Lowest Price for Mould Laser Welding Machine - Integrated All in One Handheld Laser Welding Machine – Fortune

Lowest Price for Mould Laser Welding Machine - Integrated All in One Handheld Laser Welding Machine – Fortune

Lowest Price for Mould Laser Welding Machine - Integrated All in One Handheld Laser Welding Machine – Fortune Detail:

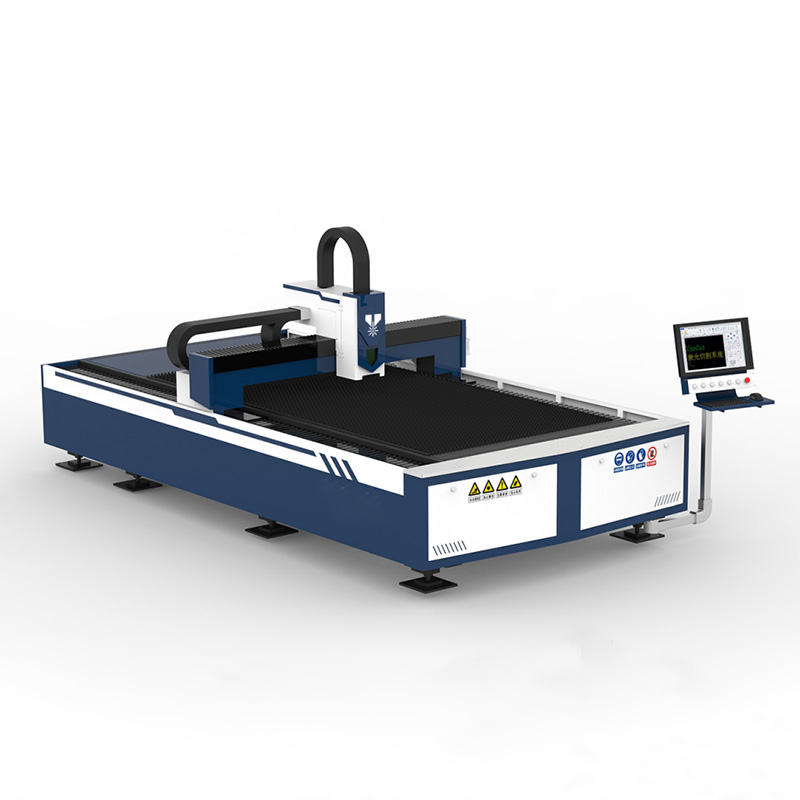

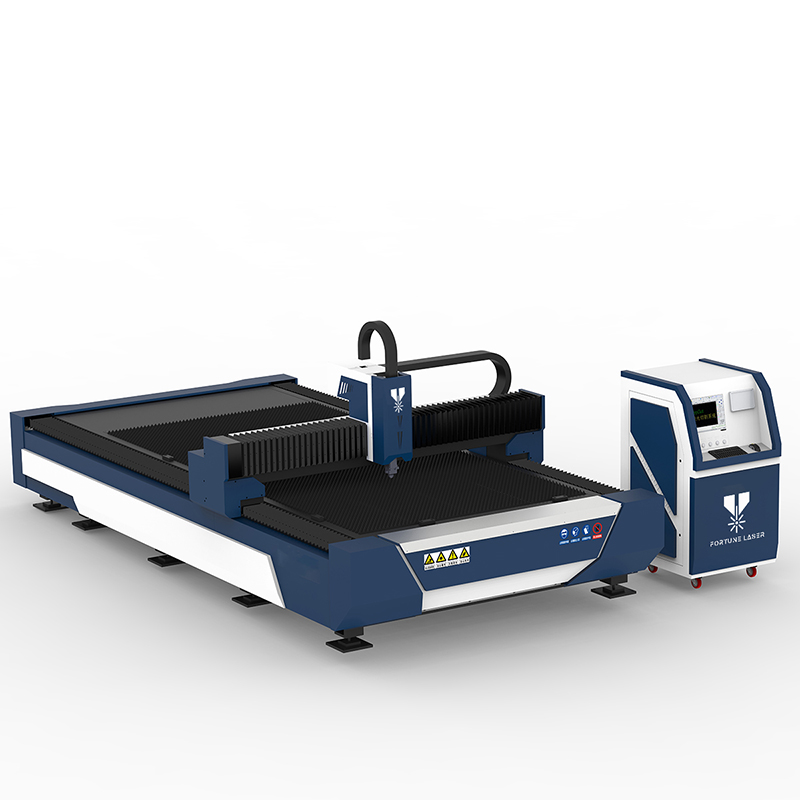

Integrated All in One Handheld Laser Welding Machine

Integrated All-in-One Handheld Laser Welding Machine from Fortune Laser Technology Co., Ltd., a high-tech solution designed to transform your welding, cutting, and cleaning tasks. This versatile, all-in-one device combines advanced laser technology with a user-friendly design, making it a powerful tool for a wide range of applications, from industrial manufacturing to household projects.

Why Choose Our Laser Welder?

