- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

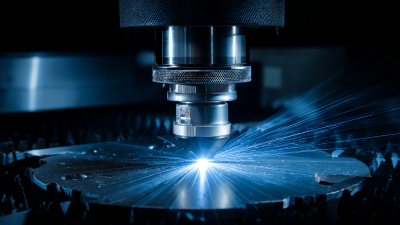

The Ultimate Guide to Choosing the Right Industrial Laser Machine for Your Production Needs

Table of Contents

- Understanding Different Types of Industrial Laser Machines for Your Needs

- Key Factors to Consider When Choosing a Laser Machine for Production

- Evaluating Material Compatibility: Which Laser Works Best for Your Products?

- Analyzing Cost vs. Performance: Finding the Right Balance in Laser Selection

- Tips for Maintenance and Longevity of Your Industrial Laser Investment

- Exploring Future Trends in Industrial Laser Technology for Smarter Choices

- FAQS

- Conclusion

- Related Posts

In recent years, the industrial laser machine market has experienced exponential growth, with the global market projected to reach USD 8 billion by 2026, growing at a CAGR of approximately 6.5% from 2021 to 2026. As manufacturers increasingly seek to enhance precision and efficiency in production processes, the demand for advanced laser technologies continues to skyrocket.

Fortune Laser Technology Co., Ltd., founded in 2016 and headquartered in Shenzhen city, is at the forefront of this technological revolution, providing a wide range of laser equipment integrated with R&D, production, sales, and maintenance services. Choosing the right industrial laser machine is crucial for optimizing production capabilities, reducing costs, and ensuring high-quality output, making it essential for businesses to stay informed about the latest advancements and considerations in this dynamic field.

Understanding Different Types of Industrial Laser Machines for Your Needs

When selecting the right industrial laser machine, understanding the different types available is crucial to meet your production needs effectively. Each type of laser machine has distinct characteristics that cater to specific applications. For instance, CO2 lasers are highly versatile and well-suited for cutting, engraving, and marking non-metallic materials such as wood, acrylic, and glass. Their ability to produce a fine, detailed finish makes them a popular choice in industries ranging from sign making to crafting.

On the other hand, fiber lasers are known for their efficiency and high-speed capabilities when working with metals. They are ideal for applications requiring precision and speed, such as cutting stainless steel and aluminum. Additionally, since fiber lasers have a longer lifespan and require less maintenance compared to other types, they present a cost-effective option for many manufacturing processes. Understanding these differences helps manufacturers align their production requirements with the appropriate technology, ultimately enhancing productivity and output quality.

Key Factors to Consider When Choosing a Laser Machine for Production

When selecting the right industrial laser machine for production, several key factors must be considered to meet specific operational needs effectively. Firstly, understanding the different types of laser technologies—such as CO2, solid-state, fiber, and diode lasers—is essential, as each type caters to various materials and applications. For instance, the global fiber laser market is projected to grow from $4.63 billion in 2025 to $10.75 billion by 2032, showcasing a compound annual growth rate (CAGR) of 12.8%. This indicates a rising preference for fiber lasers in precision tasks across industries.

Another critical consideration is the power requirements of the laser machine. Depending on the production needs—be it microprocessing or macroprocessing—the power must be selected accordingly. Machines under 1 kW are suitable for light marking and engraving, while those exceeding 1.1 kW are favored for more extensive cutting and thick material processing. With the global industrial laser market set to expand from $28.51 billion in 2025 to $64.39 billion by 2032, a CAGR of 12.3% reflects the increasing demand for advanced laser machines in manufacturing practices.

Additionally, the application and end-use industry significantly influence the choice of laser machinery. The aerospace, automotive, and electronics sectors are prominent users of CO2 lasers due to their flexibility in processing metals, plastics, glass, and textiles. It is vital for businesses to align their laser machine selection with industry trends and future growth projections, ensuring they invest in equipment that not only meets current demands but is also scalable for future production needs.

Evaluating Material Compatibility: Which Laser Works Best for Your Products?

When selecting an industrial laser machine, assessing material compatibility is critical to optimizing production efficiency and quality. Different laser types—such as CO2, fiber, and solid-state lasers—offer distinct advantages depending on the materials being processed. For instance, CO2 lasers excel in cutting non-metal materials like wood, acrylic, and textiles, making them ideal for industries ranging from signage to fashion. According to a recent industry report by MarketsandMarkets, the CO2 laser market is projected to grow at a CAGR of 5.6% through 2026, largely driven by its versatility with various materials.

On the other hand, fiber lasers have gained popularity in metal processing due to their efficiency and precision. They can cut and engrave materials like stainless steel, aluminum, and brass with high-speed processing capabilities. Research from Grand View Research highlights that the global fiber laser market is expected to reach $7.12 billion by 2027, indicating a robust demand for metalworking applications. Businesses must therefore carefully evaluate the materials they intend to work with, as this directly influences the choice of laser technology and impacts overall production outcomes.

