Choosing between a handheld and a robotic laser welder is a pivotal decision that will define your operational strategy. This isn’t merely a choice between tools; it’s an investment in a production philosophy. The right answer depends entirely on your primary business objective: Do you need unparalleled flexibility for custom work, or do you require the uncompromising speed and precision of automated mass production?

This guide provides a clear framework to help you make the best strategic investment for your company’s future.

The Short Answer: Flexibility vs. Scale

Handheld Laser Welders are the definitive choice for job shops, repair services, and custom fabricators. If your daily work involves a high mix of different parts, low-volume production runs, or large, cumbersome workpieces, the agility of a handheld system is essential.

Robotic Laser Welders are purpose-built for high-volume, repeatable manufacturing. If your business model relies on speed, perfect consistency, and scaling up production for industries like automotive, aerospace, or medical devices, a robotic system is the necessary path forward.

At a Glance: Handheld vs. Robotic System

|

Feature |

Handheld Laser Welder |

Robotic Laser Welder |

|

Best For |

Custom fabrication, prototypes, repairs, large & awkward parts. |

High-volume, high-repetition production lines. |

|

Core Advantage |

Ultimate Flexibility & Portability |

Unmatched Speed, Precision & Repeatability |

|

Precision |

High, but dependent on operator skill. |

Extremely high and perfectly consistent. |

|

Speed |

Fast for single jobs. |

24/7 operation. |

|

Initial Cost |

Low to Medium |

High |

|

Operator Role |

Skilled hands-on operator. Easy to learn basics, difficult to master. |

Highly skilled programmer and system technician. |

|

Job Changeover |

Instantaneous |

Can be time-consuming and requires reprogramming. |

The Case for Flexibility: When to Choose a Handheld Laser Welder

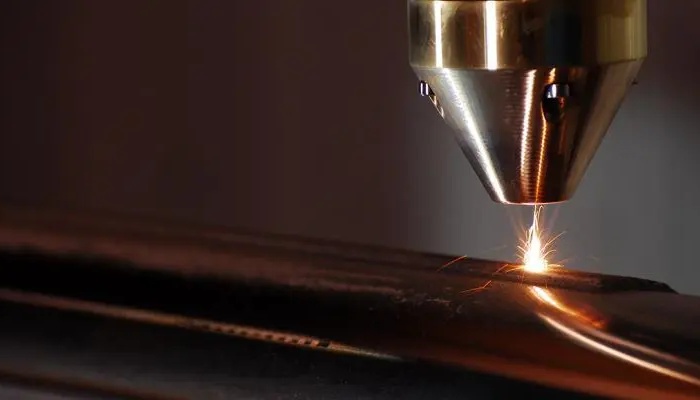

A handheld laser welder empowers a skilled operator with precision and power, making it the champion of agility in a modern workshop. It is the optimal choice when your business model is built on versatility.

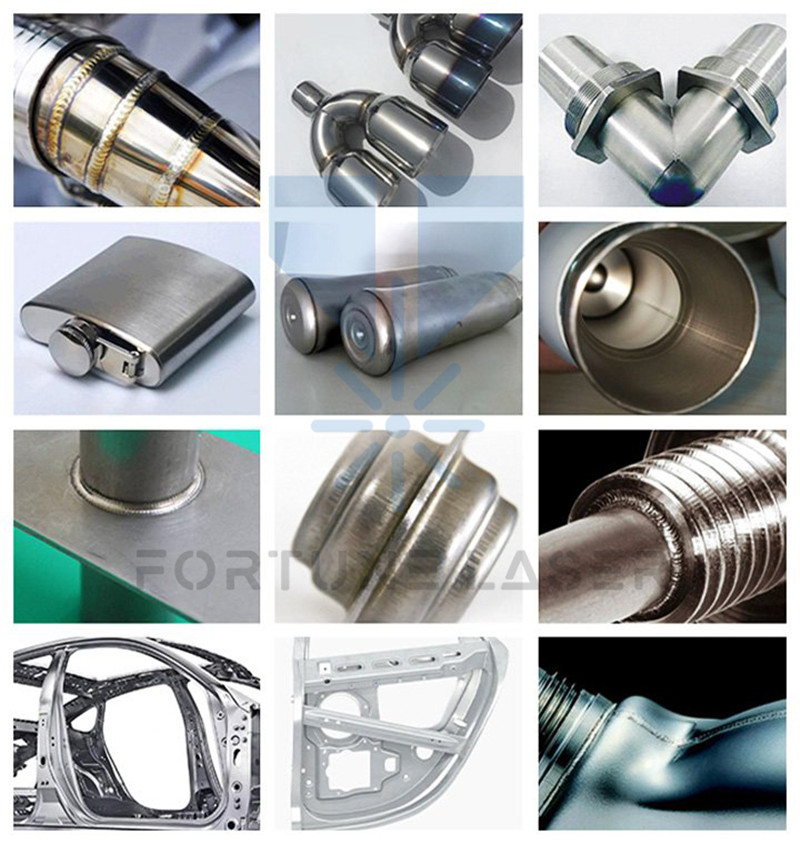

High-Mix, Low-Volume Production: Handheld systems are the backbone of job shops where every project is different. An operator can switch from welding a custom stainless steel countertop to repairing a complex mold or fabricating a prototype with zero technical changeover time.

