The application of a fiber laser cutting machine in the construction industry represents a significant step forward in how metal components are fabricated. As architectural designs become more complex and project schedules tighten, the demand for greater precision and efficiency has grown. Fiber laser cutting directly addresses this need by translating digital blueprints into physical parts with exceptional accuracy. This guide explores its core applications, workflow, and the practical considerations for its adoption.

Core Applications in Detail: From Structure to Facade

Fiber laser cutting is not a single-use technology; its value is demonstrated across the entire building lifecycle, from the foundational structure to the finest architectural details.

Structural Steel Fabrication

The steel skeleton of a building is its most critical element, where precision is paramount for safety and stability. Fiber lasers are used to make highly accurate cuts on primary structural components.

What it is: This includes cutting heavy-duty materials like I-beams, columns, and channels. More importantly, it involves creating complex features on these parts, such as coping (shaping the end of a beam to fit against another), notching, and creating intricate bolt-hole patterns.

Why it matters: In traditional fabrication, creating these connections is a multi-step, labor-intensive process. A fiber laser can perform all these cuts in a single, automated operation. Perfectly aligned bolt holes mean that steel beams connect on-site without forceful alignment or re-drilling—a common source of costly delays. Furthermore, the laser produces a clean, slag-free edge that is ideal for high-strength welding, as it eliminates impurities that could otherwise compromise the joint’s integrity.

Precision Fabrication for MEP and HVAC Systems

A building’s mechanical, electrical, and plumbing (MEP) systems are complex networks hidden within the walls and ceilings. The performance of these systems often depends on the quality of their components.

What it is: This goes beyond simple ductwork. Lasers fabricate precise flanges, fittings, hangers, mounting brackets, and custom enclosures for electrical panels and control systems.

Why it matters: Think of a building’s HVAC system as its lungs. Laser cutting ensures every component is made with airtight precision. Even tiny gaps in traditionally made ducts add up, causing the system to work harder and waste energy. Laser-cut components fit together seamlessly, minimizing air leakage and reducing the building’s long-term energy consumption. This level of precision is crucial for meeting modern green building standards.

Architectural and Ornamental Metalwork

Fiber lasers give architects a powerful tool to realize creative and ambitious designs that were once impractical or unaffordable.

What it is: This technology is behind many modern architectural features, such as perforated building skins that create patterns of light and shadow, brise-soleil sunscreens that help cool buildings, custom staircase stringers, and ornate gate designs.

Why it matters: Previously, creating a complex pattern in a steel panel was a difficult, multi-stage process. A fiber laser can etch and cut an entire intricate design—like a floral pattern for a decorative screen or a corporate logo for a building entrance—directly from a digital file in a single pass. This streamlines the process, making highly customized architectural elements more accessible for a wider range of projects.

Prefabrication and Modular Construction

In off-site construction, the entire building is manufactured in a factory as a series of modules or panels. This process lives or dies by precision.

What it is: Lasers are used to cut every component to exact dimensions, including wall frames, floor cassettes, interlocking joints, and precise openings for windows and doors.

Why it matters: Off-site construction is vulnerable to “tolerance stacking”—where tiny inaccuracies in each part accumulate, leading to major alignment problems when modules are assembled. Because fiber lasers work with tolerances often smaller than the width of a human hair, they virtually eliminate this issue. This guarantees that when modules arrive on site, they fit together exactly as intended, enabling faster, more predictable, and higher-quality construction.

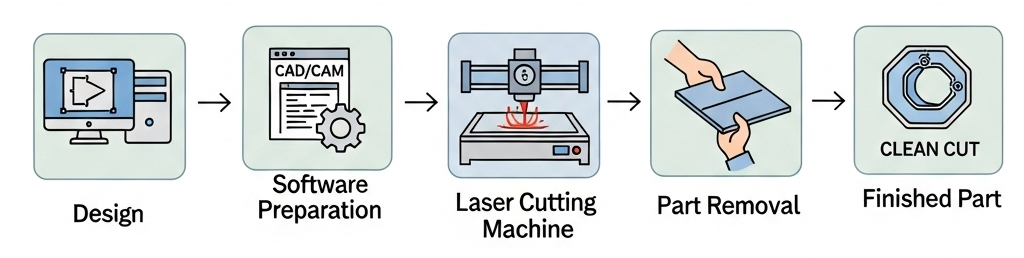

The Fundamental Workflow

A fiber laser cutting machine is a powerful tool that creates a direct and highly accurate link between a design plan and the finished metal part. This capability ensures that the final product perfectly matches the original idea, leading to better quality construction.

The Cutting Process

The Plan: The process begins with a detailed design for a metal part. This plan specifies its exact shape, the type of metal to be used, and its precise thickness.

Efficient Layout: To avoid wasting material, the shapes of all the different parts are arranged cleverly across a raw sheet of metal, like pieces of a puzzle. This smart arrangement makes the most of every sheet, which significantly cuts down on scrap metal, saving money and resources.

Precision Cutting: Once the layout is loaded, the operator starts the machine. Guided by the plan, the fiber laser directs an intense beam of light to make the cuts. The machine’s great precision ensures it follows the intended path perfectly, which removes the errors that can happen when parts are measured and cut by hand.

Key Things to Consider

Adopting this technology requires careful thought about its requirements and capabilities.

The Investment

While the initial cost of a fiber laser cutter is significant, it pays for itself over time. The savings come from multiple areas:

Reduced Labor: Less manual work is needed to cut and finish parts.

Less Wasted Material: The smart layout process minimizes expensive scrap metal.

Faster Production: The machine works quickly and continuously.

Fewer Mistakes: Extreme accuracy means fewer costly errors and delays on the job site.

Knowing the Limitations

A fiber laser is not the perfect solution for every task. For cutting extremely thick steel, other methods may be more cost-effective. Additionally, highly reflective metals like untreated copper or aluminum can be challenging for the laser and may require special techniques to cut cleanly. It’s about using the right tool for the right job.

The Human Element

Operating a modern laser cutter is a skilled technician’s job. The operator programs the machine with the cutting plan, performs quality checks on the finished parts, and is responsible for maintaining the machine’s sensitive optics. This role requires a combination of mechanical aptitude and technical skill. Due to the power of industrial lasers, thorough safety training is absolutely essential.

Conclusion: Building with Confidence

Ultimately, the fiber laser cutting machine is about providing a reliable method to turn a design into a physical reality. It produces metal components with unmatched precision, ensuring that what is planned is exactly what gets built. By boosting accuracy, reducing waste, and enabling more complex designs, this machine is a vital tool for modern construction.

Post time: Aug-28-2025