Your laser welding machine is a powerful asset and a significant investment. But unexpected downtime, inconsistent performance, and premature failure can turn that asset into a major liability. The cost of replacing a laser source or critical optics can be staggering.

What if you could significantly extend its productive life, ensuring consistent quality and maximizing your return on investment? It’s not about luck; it’s about strategy. This guide provides a comprehensive framework for extending your laser welding machine’s lifespan, covering everything from daily maintenance to long-term strategic planning.

Key Takeaways

Average Lifespan: A well-maintained machine typically lasts 10,000 to 30,000 hours, but this can be significantly extended with proper care.

Core Pillars of Longevity: The machine’s life depends on four key areas: its Working Environment, Usage Patterns, Maintenance Rigor, and Operator Skill.

Biggest Threats to a Laser Welder: The primary enemies of your machine are excessive heat, dust, high humidity, unstable power, and consistent operation beyond its rated capacity.

What Is the Average Lifespan of a Laser Welding Machine?

A well-maintained laser welding machine generally has an estimated service life of 10,000 to 30,000 hours of operation. However, this is a broad estimate. As we’ve discussed, factors like meticulous maintenance and optimal environmental conditions can significantly influence whether your machine performs at the lower or higher end of this range—or even substantially exceeds it.

Thanks to advancements in technology, many modern, high-quality fiber laser sources themselves boast impressive lifespans of around 100,000 hours. But the overall machine’s longevity depends on the synergistic health of all its integrated components, not just the source.

6 Factors That Directly Impact Machine Longevity

Understanding the underlying stressors empowers you to implement the most effective preventive measures.

1. The Working Environment

Sensitive electronics and delicate optics are highly susceptible to their surroundings.

Temperature & Humidity: Extreme temperatures stress components, while high humidity can cause corrosive condensation. For instance, a sudden drop in temperature can cause condensation on internal optics, leading to permanent damage.

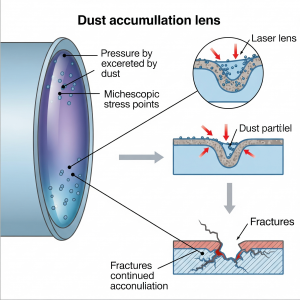

Cleanliness: Dust and airborne debris are silent assassins. They can settle on lenses, causing the laser beam to lose power, or block cooling fins, leading to overheating and component failure.

2. Frequency of Use and Operational Load

How intensively you use the machine directly influences its wear rate.

Excessive Use: Running a machine constantly without adequate breaks leads to significant thermal stress and accelerated wear on the laser source and cooling system.

Excessive Loads: Consistently operating at or near maximum capacity puts immense mechanical stress on moving parts. This is why understanding your machine’s duty cycle—the maximum operating time at a given output power—is crucial.

3.Electronic Component Stability

The operational reliability of the laser welding system is intrinsically linked to the stability of its electronic components. The control boards, power supplies, and driver circuits are subject to degradation from several factors that can directly impact performance, precision, and system lifespan.

Thermal Stress: Thermal cycling and sustained heat induce stress on solder joints and accelerate the degradation of components like capacitors, compromising system stability and power regulation.

Component End-of-Life: All components have a finite lifespan. Inevitable material degradation leads to performance drift, intermittent faults, and eventual system failure, requiring a proactive replacement strategy.

4.Unstable Electrical Power

Your laser welder’s sensitive electronics are defenseless against an unstable power supply. Power surges, sags, and other electrical fluctuations can wreak havoc on control boards and the power source, leading to sudden failures or latent damage that shortens their lifespan. Providing a dedicated, professionally conditioned power line isn’t an optional extra—it’s a fundamental requirement to protect your asset and ensure reliable operation.

5.Adopt a Proactive Maintenance Strategy

A “fix it when it breaks” approach is one of the fastest ways to shorten your welder’s life. A structured, proactive maintenance plan is designed to catch and resolve minor issues, like a dirty filter or a worn seal, before they can cascade into a catastrophic failure. This foresight not only prevents expensive, emergency repairs and unscheduled downtime but also significantly lowers the machine’s total cost of ownership over its lifetime.

