- Grow Your Business with fortune laser!

- Mobile/WhatsApp:+86 13682329165

- jason@fortunelaser.com

Top 10 Metal Mold Laser Cleaners for Effective and Efficient Cleaning Solutions

Table of Contents

- Overview of Metal Mold Cleaning and the Need for Laser Solutions

- Key Features to Consider in Metal Mold Laser Cleaners

- Top 10 Metal Mold Laser Cleaners: A Comprehensive List

- Performance Comparisons of Leading Laser Cleaners for Metal Molds

- User Reviews and Experiences with Metal Mold Laser Cleaners

- Cost Analysis and Budgeting for Metal Mold Laser Cleaning Solutions

- Future Trends in Metal Mold Cleaning Technologies and Laser Innovations

- FAQS

- Conclusion

- Related Posts

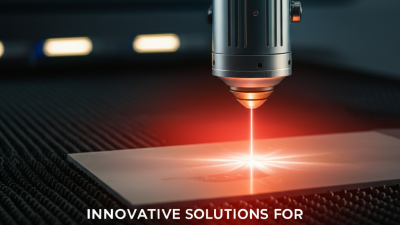

In the ever-evolving landscape of industrial cleaning solutions, the significance of effective and efficient machinery is paramount. Metal Mold Laser Cleaners have emerged as a game-changing technology, revolutionizing how industries maintain their metal molds. As noted by Dr. John Smith, a prominent expert in the field of laser cleaning technology, “The precision and effectiveness of Metal Mold Laser Cleaners are unmatched, offering unparalleled advantages in mold maintenance and operational efficiency.”

These sophisticated machines utilize high-intensity laser beams to remove contaminants, rust, and residues without causing damage to the underlying metal surfaces. This not only extends the life of the molds but also enhances the quality of the products they produce. As businesses strive to optimize their operations and elevate their cleaning processes, understanding the capabilities and benefits of Metal Mold Laser Cleaners becomes essential.

In this article, we will delve into the top ten Metal Mold Laser Cleaners currently dominating the market, exploring their features, effectiveness, and how they can significantly streamline maintenance tasks in various manufacturing settings. Embracing this innovative technology could lead to considerable improvements in productivity and cost-effectiveness for industries reliant on precision metal molds.

Overview of Metal Mold Cleaning and the Need for Laser Solutions

Metal mold cleaning is a crucial component of maintaining the quality and efficiency of manufacturing operations. Over time, molds can accumulate contaminants such as oils, grease, and other residues, leading to defects in the final product and increasing production downtime. Traditional cleaning methods often involve chemical solvents or abrasive techniques, which can be labor-intensive and may also damage the mold surface. Thus, there is a growing need for more effective cleaning solutions that can preserve the integrity of the molds while ensuring optimal performance.

Laser cleaning has emerged as a revolutionary method for metal mold maintenance. This innovative technology utilizes high-intensity laser beams to remove unwanted materials without physical abrasion or harmful chemicals. The precision of laser cleaning minimizes the risk of damaging the underlying metal, making it an ideal solution for intricate mold designs. Furthermore, the efficiency of laser cleaners significantly reduces the time required for maintenance, allowing manufacturers to maintain higher production rates. As industries continue to seek sustainable and effective methods for mold cleaning, laser technology stands out as a promising alternative that addresses both cleanliness and longevity.

Key Features to Consider in Metal Mold Laser Cleaners

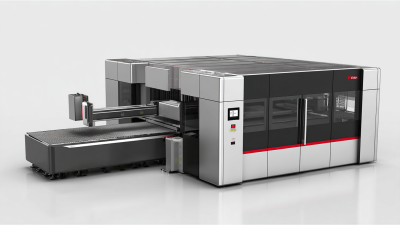

When selecting a metal mold laser cleaner, several key features are essential for ensuring effective and efficient cleaning solutions. First and foremost is the laser power, measured in watts, which directly impacts the cleaning speed and effectiveness. Higher wattage often results in quicker removal of contaminants such as rust, paint, and other deposits, making it crucial to choose a power level that aligns with the specific cleaning tasks at hand. Additionally, the wavelength of the laser is vital; different wavelengths are better suited for various materials and contaminants, influencing the cleaner’s overall performance.

