- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

Top 5 Tips for Using a Pulsed Laser Cleaning Machine?

Table of Contents

- Understanding the Basics of Pulsed Laser Cleaning Technology

- Identifying Suitable Materials for Laser Cleaning Applications

- Preparing the Surface for Effective Laser Cleaning

- Adjusting Laser Settings for Optimal Results

- Safety Precautions When Operating a Pulsed Laser Cleaning Machine

- Maintaining and Troubleshooting Your Laser Cleaning Equipment

- Exploring Advanced Techniques for Enhanced Laser Cleaning Efficiency

- A Comprehensive Guide to the FL-C300N 200/300W Portable Pulse Laser Cleaning Machine: Innovations and Applications

- FAQS

- Conclusion

- Related Posts

Using a Pulsed Laser Cleaning Machine really marks a big step forward in industrial cleaning tech. Dr. Emily Carter from LaserTech Innovations puts it nicely when she says, 'Precision cleaning isn't just about being effective; it actually changes how maintenance gets done.' That comment shows just how game-changing this equipment can be across different fields.

Now, if you're working with a Pulsed Laser Cleaning Machine, it's super important to understand what it does best—and where it might fall short. Every machine has its own settings that can boost performance, but if you don’t use them right, results can be less than stellar. Remember, even though this tech packs a punch, you gotta handle it with care to avoid mistakes.

And honestly, even experienced folks sometimes miss small but crucial details. Every cleaning job comes with its own quirks and challenges. Rushing through can lead to cleaning that’s not thorough enough or even cause damage to the equipment. So, taking your time, knowing your stuff, and thinking things through really makes all the difference. If you embrace both what this tech can do and what to watch out for, you’re much more likely to get great results in the end.

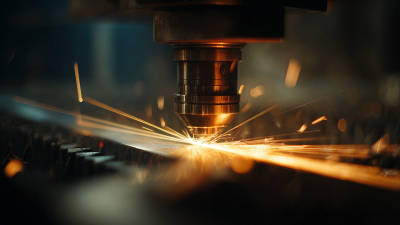

Understanding the Basics of Pulsed Laser Cleaning Technology

Pulsed laser cleaning technology is becoming increasingly popular in various industries. This method uses high-intensity laser beams to remove unwanted materials from surfaces. It’s effective for cleaning metals, plastics, and even delicate materials. A recent industry report indicated that the pulsed laser cleaning market is projected to grow at a compound annual growth rate (CAGR) of 8.3% through 2026. This reflects a rising interest in sustainable and effective cleaning methods.

Understanding how this technology works is crucial. Laser cleaning relies on photonic energy. Essentially, the laser pulses create heat that dislodges contaminants. This process can be precise, reducing the risk of damaging underlying surfaces. However, operators must be cautious. Overuse can lead to unintended surface degradation. The cleaning process can also be time-consuming, particularly for extensive areas or stubborn contaminants.

Moreover, safety considerations are vital. Proper eyewear and protective gear are necessary. The high energy of laser beams poses risks. Analysts suggest that training is essential to ensure effective use, yet many operators may lack adequate experience. Investing in comprehensive training programs could mitigate risks and improve outcomes. Addressing these aspects will enhance the overall effectiveness of pulsed laser cleaning machines in diverse applications.

Top 5 Tips for Using a Pulsed Laser Cleaning Machine

| Tip | Description | Benefits |

|---|---|---|

| 1. Understand Material Compatibility | Ensure the material you intend to clean is suitable for laser cleaning. | Prevents damage and maximizes cleaning efficiency. |

| 2. Adjust Laser Parameters | Set appropriate power, frequency, and pulse duration for the task. | Enhances performance and optimizes results. |

| 3. Maintain Equipment Regularly | Schedule routine maintenance for reliable performance and longevity. | Reduces downtime and maintenance costs. |

| 4. Safety First | Use proper protective gear and ensure a safe working environment. | Minimizes risk of accidents and injuries. |

| 5. Test on a Small Area | Conduct a test on an inconspicuous area before full application. | Ensures desired results and mitigates potential issues. |

Identifying Suitable Materials for Laser Cleaning Applications

When using a pulsed laser cleaning machine, it's crucial to identify suitable materials for effective applications. Laser cleaning technology excels in removing contaminants from metals, ceramics, and some plastics. In the aerospace and automotive industries, approximately 30% of maintenance processes involve surface cleaning. Laser cleaning not only shortens these operations but also ensures minimal damage to underlying materials.