Large or Complex Geometries: The freedom of a handheld torch is indispensable when working on parts that cannot fit into a fixed robotic enclosure. This includes large-scale projects like industrial tanks, custom vehicle chassis, or architectural metalwork.

On-Site Repair and Installation: The portability of many handheld units allows you to bring the welding capability directly to the job site. This is a game-changer for repairing heavy machinery in place or performing architectural installations, minimizing client downtime and logistical challenges.

The Case for Scale: When to Choose a Robotic Laser Welder

A robotic laser welder is more than a tool—it’s an integrated production system designed for industrial-scale output. It is the engine for manufacturers who prioritize efficiency, consistency, and volume.

Uncompromising Precision and Repeatability: For industries where failure is not an option, robotic systems are essential. By eliminating human variability, they deliver identical, flawless welds every time. This is critical for medical implants, aerospace components, and sensitive electronic enclosures.

Maximum Speed: A robot is engineered for relentless, 24/7 “lights-out” manufacturing. It works without breaks or fatigue, dramatically reducing cycle times and maximizing output, which is crucial for high-volume supply chains like automotive (EV battery trays, frames) and consumer electronics.

Superior Weld Integrity: A robot can perfectly maintain the optimal torch angle, travel speed, and standoff distance, which is physically impossible for a human operator to do consistently. This results in stronger, deeper, and more uniform welds with better metallurgical properties.

The Deeper Dive: Financial and Technical Realities

To make a truly informed decision, you must look beyond the initial quote and analyze the total financial and operational impact.

Understanding the Total Cost of Ownership (TCO)

The sticker price is just the beginning. The TCO provides a complete picture of an asset’s cost over its lifetime, revealing its true profitability.

1.Initial Investment (Capital Expenditure – CapEx)

This is the most obvious financial difference.

Handheld Welder: This is a lower-cost entry into laser welding, as you are essentially purchasing a standalone tool. The price primarily includes the laser power source and the handheld welding head. This significantly lower upfront cost makes it an accessible option for smaller shops, startups, or businesses with limited capital budgets looking to add a new capability.

Robotic Welder: This is a major capital investment because you are purchasing a complete, integrated production system. The cost is substantially higher as it includes not just the laser source, but also a multi-axis robotic arm, a mandatory light-tight safety enclosure, custom part fixtures, and the complex engineering required to program and integrate all components for your specific part. This makes it a significant financial decision suited for dedicated, high-volume manufacturing.

2.Operational Costs (Operating Expenditure – OpEx)

These ongoing expenses are critical for long-term profitability.

Labor: This is the key differentiator. A handheld system requires a dedicated operator for every minute it is running. A robotic cell, once programmed, can operate with minimal supervision, drastically reducing the labor cost per part.

Consumables & Utilities: Both systems use shielding gas, nozzles, and electricity. However, a robotic system running continuously at high power will naturally have higher consumption rates than a handheld welder used intermittently.

3.Return on Investment (ROI) and the “Crossover Point”

This calculation determines when the more expensive machine becomes the more profitable one.

For low-volume work, a handheld welder’s low entry cost makes it more profitable.

As production volume rises, a “crossover point” is reached where the cumulative savings in labor from a robotic system surpass its high initial investment. Beyond this point, every part made on the robotic line is substantially more profitable. You must accurately forecast your production volume to determine if you can reach this crossover point in a reasonable timeframe.

Material Compatibility and Power Requirements

A key advantage of modern fiber lasers—both handheld and robotic—is their ability to weld a wide variety of metals, including:

Stainless Steel Carbon Steel Aluminum Copper Titanium

The crucial factor is matching the laser power to the material type and thickness. A 1 kW to 1.5 kW laser is excellent for thinner gauge metals, while thicker sections, especially for reflective metals like aluminum and copper, require higher power in the 2 kW to 3 kW range or more for optimal speed and penetration.

Conclusion: Making Your Suitable Choice

The decision between a handheld and robotic laser welder is a strategic trade-off between Flexibility and Repeatability.

Choose Handheld if: Your business is defined by variety, custom work, and agility. You need to adapt quickly to different jobs and manage your initial capital investment carefully.

Choose Robotic if: Your business is focused on scaling up the production of a specific set of parts. Your primary goals are achieving maximum speed, flawless consistency, and reducing long-term labor costs.

By carefully analyzing your part complexity, production volume, budget, and long-term business goals, you can make a powerful investment that will drive your company’s efficiency, quality, and growth for years to come.

Post time: Aug-04-2025