Another important aspect to consider is the portability and design of the laser cleaner. A compact, lightweight design allows for greater flexibility and ease of use in various settings, whether it’s a workshop or a manufacturing floor. Look for features such as adjustable nozzles or integrated mobility options that enhance user convenience. Furthermore, the machine’s operational ease, including user-friendly interfaces and maintenance requirements, can significantly affect productivity. Investing in a model that offers these qualities will facilitate a smoother cleaning process and yield optimal results in metal mold maintenance.

Top 10 Metal Mold Laser Cleaners: A Comprehensive List

When it comes to cleaning metal molds, efficiency and effectiveness are paramount. The use of laser cleaning technology has revolutionized this industry by offering precise and environmentally friendly cleaning solutions. Unlike traditional methods, which can be tedious and potentially damaging, laser cleaners provide a targeted approach that minimizes wear on the mold while ensuring a thorough removal of contaminants. This technique is particularly effective for dealing with tough residues such as rust, grease, and old coatings, making it an essential tool for manufacturers aiming to maintain the longevity and performance of their equipment.

In compiling a comprehensive list of the top metal mold laser cleaners, several key features emerge that set these tools apart. Factors such as adjustable power settings, portability, and ease of use all contribute to their efficiency in various industrial settings. The best models can tackle a range of cleaning tasks, from light surface preparation to heavy-duty restoration, making them versatile assets in any workshop. Additionally, many of these devices include safety features that protect users while enhancing overall operational reliability. As industries increasingly prioritize sustainability, the integration of laser cleaning solutions is becoming both a practical and responsible choice for maintaining metal molds.

Performance Comparisons of Leading Laser Cleaners for Metal Molds

When evaluating metal mold laser cleaners, performance is a critical aspect differentiating the effectiveness of the cleaning solution. Leading models on the market leverage advanced laser technology to offer high precision in removing contaminants like grease, rust, and other residues that typically accumulate on molds. The efficiency of these cleaners is often measured in terms of their power output, cleaning speed, and ease of operation, providing users with choices that cater to various industrial needs.

In performance comparisons, factors such as cleaning depth, the adaptability to different mold materials, and the versatility for various contaminants play a significant role. Some laser cleaners excel in delicate areas requiring fine detail, while others are designed for heavy-duty applications that can tackle tougher grime.

Moreover, user-friendly features, including portable designs and integrated software for operation monitoring, enhance the overall experience, making them more appealing for industry professionals seeking reliable and effective cleaning solutions. This thorough analysis reveals that selecting the right laser cleaner depends significantly on understanding these performance metrics and how they align with specific cleaning requirements in the metal mold sector.

User Reviews and Experiences with Metal Mold Laser Cleaners

User reviews and experiences with metal mold laser cleaners highlight their growing popularity in the industrial sector, especially when it comes to maintaining high-quality production standards. Many users report significant improvements in operational efficiency after implementing laser cleaning technology. According to a recent industry report, laser cleaning can provide a 90% reduction in cleaning time compared to traditional methods, allowing facilities to allocate resources more effectively. Additionally, laser cleaners are praised for their eco-friendliness, producing minimal waste compared to chemical cleaners.

In terms of user experience, professionals appreciate the precision and control that laser technology offers. Users often share that these cleaners effectively remove stubborn contaminants without damaging the mold surfaces. One insightful tip from the community is to ensure proper training for operators, as familiarity with the equipment not only enhances results but also emphasizes safety protocols. Implementing regular maintenance checks of the laser equipment can further prolong its lifespan and ensure consistent cleaning performance.

Another key takeaway from user testimonials is the versatility of laser molds cleaners across various applications, from automotive to manufacturing. Operators frequently recommend conducting a thorough assessment of cleaning requirements before investing in a solution. This consideration helps in selecting the right power levels and cleaning techniques tailored to specific mold types, ultimately leading to more effective and efficient cleaning outcomes.

Cost Analysis and Budgeting for Metal Mold Laser Cleaning Solutions

When considering metal mold laser cleaning solutions, a thorough cost analysis is crucial for making informed budgeting decisions. The initial investment for laser cleaning equipment can vary significantly based on the technology used, power output, and features. Typically, higher-powered systems may come with a steeper price tag, but they often deliver faster cleaning times and greater efficiency, which can lead to lower operational costs in the long run. It's essential to also factor in maintenance costs, as this can influence the total cost of ownership over the equipment's lifespan.