The most commonly cleaned materials include stainless steel, aluminum, and carbon steel. According to a recent industry report, these metals exhibit over 90% effectiveness in laser cleaning scenarios. However, some composites may not respond well. High-performance plastics, for instance, can warp under intense laser energy. Each material has specific reflecting and absorption properties. So, testing is essential before full-scale applications.

Understanding the limitations of laser cleaning is equally important. Not all coatings or contaminants can be effectively removed. For example, certain polymers might absorb harmful levels of laser energy, risking the integrity of the material. Furthermore, environmental factors, such as humidity and temperature, can affect cleaning efficiency. Always factor these aspects into the cleaning strategy to avoid unexpected challenges.

Preparing the Surface for Effective Laser Cleaning

Preparing the surface before using a pulsed laser cleaning machine is crucial for optimal results. Start by removing any loose debris from the area. Sweeping or vacuuming can help eliminate dust and larger particles. This initial step can make a significant difference. A clean surface allows the laser to interact effectively with contaminants.

Next, assess the material that needs cleaning. Different surfaces have unique properties and may react differently to laser cleaning. For example, metals and plastics respond in varied ways. Take time to test the laser on a small, inconspicuous spot. This approach helps to gauge effectiveness and adjust the settings accordingly.

Consider the angle of laser application. The optimal angle can enhance cleaning efficiency. Experimenting with various distances also provides insights. Sometimes, the ideal distance might not be what you expect. These small adjustments can lead to better outcomes. Be open to learning from the process, as it often requires trial and error.

Adjusting Laser Settings for Optimal Results

Adjusting laser settings is crucial for achieving optimal results with a pulsed laser cleaning machine. Each material responds differently to laser power and frequency. Too high a power setting can damage the substrate. Too low may not effectively remove contaminants. Start by assessing the surface to determine the right balance.

Tip 1: Conduct a test run on a small area. This step helps gauge the effect of your settings. Monitor the material closely. If it begins to discolor or warp, lower the power. Use this feedback for adjustments.

Tip 2: Adjust the pulse duration according to the type of soiling. Oily residues might need longer pulses, while lighter dust can be cleaned quickly. Pay attention to the thickness of the material as well; thicker surfaces often require more energy and time.

Tip 3: Keep the laser nozzle at an optimal distance. Too far can reduce efficiency, while too close may cause damage. You must find a sweet spot. Always observe the cleaning process. This will guide your future adjustments and ensure you get the best results without compromising the material's integrity.

Safety Precautions When Operating a Pulsed Laser Cleaning Machine

When operating a pulsed laser cleaning machine, safety must be a top priority. Always wear suitable protective gear. A laser safety helmet is essential. Protective gloves and full-face shields help prevent injuries. Your eyes are particularly vulnerable. Don't forget to check your work area for reflective surfaces. These can bounce the laser back towards you, causing harm.

Before starting, ensure the area is well-ventilated. Laser cleaning can release hazardous particles. A proper exhaust system can minimize health risks. Train operators thoroughly before they handle the equipment. Improper use can lead to severe accidents. Encourage a buddy system where experienced users mentor others. Teamwork can enhance safety.

Stay vigilant for any unusual signs. If the machine makes strange noises or vibrations, turn it off immediately. Regular maintenance is also crucial. Clean and inspect components as needed. Ignoring small issues can lead to big problems. Respecting these precautions will ensure a safer working environment. Use the technology wisely and responsibly.

Maintaining and Troubleshooting Your Laser Cleaning Equipment

Maintaining your pulsed laser cleaning equipment is crucial for optimal performance. Regular inspections can prevent unexpected breakdowns. Check for any signs of wear in the laser lenses. Even small scratches can affect functionality. Dust accumulation can also hinder performance. A clean lens ensures that maximum power is delivered during operation.

Troubleshooting often begins with understanding common issues. If the laser power seems reduced, it might be time to recalibrate. Sometimes, settings get off track due to user error or software glitches. Keep your manual handy for guidance. Don't ignore unusual noises or error codes. These could indicate underlying problems needing immediate attention. Pay attention to your equipment's performance after maintenance.

Proper storage is just as important. Store your machine in a dry, temperature-controlled environment. This avoids moisture and extreme temperatures, which can impact components. Remember, neglecting maintenance leads to inefficiency. Regularly review your cleaning methods. There’s always room for improvement, so stay engaged with your equipment.