Exceptional Performance: Our handheld laser welder uses a 1000–2000 watt fiber laser to deliver high electro-optical conversion efficiency and superior beam quality, resulting in more uniform weld spots and deeper penetration. It’s especially effective for welding ultra-thin parts that are typically difficult to work with using traditional methods like argon arc welding.

Maintenance-Free Operation: Say goodbye to frequent adjustments and high operational costs. Our machine is designed to be maintenance-free, with low power consumption and no consumables, which significantly reduces long-term processing costs.

User-Friendly Design: The compact and highly integrated design, complete with built-in air cooling, makes it flexible and easy to use. The operation is so simple that you don’t need to be an experienced technician to get started.

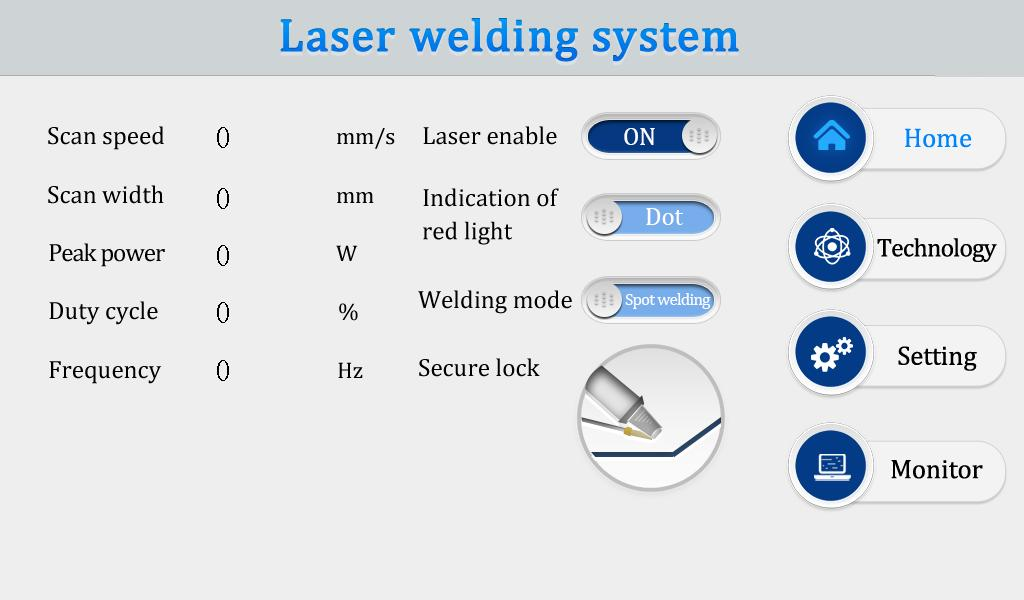

Enhanced Safety: The machine features a safety protection upgrade that restricts laser emission to metal surfaces only. For additional security, a safety ground lock requires the welding head to be in contact with the workpiece before the laser can be activated, preventing accidental light output and potential injury.