The Ultimate Guide to Choosing the Right Industrial Laser Machine for Your Production Needs

| Material Type | Laser Type | Power (W) | Cutting Speed (mm/s) | Thickness Capability (mm) |

|---|---|---|---|---|

| Acrylic | CO2 Laser | 40-150 | 200-600 | 1-20 |

| Metal | Fiber Laser | 500-3000 | 100-2000 | 0.5-25 |

| Wood | CO2 Laser | 60-150 | 100-400 | 1-30 |

| Ceramics | CO2 Laser | 80-200 | 50-150 | 1-10 |

Analyzing Cost vs. Performance: Finding the Right Balance in Laser Selection

When selecting an industrial laser machine, balancing cost and performance is crucial for optimizing production efficiency. A recent report from Market Research Future indicates that the global industrial laser market is expected to exceed $20 billion by 2025, highlighting the growing demand for high-quality and cost-effective laser solutions. Understanding how to evaluate different machines based on your specific production requirements can significantly impact your bottom line.

Tip: Before making a purchase, conduct a thorough analysis of your production volume and material type. For instance, CO2 lasers are particularly effective for cutting non-metal materials, while fiber lasers offer superior performance for metals. Depending on your needs, the difference in initial investment can be justified by the operational savings and longevity of the equipment.

Moreover, consider the total cost of ownership (TCO), which encompasses not just the initial price but also maintenance, consumables, and energy consumption. According to a study by the International Energy Agency, lasers that are energy-efficient can reduce operational costs by up to 30%. Evaluate machines based on their operational efficiency, which can save substantial resources over time.

Tip: Collaborate with suppliers to gauge the long-term benefits of using their equipment versus the purchase price. Gathering testimonials or case studies from similar industries can also provide insights into performance benchmarks that can guide your decision-making process.

Tips for Maintenance and Longevity of Your Industrial Laser Investment

Maintaining your industrial laser machine is crucial for ensuring its longevity and optimal performance. Regular maintenance not only prevents costly repairs but also enhances the efficiency of your production processes. One key tip is to establish a routine inspection schedule. Checking critical components such as the lens, mirrors, and cooling systems can help you identify any potential issues before they escalate. Clean these parts using a gentle, non-abrasive cleaner to avoid scratches that could affect the quality of your work.

Another valuable tip is to ensure that your operator is properly trained and aware of the machine's functionalities. Misuse can lead to excessive wear and tear, so providing continuous education and training can mitigate risks. Additionally, keep a log of your maintenance activities, including replacement parts and any adjustments made. This documentation allows you to track the machine's performance over time and can inform future maintenance strategies that enhance its lifespan.

Exploring Future Trends in Industrial Laser Technology for Smarter Choices

As the industrial landscape continues to evolve, the right choice of laser technology becomes increasingly critical for manufacturers seeking efficiency and precision.

Future trends in industrial laser technology highlight the shift towards smart, data-driven applications that integrate seamlessly with automation and IoT systems.

This integration not only enhances operational capabilities but also optimizes production processes, thus positioning businesses to respond swiftly to market demands.

With advancements such as artificial intelligence and machine learning at the forefront, laser machines are becoming more adaptive and user-friendly.

These innovations empower manufacturers to automate complex tasks, significantly reducing manual intervention and minimizing errors. Furthermore, the growth in applications—ranging from laser cutting to cleaning—demonstrates the versatility of laser systems in various industries.

As companies gear up for 2025, it is paramount for them to stay ahead by investing in cutting-edge laser technology that not only meets current production needs but also aligns with future trends in smart manufacturing.

FAQS

: CO2 lasers are highly versatile and well-suited for cutting, engraving, and marking non-metallic materials such as wood, acrylic, and glass.

Fiber lasers are known for their efficiency and high-speed capabilities, particularly when cutting metals like stainless steel and aluminum.

Fiber lasers have a longer lifespan and require less maintenance, making them a cost-effective option for many manufacturing processes.

Industrial laser technology is shifting towards smart, data-driven applications that integrate with automation and IoT systems, enhancing operational capabilities.

AI and machine learning advancements make laser machines more adaptive and user-friendly, allowing manufacturers to automate complex tasks and reduce manual intervention.

Manufacturers should be aware that investing in cutting-edge laser technology that meets current production needs and aligns with future trends in smart manufacturing is essential.

Lasers are utilized in a variety of industries for applications ranging from laser cutting to cleaning, demonstrating their versatility.

Integration with smart manufacturing technologies optimizes production processes, enabling businesses to respond swiftly to market demands.

Companies should invest in advanced laser technology to keep up with evolving manufacturing needs and leverage future trends in smart manufacturing.

Conclusion

Choosing the right Industrial Laser Machine for your production needs involves a comprehensive understanding of various types of machines and their specific applications. This guide emphasizes key factors such as material compatibility, cost versus performance, and the importance of maintenance to ensure longevity. Evaluating which laser technology aligns with your product requirements is crucial for maximizing efficiency and output.

As we explore future trends in industrial laser technology, businesses can make smarter choices that not only enhance their production capabilities but also adapt to evolving market demands. At Fortune Laser Technology Co., Ltd., we combine our extensive expertise in R&D, production, and maintenance services to offer innovative solutions tailored to meet the needs of diverse industries.

Related Posts

-

Exploring the Versatile Applications of Best Industrial Laser Cutting Equipment in Aerospace and Automotive Industries

-

What is the Best CNC Laser Machine? A Comprehensive Overview with Industry Insights and Data

-

7 Key Advantages of Using High Power Laser Cutters in Modern Manufacturing

-

Finding Top Suppliers for Best 3015 Fiber Laser Cutter Your Essential Checklist Guide

-

5 Key Features to Look for in the Best Metal Laser Cutting Equipment

-

The Ultimate Guide to Choosing the Best Fiber Laser Cutting Equipment for Your Business Needs

Blog Tags: