choose affects the price in two ways: its purchase cost and how difficult it is to cut.

-

Material Type: The base cost of materials varies widely. MDF is inexpensive, while high-grade aluminum or stainless steel costs significantly more.

-

Material Thickness: This is a critical cost driver. Doubling the material thickness can more than double the cutting time and cost because the laser must move much slower to cut through it cleanly.

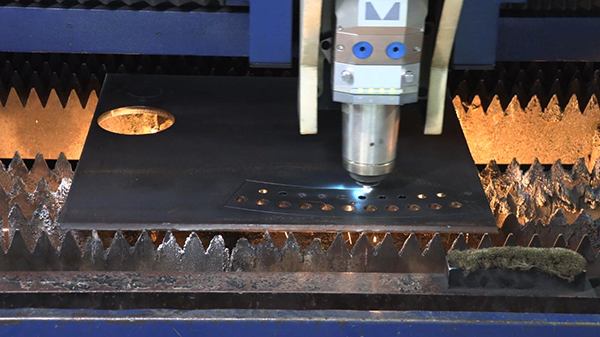

2. Machine Time: The Real Currency of Laser Cutting

Machine time is the primary service you are paying for. It is calculated based on several aspects of your design.

-

Cut Distance: The total linear distance the laser has to travel to cut your part. Longer paths mean more time and higher costs.

-

Pierce Count: Every time the laser starts a new cut, it must first “pierce” the material. A design with 100 small holes can be more expensive than one large cutout because of the cumulative time spent on piercing.

-

Operation Type: Cutting, scoring, and engraving have different costs. Cutting goes all the way through the material and is the slowest. Scoring is a partial cut that is much faster. Engraving removes material from a surface and is often priced per square inch, while cutting and scoring are priced per linear inch.

3. Design Complexity & Tolerances

Intricate designs require more machine time and precision, which increases the price.

-

Complex Geometries: Designs with many tight curves and sharp corners force the machine to slow down, increasing the total cut time.

-

Tight Tolerances: Specifying tolerances that are tighter than functionally necessary is a common source of added cost. To hold a very tight tolerance, the machine must run at a slower, more controlled speed.

4. Labor, Setup, and Post-Processing

Human intervention adds to the cost.

-

Setup Fees & Minimum Charges: Most services charge a setup fee or have a minimum order value to cover the operator’s time for loading material, calibrating the machine, and preparing your file.

-

File Preparation: If your design file has errors like duplicate lines or open contours, a technician will need to fix it, often for an additional fee.

-

Secondary Operations: Services beyond the initial cut, such as bending, tapping threads, inserting hardware, or powder coating, are priced separately and add to the total cost.

5. Order Quantity and Nesting

Volume and efficiency directly impact the per-part price.

-

Economies of Scale: The fixed setup costs are spread across all parts in an order. As a result, the cost per part decreases significantly as the order quantity increases. Discounts for high-volume orders can be as high as 70%.

-

Nesting: Efficiently arranging parts on a material sheet minimizes waste. Better nesting directly reduces your material cost.

Choosing a Provider: Automated Online Platforms vs. Local Shops

Where you get your parts made affects both the price and the experience. The two main models cater to different needs.

The “Instant Quote” Model (e.g., SendCutSend, Xometry, Ponoko)

These services use web-based software to provide a quote in seconds from a CAD file.

-

Pros: Unmatched speed and convenience, making them ideal for rapid prototyping and engineers who need immediate budget feedback.

-

Cons: Often come at a higher price. The automated systems do not catch costly design errors (like duplicate lines), and getting expert design feedback usually costs extra.

The “Human-in-the-Loop” Model (Boutique / Local Shops)

This traditional model relies on a skilled technician to review your file and provide a manual quote.

-

Pros: Access to free Design for Manufacturability (DFM) feedback that can significantly lower your costs. They can spot errors, suggest more efficient designs, and are often more flexible with customer-supplied materials.

-

Cons: The quoting process is much slower, taking hours or even days.

Which Service is Right for Your Project?

| Feature | Automated Online Service | Boutique/Local Service |

| Quoting Speed | Instant | Hours to Days |

| Price | Often Higher | Potentially Lower |

| Design Feedback | Algorithmic; Human review costs extra | Included; expert DFM advice is common |

| Ideal Use Case | Rapid Prototyping, Time-Critical Projects | Cost-Optimized Production, Complex Designs |

5 Actionable Strategies to Immediately Reduce Your Laser Cutting Costs

As the designer or engineer, you have the most control over the final price. These five strategies will help you lower costs without sacrificing function.

-

Simplify Your Design. Where possible, reduce complex curves and combine multiple small holes into larger slots. This minimizes both the cut distance and the number of time-consuming pierces.

-

Use the Thinnest Material Possible. This is the single most effective way to reduce cost. Thicker materials exponentially increase machine time. Always verify if a thinner gauge can meet your project’s needs.

-

Clean Your Design Files. Before uploading, remove all duplicate lines, hidden objects, and construction notes. Automated systems will try to cut everything, and double lines will double your cost for that feature.

-

Order in Bulk. Consolidate your needs into larger, less frequent orders. The per-unit price drops dramatically with quantity as setup costs are spread out.

-

Ask About In-Stock Materials. Choosing a material the provider already has on hand can eliminate special order fees and reduce lead times.

FAQ About Laser Cutting Prices

What is a typical hourly rate for a laser cutter?

The machine hourly rate typically ranges from $60 to $120, depending on the power and capability of the laser system.

Why is cutting metal more expensive than wood or acrylic?

Metal cutting has higher costs due to several factors: the raw material is more expensive, it requires a more powerful and costly fiber laser, and it often uses expensive assist gases like nitrogen or oxygen during the cutting process.

What is a setup fee and why is it charged?

A setup fee is a one-time charge that covers the operator’s time to load the correct material, calibrate the machine, and prepare your design file for cutting. It covers the fixed costs of starting a job, which is why it’s often absorbed into the per-part price on larger orders.

Can I save money by providing my own material?

Some local or boutique shops allow customers to supply their own material, which can be a great way to control costs. However, large automated online services rarely offer this option.

Conclusion

The key to managing laser cutting service pricing is to shift your focus from material area to machine time. The most significant savings are found not in negotiating a quote, but in designing a part that is optimized for efficient manufacturing. By understanding the cost drivers—especially material thickness, design complexity, and pierce count—you can make informed decisions that balance budget and performance.

Ready to budget your next project? Upload your CAD file to get an instant, interactive quote and see how design changes affect your price in real time.

Post time: Oct-23-2025