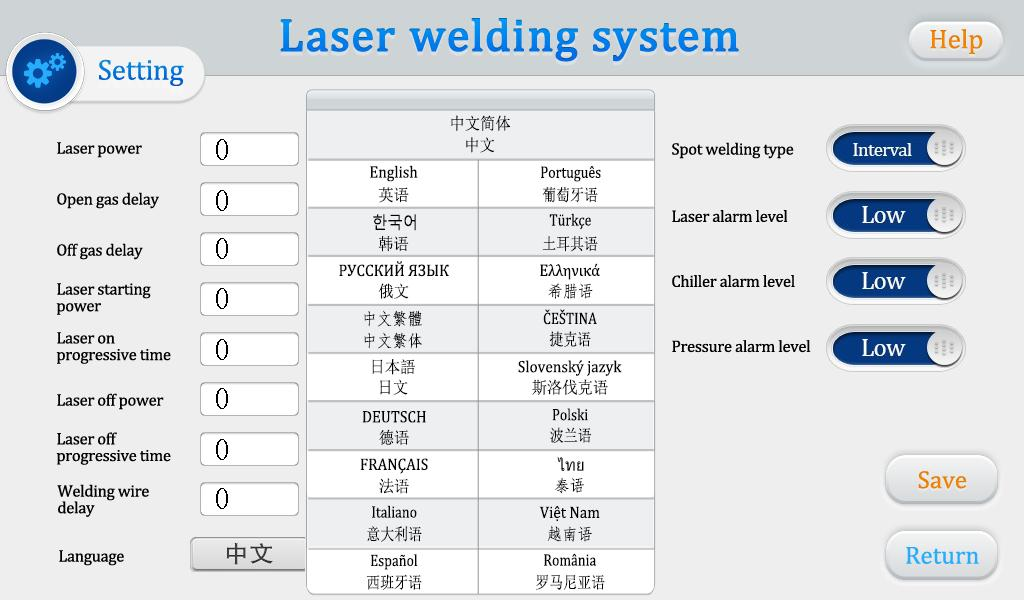

Global Accessibility: Our intuitive interface supports more than 20 languages, making the machine accessible to a global workforce and enabling seamless operation for users worldwide.

