Integrated All in One Handheld Laser Welding Machine

Integrated All in One Handheld Laser Welding Machine

Integrated All in One Handheld Laser Welding Machine

Integrated All-in-One Handheld Laser Welding Machine from Fortune Laser Technology Co., Ltd., a high-tech solution designed to transform your welding, cutting, and cleaning tasks. This versatile, all-in-one device combines advanced laser technology with a user-friendly design, making it a powerful tool for a wide range of applications, from industrial manufacturing to household projects.

Why Choose Our Laser Welder?

Exceptional Performance: Our handheld laser welder uses a 1000–2000 watt fiber laser to deliver high electro-optical conversion efficiency and superior beam quality, resulting in more uniform weld spots and deeper penetration. It's especially effective for welding ultra-thin parts that are typically difficult to work with using traditional methods like argon arc welding.

Maintenance-Free Operation: Say goodbye to frequent adjustments and high operational costs. Our machine is designed to be maintenance-free, with low power consumption and no consumables, which significantly reduces long-term processing costs.

User-Friendly Design: The compact and highly integrated design, complete with built-in air cooling, makes it flexible and easy to use. The operation is so simple that you don't need to be an experienced technician to get started.

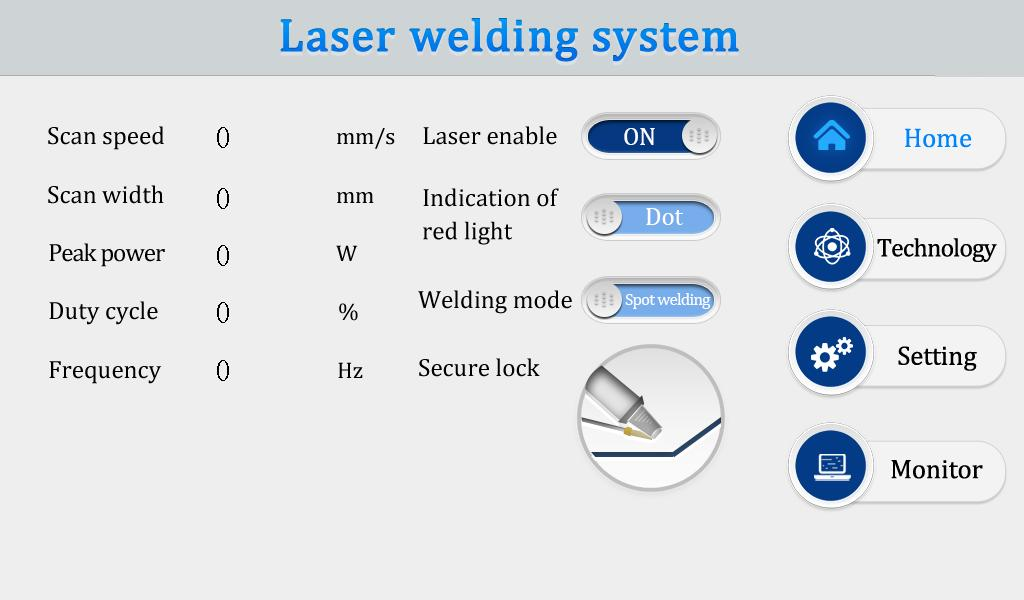

Enhanced Safety: The machine features a safety protection upgrade that restricts laser emission to metal surfaces only. For additional security, a safety ground lock requires the welding head to be in contact with the workpiece before the laser can be activated, preventing accidental light output and potential injury.