6.Operator Skill and Discipline

Even the most robust machine is vulnerable to human error. An operator who consistently uses incorrect parameters, ignores system alerts, or mishandles delicate optical components can directly cause accelerated wear or even immediate damage. Proper operational discipline and adherence to Standard Operating Procedures (SOPs) are critical. Comprehensive training turns your operators into the first line of defense, empowering them to run the machine efficiently and safely while maximizing its service life.

A Step-by-Step Guide to Extending Your Laser Welder’s Lifespan

Step 1: Create an Optimal Working Environment

Control Temperature & Humidity: Maintain a stable environment, typically between 15℃and 30℃ (59℉and 86℉), with relative humidity below 70%.

Ensure Air Purity: Implement robust ventilation and consider advanced air filtration systems, especially in industrial settings, to protect optical components and electronics from dust.

Step 2: Implement Strategic Usage Planning

Avoid Constant High-Power Operation: Allow for planned cooldown periods or stagger high-intensity tasks to reduce thermal stress. Think of it like redlining a car engine—it’s not designed for sustained peak performance.

Operate Within Rated Capacity: Always respect the machine’s designed parameters and duty cycle to prevent excessive stress on mechanical and electrical parts.

Step 3: Commit to a Rigorous Maintenance Schedule

Routine Cleaning & Lubrication: Regularly clean optical components (lenses, mirrors) with approved solutions and lubricate moving parts (guide rails, bearings) to minimize friction.

Proactive Component Replacement: Don’t wait for parts to break. Establish a schedule to replace vulnerable consumables like filters and seals based on manufacturer recommendations. The cost of routinely replacing a consumable part, whether it’s an optical window or a water filter, is minuscule compared to the cost of the catastrophic failure it is designed to prevent.

Step 4: Invest in Operator Training and Expert Support

Thorough Operator Training: Skilled operators who understand the machine’s capabilities, proper parameter settings, and basic troubleshooting are invaluable. They minimize stress on the machine and prevent accidental damage.

Leverage Expert Maintenance: For complex diagnostics, calibration, and repairs, rely on professional technicians. Regular professional servicing can identify subtle issues before they become major problems.

Step 5: Consistently Monitor Machine Health

Implement Performance Monitoring: Use available tools to track key health indicators like actual laser power output, chiller temperature stability, and error codes. Many modern machines offer IoT-enabled diagnostics for predictive maintenance.

Establish Rapid Fault Diagnosis: Create a clear system for identifying and addressing problems promptly. Quick action can stop issues from cascading into more serious damage and extended downtime.

Step 6: Plan for Strategic Updates and Upgrades

Stay Current with Technology: Software updates can improve efficiency and performance, sometimes extending component life through optimized control algorithms.

Evaluate Equipment Upgrades: There comes a point when upgrading an older machine is more cost-effective than continuous repairs. Consider this when maintenance costs become prohibitive or newer technology offers a substantial ROI.

Conclusion: Protect Your Investment for Years to Come

Extending the service life of your laser welding machine isn’t about a single magic bullet; it’s about adopting a comprehensive, proactive strategy. By meticulously controlling its operating environment, planning its usage thoughtfully, committing to rigorous maintenance, and ensuring your operators are highly skilled, you can maximize your investment, drastically reduce costly downtime, and ensure your machine delivers high-quality results for many productive years.

Frequently Asked Questions (FAQ)

Q1: How often should a laser welder be serviced?

A: This depends on usage and the operating environment. A general rule is to follow the manufacturer’s recommended service intervals. Daily visual checks by the operator are essential, with a more thorough professional service conducted quarterly, semi-annually, or annually.

Q2: What is the most expensive part to replace on a laser welding machine?

A: The laser source is typically the most expensive single component, often accounting for a significant portion of the machine’s total cost. This is why protecting it from overheating and contamination is paramount.

Q3: Can dust really damage a laser welder?

A: Absolutely. Dust settling on a focusing lens or mirror can absorb laser energy, causing it to heat up and crack, burn, or shatter. This permanently damages the optic and severely degrades the machine’s performance.

Q4: Does running a laser at lower power extend its life?

A: Yes. Consistently running any machine well below its maximum rated capacity reduces thermal and electrical stress on all components, especially the laser source and power supply, which can contribute to a longer operational lifespan.

Need help creating a maintenance plan for your equipment? Contact our expert service team today for a consultation.

Post time: Jul-29-2025