Product Parameters

| Parameter Category | Parameter Name | Details & Specifications |

| Laser & Performance | Laser Type | 1000–2000 watt fiber laser |

| Electro-Optical Efficiency | High conversion efficiency | |

| Beam Quality | Superior, fiber-transmitted | |

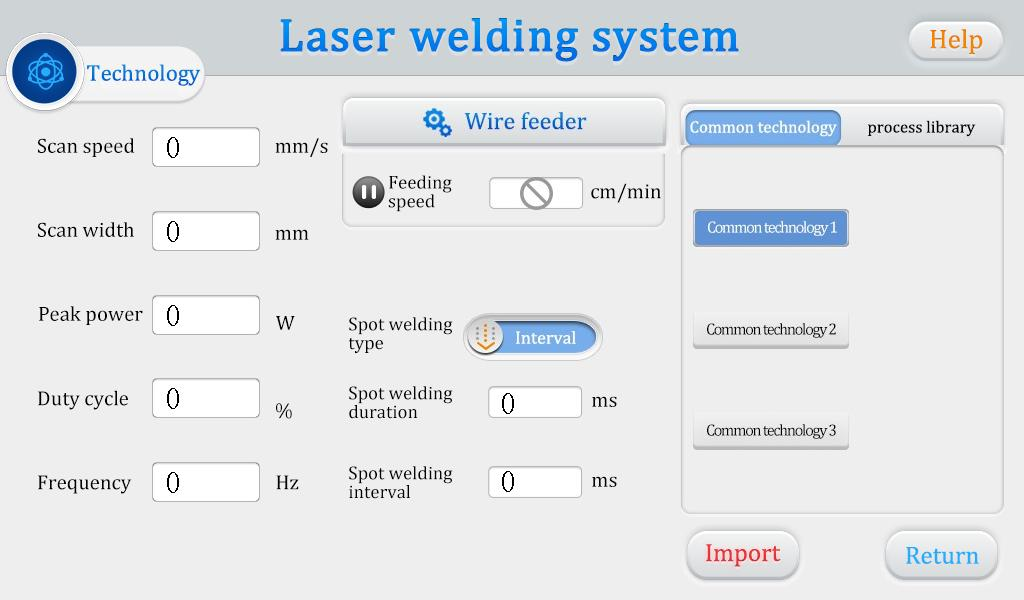

| Oscillation Amplitude | 0mm to 6mm, adjustable via PLC control system | |

| Scan Speed (Welding) | 2–6000 mm/s (common speed is 300 mm/s) | |

| Scan Width (Welding) | 0–6 mm (common width is 2.5–4 mm) | |

| Peak Power | Must be less than or equal to the laser power on the settings page | |

| Duty Cycle | 0–100% (default: 100%) | |

| Pulse Frequency | Recommended range: 5–5000 Hz (default: 2000 Hz) | |

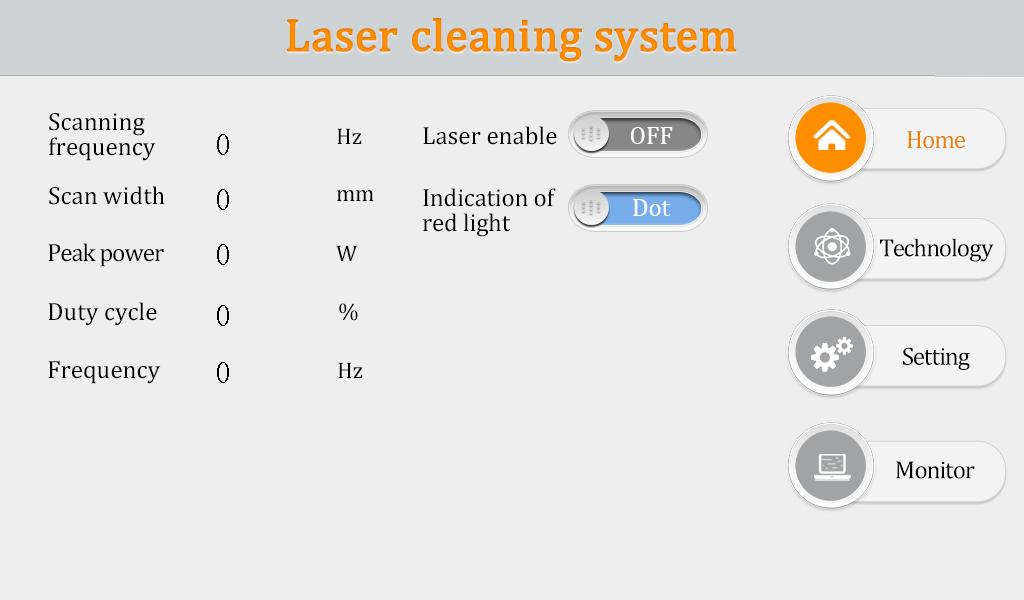

| Operational Modes | Supported Modes | Welding, Cutting, and Cleaning |

| Welding Modes | Continuous and Spot welding | |

| Scan Width (Cleaning) | 0–30 mm (with F150 focusing lens) | |

| Electrical & Environment | Power Supply | 220VAC ±10%, 6kW total power |

| Power Breaker | Requires a C32 air circuit breaker with leakage protection | |

| Workroom Temperature | 0°C to 40°C | |

| Workroom Humidity | <60%, non-condensing | |

| Power Status Monitoring | Displays 24V, ±15V supply voltages and currents | |

| Safety Features | Laser Emission | Restricted to metal surfaces only |

| Safety Ground Lock | Requires the welding head to be in contact with the workpiece for laser activation | |

| Class | Class 4 laser product | |

| Safety Warnings | Warns of high voltage, laser radiation, and fire hazards | |

| Design & Usability | Handheld Head | Equipped with a 10-meter imported optical fiber |

| Design | Compact and highly integrated, with built-in air cooling | |

| Interface Languages | Supports 19 languages in the standard version | |

| User Skill Level | Simple to operate; no experienced technician required | |

| Maintenance | Cleaning | Wipe external components, protective lens, and keep the environment dust-free |

| Cooling System | Regularly inspect and clean dust from the air duct | |

| Wearing Parts | Protective lens and copper nozzle | |

| Maintenance Frequency | Daily and half-yearly checks recommended |

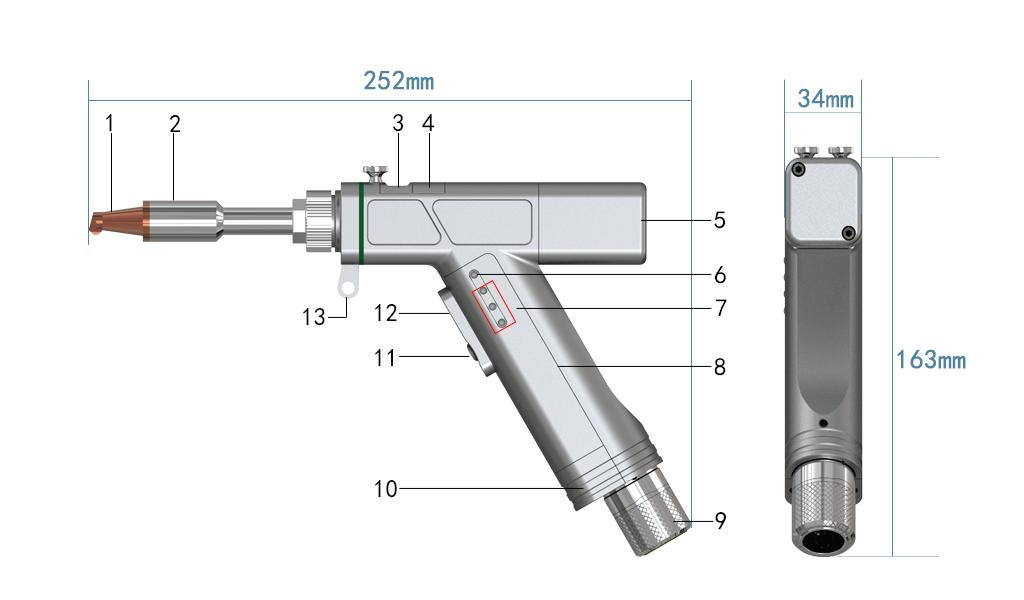

Laser Welding Head

1- Copper nozzle 2- Graduated tube 3- Protective mirror

4- Focusing lens 5- Motor 6- Status indicator 7- Process indicator light

8- Collimating mirror 9-QBH 10-trachea 11- Light output switch button

12- Process switch button 13- Wire feeding support

Home Page

Product detail pictures:

Related Product Guide:

To create far more benefit for customers is our company philosophy; customer growing is our working chase for Lowest Price for Mould Laser Welding Machine - Integrated All in One Handheld Laser Welding Machine – Fortune , The product will supply to all over the world, such as: France, Swedish, Slovak Republic, We have been persisting in the business essence "Quality First, Honoring Contracts and Standing by Reputations, providing customers with satisfying goods and service. " Friends both at home and abroad are warmly welcome to establish everlasting business relations with us.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!