Modern industry is rapidly evolving, driven by an imperative for greater efficiency, precision, and sustainability. The global laser cleaning market, valued at USD 0.66 billion in 2023, is projected to reach USD 1.05 billion by 2032, growing at a CAGR of 5.34% from 2024 to 2032 (SNS Insider, April 2025). This expansion is significantly fueled by the increasing demand for non-contact, eco-friendly cleaning solutions across diverse industries, positioning industrial laser cleaning at the forefront of this evolution, demonstrating its escalating adoption and strategic importance. As a result, traditional manufacturing and maintenance methods are giving way to smarter, cleaner technologies.

Industrial laser cleaning is a non-contact technology used to treat surfaces. What was once a niche concept is now a cornerstone of advanced manufacturing. This technology uses a focused beam of light to remove contaminants. The process, known as laser ablation, offers an unparalleled level of microscopic precision.

This guide provides a definitive overview of the diverse landscape of laser cleaning application areas. We will dive immediately into the specific, high-impact applications where this technology excels—from routine laser rust removal to sophisticated surface engineering. Subsequently, we will explore the compelling business case, the fundamental science, and the future trends shaping this transformative technology. For decision-makers in high-value manufacturing hubs, understanding these practical applications is key to unlocking new levels of quality and productivity.

Core Industrial Applications of Laser Cleaning Technology

The true value of laser cleaning is demonstrated through its remarkable versatility and effectiveness across a spectrum of critical industrial tasks. Below is a detailed examination of its primary applications.

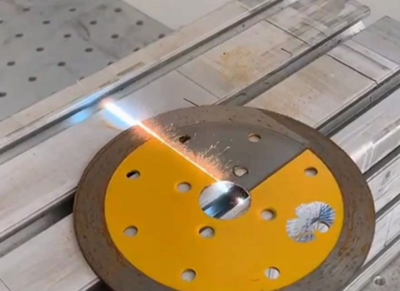

1. Laser Rust Removal and Oxide Removal

This is the most established and widespread laser cleaning application. Corrosion and oxidation are persistent challenges that compromise component integrity, hinder inspections, and cause premature failure. Laser cleaning offers a definitive solution.

Mechanism and Benefits: The laser’s energy is aggressively absorbed by the porous, hydrated structure of rust (iron oxide) and other metallic oxides (e.g., mill scale, aluminum oxide). This causes the contaminant layer to be instantly vaporized off the surface, leaving the clean, metallic substrate untouched. Unlike sandblasting, which embeds abrasive particles and induces stress, or chemical baths, which risk hydrogen embrittlement, laser rust removal is a clean, non-damaging process.

Industry Use Cases:

Manufacturing and Maintenance: Restoring corroded machine parts, high-value tooling, and dies to their original dimensional specifications, extending asset lifespan significantly.

Infrastructure and Marine: Removing heavy corrosion from bridges, structural steel, and ship hulls. The resulting pristine surface is ideal for Non-Destructive Testing (NDT) inspections and provides a superior anchor profile for new protective coatings, enhancing longevity.

Energy Sector: In power plants and oil refineries, lasers remove tough oxide layers from turbine blades and pipeline sections, a critical task for routine inspection and repair.

2. Precision Paint Stripping

Removing paint and other coatings without damaging the underlying material has historically been a significant challenge. Laser paint removal provides a level of control that is simply unattainable with other methods.

Mechanism and Benefits: By precisely tuning the laser’s power density, operators can achieve selective layer removal. This allows for the stripping of a 50-micrometer topcoat while leaving a 20-micrometer primer or e-coat layer perfectly intact. This process eliminates hazardous chemical strippers and the associated toxic waste.

Industry Use Cases:

Aerospace: This is a mission-critical application. Lasers are used to strip coatings from entire aircraft wings and fuselages for inspection and repainting. The process is safe for sensitive aluminum, titanium, and advanced composite materials, meeting stringent aviation standards.

Automotive: Paint and coating removal accounted for 34% of the laser cleaning market size in 2024, highlighting its significant adoption. In OEM production, lasers selectively remove paint from weld seams to ensure perfect electrical contact for spot welding. In restoration, they can strip paint from priceless classic cars without warping thin metal panels or damaging original metalwork.

3. High-Performance Industrial Mold Cleaning

In industries relying on molds, cleanliness is directly proportional to product quality and production efficiency. Residue buildup leads to defects and costly downtime.

Mechanism and Benefits: Lasers effectively remove a wide range of stubborn residues—including vulcanized rubber, outgassed polymers, release agents, and oils—without any physical abrasion. This protects the delicate, often mirror-polished or intricately textured surfaces of expensive molds.

Industry Use Cases:

ire and Rubber Manufacturing: Cleaning complex tread pattern molds without the wear-and-tear caused by abrasive blasting.

Plastics Injection Molding: Removing polymer residue and off-gassing buildup, ensuring flawless product finishes. A key benefit is the ability to clean molds in-situ while they are still hot, reducing maintenance downtime from hours or even days of manual cleaning to mere minutes, significantly boosting overall production efficiency.

Food and Beverage: Cleaning baking trays, vats, and food-grade molds without the risk of chemical contamination, ensuring compliance with food safety standards.

4. Advanced Surface Preparation and Pre-Treatment

The strength and reliability of a weld, adhesive bond, or protective coating depend entirely on the cleanliness of the surface. Laser cleaning provides the foundation for these processes.