Top 5 Tips for Using a Pulsed Laser Cleaning Machine

This chart illustrates the effectiveness of different maintenance tips for improving the performance of pulsed laser cleaning machines. The data represents a percentage of users who found the tips beneficial based on a survey.

Exploring Advanced Techniques for Enhanced Laser Cleaning Efficiency

Using a pulsed laser cleaning machine can be highly effective when approached with advanced techniques. Start by selecting the right settings for your specific cleaning project. Adjusting the pulse frequency and duration can make a noticeable difference. Too fast or too slow can impact cleaning efficiency. Sometimes, the cleaning may not be as thorough as expected. Experimenting with different settings might be necessary.

Observing the material being cleaned is crucial. Some surfaces may react differently than anticipated. For example, softer materials may sustain damage if the laser intensity is too high. It's wise to test on small areas first. You might notice uneven cleaning or unexpected damage in initial tests. This reflects the need for more refined techniques in applying the laser.

Consider the environment where cleaning takes place. Dust, humidity, and temperature can all affect laser performance. A controlled environment often yields better results. Inadequate conditions may lead to inefficiencies. Reflections from nearby surfaces can also impact the laser’s effectiveness. Assessing these factors ensures that each cleaning session is as efficient as possible. Always be open to tweaking your approach based on past experiences.

A Comprehensive Guide to the FL-C300N 200/300W Portable Pulse Laser Cleaning Machine: Innovations and Applications

The FL-C300N 200/300W Portable Pulse Laser Cleaning Machine represents a groundbreaking advancement in the field of surface treatment technology. This innovative portable device is engineered to effectively eliminate rust, paint, oil, and various coatings, ensuring the underlying material remains unscathed. With its precise, non-contact operation, the FL-C300N sets a new standard for efficiency and safety, making it an ideal solution for a variety of cleaning applications across multiple industries.

In today’s fast-paced work environments, the demand for high-performance cleaning solutions has never been greater. The FL-C300N addresses this need by providing not only an environmentally friendly alternative to traditional cleaning methods but also a level of precision that minimizes the risk of damage. Users can now rejuvenate surfaces with confidence, knowing that this powerful tool combines advanced technology with ease of use. Whether in workshops, manufacturing facilities, or restoration projects, the FL-C300N is poised to revolutionize the way surfaces are treated and cleaned.

FAQS

: Begin small. Pick one action. Keep it simple. Repeat daily.

Set specific goals. Track your progress. Celebrate small wins.

Reflect on what happened. Adjust your approach. Try again without guilt.

Consistency builds routine. It reinforces your commitment. Even small steps matter.

Yes, adapt as needed. Life changes often. Flexibility can lead to better results.

Identify what distracts you. Create a focused environment. Limit interruptions as much as possible.

Absolutely, setbacks happen to everyone. Use them as learning opportunities. Stay committed to your goals.

Regularly check in. Weekly or monthly reviews can help. Adjust your strategy based on outcomes.

Results take time. Trust the process. Focus on your efforts, not just outcomes.

Connect with others who share your goals. Join groups or online communities. Support systems help keep you accountable.

Conclusion

The article "Top 5 Tips for Using a Pulsed Laser Cleaning Machine" provides essential guidance for effectively utilizing this innovative cleaning technology. It begins by outlining the fundamental principles of pulsed laser cleaning, emphasizing its application to various materials. Proper preparation of the surface is crucial for achieving optimal cleaning results, along with adjusting the laser settings accordingly.

Safety is highlighted as a top priority when operating a Pulsed Laser Cleaning Machine, with recommendations for protective measures. Additionally, the article covers maintenance and troubleshooting tips to ensure the equipment remains in peak condition. Lastly, it explores advanced techniques that can further enhance the efficiency of laser cleaning processes, making this guide a valuable resource for both novices and experienced users alike.

Related Posts

-

Revolutionizing Surface Restoration with High Power Laser Cleaning Technology

-

Top 10 Benefits of Laser Cleaning High Power Technology for Your Industry

-

Top Benefits of Large Format Laser Cleaning Machines for Industrial Application

-

What is the Technology Behind Industrial Laser Cleaning Machines and Its Impact on Efficiency

-

Top 10 Tips for Using a Handheld Laser Cleaner Effectively

-

Top 10 Benefits of Using a Laser Paint Cleaning Machine?