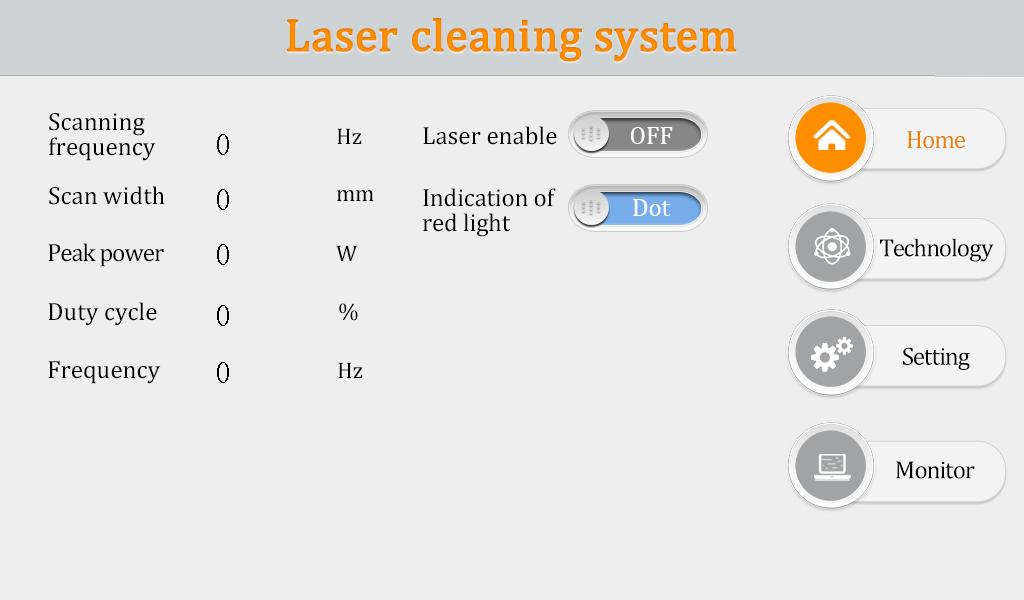

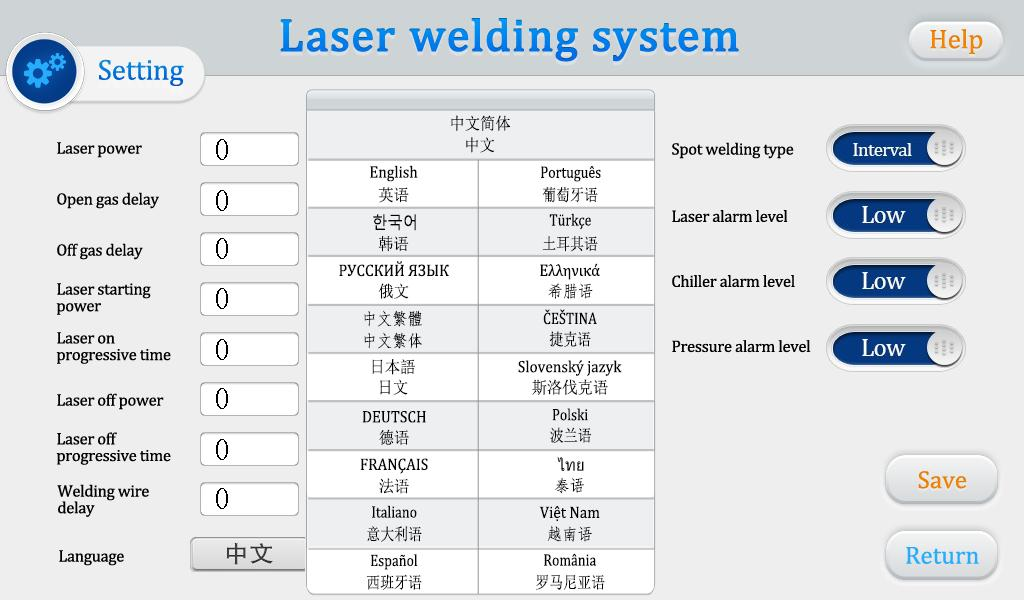

Global Accessibility: Our intuitive interface supports more than 20 languages, making the machine accessible to a global workforce and enabling seamless operation for users worldwide.

Product Parameters

| Parameter Category | Parameter Name |

Details & Specifications

|

|

Laser & Performance

|

Laser Type |

1000–2000 watt fiber laser

|

| Electro-Optical Efficiency |

High conversion efficiency

|

|

| Beam Quality |

Superior, fiber-transmitted

|

|

| Oscillation Amplitude |

0mm to 6mm, adjustable via PLC control system

|

|

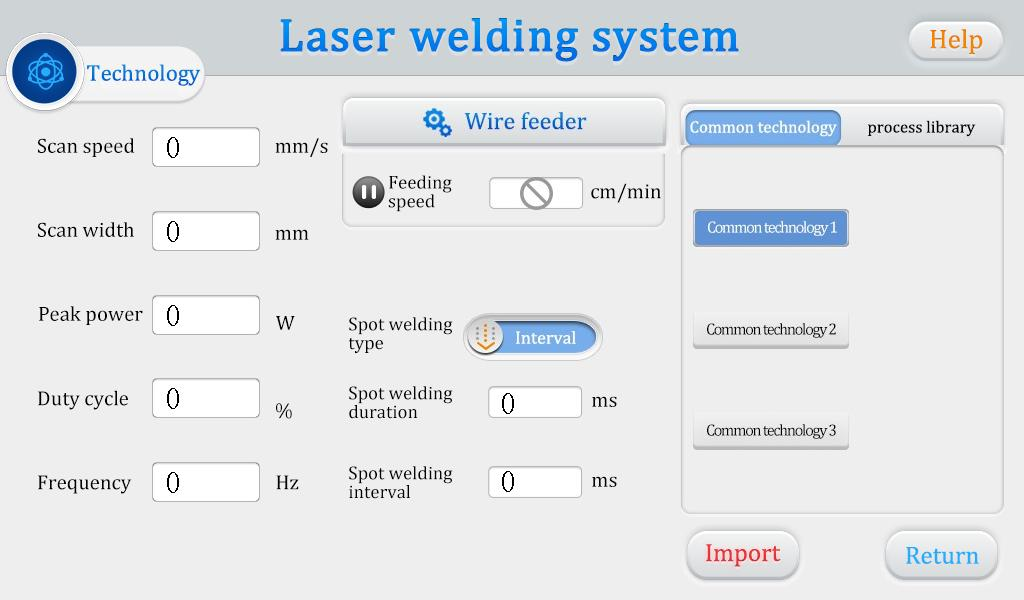

| Scan Speed (Welding) |

2–6000 mm/s (common speed is 300 mm/s)

|

|

| Scan Width (Welding) |

0–6 mm (common width is 2.5–4 mm)

|

|

| Peak Power |

Must be less than or equal to the laser power on the settings page

|

|

| Duty Cycle |

0–100% (default: 100%)

|

|

| Pulse Frequency |

Recommended range: 5–5000 Hz (default: 2000 Hz)

|

|

|

Operational Modes

|

Supported Modes |

Welding, Cutting, and Cleaning

|

| Welding Modes |

Continuous and Spot welding

|

|

| Scan Width (Cleaning) |

0–30 mm (with F150 focusing lens)

|

|

|

Electrical & Environment

|

Power Supply |

220VAC ±10%, 6kW total power

|

| Power Breaker |

Requires a C32 air circuit breaker with leakage protection

|

|

| Workroom Temperature | 0°C to 40°C | |

| Workroom Humidity |

<60%, non-condensing

|

|

| Power Status Monitoring |

Displays 24V, ±15V supply voltages and currents

|

|

|

Safety Features

|

Laser Emission |

Restricted to metal surfaces only

|

| Safety Ground Lock |

Requires the welding head to be in contact with the workpiece for laser activation

|

|

| Class |

Class 4 laser product

|

|

| Safety Warnings |

Warns of high voltage, laser radiation, and fire hazards

|

|

|

Design & Usability

|

Handheld Head |

Equipped with a 10-meter imported optical fiber

|

| Design |

Compact and highly integrated, with built-in air cooling

|

|

| Interface Languages |

Supports 19 languages in the standard version

|

|

| User Skill Level |

Simple to operate; no experienced technician required

|

|

|

Maintenance

|

Cleaning |

Wipe external components, protective lens, and keep the environment dust-free

|

| Cooling System |

Regularly inspect and clean dust from the air duct

|

|

| Wearing Parts |

Protective lens and copper nozzle

|

|

| Maintenance Frequency |

Daily and half-yearly checks recommended

|

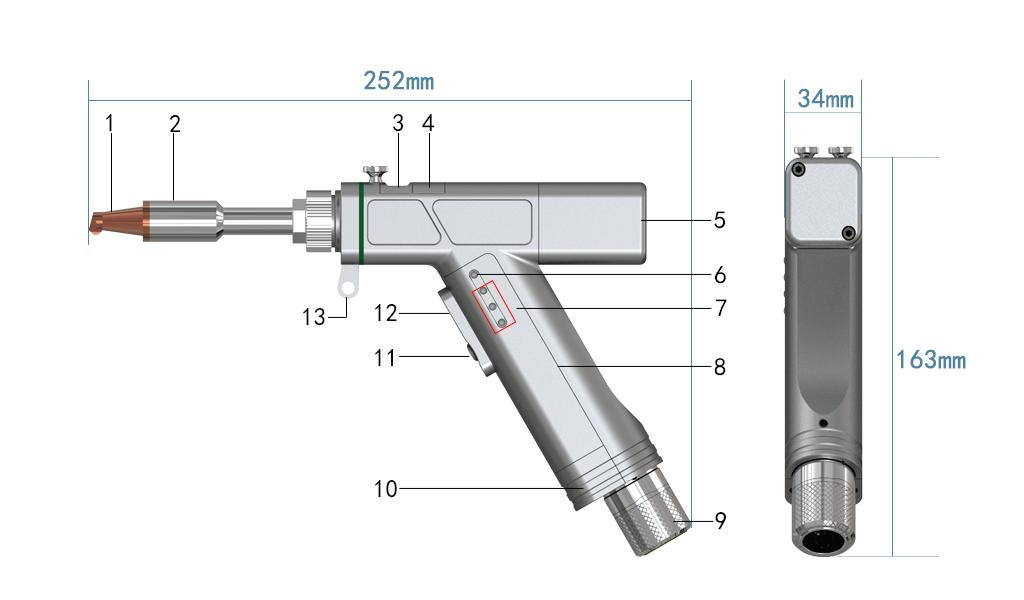

Laser Welding Head

Home Page