Mechanism and Benefits: The laser not only removes visible contaminants but also invisible oils, greases, and thin oxide layers that can compromise adhesion. The process creates a “surface-active” state that is chemically pure and perfectly primed for the next manufacturing step.

Industry Use Cases:

Automotive and EV Manufacturing: Preparing aluminum body panels and EV battery trays for structural bonding and welding. A laser-cleaned surface ensures maximum bond strength and electrical conductivity, which is critical for vehicle safety and performance.

Medical Device Manufacturing: Preparing titanium or PEEK implants for biocompatible coatings, ensuring they bond perfectly and perform reliably within the human body.

Electronics: Cleaning contact pads on printed circuit boards (PCBs) to remove oxides and residues, guaranteeing flawless solder joints.

The Strategic Business Case: Analyzing ROI and EHS Advantages

These diverse applications are not just technically impressive; they are underpinned by a powerful and compelling business case that appeals to both engineers and financial decision-makers. The initial capital investment is offset by a dramatic reduction in Total Cost of Ownership (TCO), driven by the complete elimination of recurring costs for consumables like abrasive media, solvents, and cleaning agents. Case studies often demonstrate ROI achieved within 6-18 months for mid-range systems (Baison Laser), with overall operational cost reductions reported due to eliminating consumables and significantly reducing labor. Furthermore, a significant reduction in manual labor, coupled with the potential for full automation, leads to enhanced productivity and throughput.

From a risk management perspective, the technology’s EHS (Environmental, Health, and Safety) profile is unmatched. It helps organizations meet and exceed stringent environmental regulations by eliminating hazardous waste streams and VOC emissions. Stringent environmental regulations, particularly in Europe and North America, are identified as a significant driver for market growth. It also creates a fundamentally safer workplace by removing risks associated with chemical exposure and airborne abrasive particulates, as operators avoid contact with harmful chemicals or the inhalation of fine particles generated by abrasive methods.

Key Considerations and Disadvantages

While the benefits are compelling, a balanced assessment requires acknowledging the potential disadvantages of laser cleaning technology.

High Initial Capital Investment: The upfront cost of industrial-grade laser cleaning systems is significantly higher than that of traditional equipment like sandblasters or chemical baths, which can be a barrier for some organizations. For example, high-power systems (above 1 kW) can cost between USD 300,000 to USD 500,000.

Strict Safety Protocols: Operating high-power lasers safely requires a controlled environment. This includes implementing stringent safety measures such as laser-safe enclosures, specialized eye protection for operators, and robust fume extraction systems to manage the hazardous particulates generated during ablation. Compliance with regulatory bodies like OSHA in the U.S. and adherence to standards such as IEC 60825 are mandatory, often requiring significant investment in advanced safety measures and mandatory training.

Processing Speed and Scale: For removing simple contaminants over very large, non-critical surface areas, traditional methods like grit blasting can sometimes be faster. The primary advantage of laser cleaning lies in its precision and delicacy, not always in raw speed for bulk material removal.

Line-of-Sight Limitation: Laser cleaning is a light-based process and requires a direct line of sight to the surface. Cleaning complex geometries with deep cavities, internal channels, or shadowed areas can be difficult or impossible without advanced robotics or repositioning the part.

The Fundamental Principles of Laser Ablation Technology

The science that enables these applications is known as laser ablation. It functions by delivering highly concentrated energy in extremely short pulses. The targeted contaminant absorbs this energy, is instantly heated past its vaporization point, and transforms into a plasma plume that is ejected from the surface. The underlying substrate, which has a different absorption property at the laser’s wavelength, remains unaffected. This entire process is controlled by precise parameters—such as laser power, pulse frequency, and scan speed—allowing it to be tailored perfectly for each unique laser cleaning application.

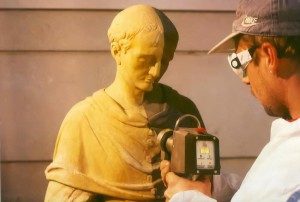

Beyond the Factory Floor: Niche and Emerging Applications

The unique attributes of laser cleaning have also been adopted in highly specialized fields. In cultural heritage, it is used by museum conservators to clean priceless artifacts without physical contact. In archaeology, it uncovers delicate details on ancient finds. In the biomedical sector, it ensures the pristine cleanliness of medical implants and surgical tools.

The unique attributes of laser cleaning have also been adopted in highly specialized fields. In cultural heritage, it is used by museum conservators to clean priceless artifacts without physical contact. In archaeology, it uncovers delicate details on ancient finds. In the biomedical sector, it ensures the pristine cleanliness of medical implants and surgical tools.

Next-Generation Laser Cleaning: AI, Portability, and Higher Power Systems

The technology continues to advance, with trends pointing towards AI-driven process controls for real-time adjustments, higher-power systems for large-scale infrastructure projects, and increasingly compact, portable systems for field maintenance and repair work.

Conclusion

Laser cleaning has transcended its status as a niche technology to become a strategic industrial platform. Its versatility across a wide range of applications—from foundational laser rust removal to the most delicate surface removal—provides a powerful tool for any organization committed to achieving the highest standards of quality, efficiency, and sustainable operation.

Ready to see how laser cleaning can transform your operations? Contact our experts today to discover the perfect solution for your needs.

Post time: Jul-25-2025