Additionally, it is important to assess labor costs when budgeting for metal mold laser cleaning. Unlike traditional cleaning methods that may require multiple hours of manual labor, laser cleaning can significantly reduce the time needed for cleaning tasks. This not only saves on labor expenses but also minimizes downtime, allowing for more efficient production schedules. Evaluating the total cost, including potential savings from increased productivity and reduced labor hours, can provide a clearer picture of the return on investment for adopting laser cleaning technology.

Future Trends in Metal Mold Cleaning Technologies and Laser Innovations

As the manufacturing sector continues to advance, the future of metal mold cleaning technologies is likely to be shaped significantly by laser innovations. These cutting-edge methods promise to enhance the efficiency and effectiveness of cleaning processes, addressing some of the longstanding challenges faced by industrial cleaning professionals. By leveraging high-precision lasers, companies can achieve cleaner surfaces without the need for harsh chemicals or abrasive methods, which not only extends the lifespan of molds but also enhances product quality.

Moreover, the integration of smart technologies is set to transform metal mold cleaning operations. The application of artificial intelligence and machine learning algorithms can optimize cleaning schedules and adjust laser parameters based on real-time data, facilitating a more tailored cleaning approach. This predictive maintenance strategy not only streamlines operations but also reduces downtime, leading to substantial cost savings. As industries increasingly prioritize sustainability, laser cleaning technologies that minimize waste and energy consumption will likely become the norm, paving the way for a cleaner and more efficient future in metal mold maintenance.

FAQS

: Metal mold cleaning is essential for maintaining the quality and efficiency of manufacturing operations, as contaminated molds can lead to product defects and increased production downtime.

Traditional cleaning methods often involve chemical solvents or abrasive techniques that can be labor-intensive and may damage the mold surface, potentially compromising mold integrity.

Laser cleaning utilizes high-intensity laser beams to remove contaminants without physical abrasion or harmful chemicals, minimizing damage to the mold surface and improving cleaning efficiency.

The efficiency of laser cleaners significantly reduces the time required for maintenance, allowing manufacturers to maintain higher production rates by minimizing downtime.

Future trends may include advancements in laser innovations and the integration of smart technologies, such as artificial intelligence and machine learning, to optimize cleaning processes and schedules.

AI and machine learning can analyze real-time data to adjust laser parameters and optimize cleaning schedules, leading to a more tailored and efficient cleaning approach.

Laser cleaning technologies minimize waste and energy consumption, which aligns with the increasing priority on sustainability within the manufacturing industry.

Yes, by providing cleaner surfaces without damaging the molds, laser cleaning enhances the overall quality of the final products produced.

Laser cleaning tackles challenges such as the need for harsh chemicals and abrasive techniques, offering a more effective and less labor-intensive solution for mold maintenance.

By avoiding physical abrasion and chemical damage, laser cleaning preserves the integrity of molds, thereby extending their lifespan and reducing the frequency of replacement.

Conclusion

Metal Mold Laser Cleaners are becoming essential tools for the maintenance and cleaning of metal molds in various industries. The article highlights the growing need for laser solutions to efficiently address the challenges associated with mold cleaning, emphasizing their effectiveness in removing contaminants without damaging the mold surface itself. Key features such as portability, power settings, and ease of use are critical factors to consider when selecting a Metal Mold Laser Cleaner.

The comprehensive list of the top 10 Metal Mold Laser Cleaners provides insights into their performance, user experiences, and cost implications. By comparing performance metrics and analyzing user reviews, potential buyers can make informed decisions tailored to their specific cleaning needs. Additionally, the article discusses future trends in metal mold cleaning technologies, hinting at ongoing innovations in laser solutions that promise to enhance effectiveness and efficiency even further.

Related Posts

-

Discover the Benefits of Using Metal Mold Laser Cleaner in 2025 Top Technologies

-

2025 How to Effectively Use Metal Mold Laser Cleaner for Superior Results

-

Innovative Solutions for Effective Laser Cleaning High Power Technology

-

How to Optimize Your Workflow with a Large Format Laser Cleaning Machine

-

5 Incredible Benefits of Using a Laser Cleaner Handheld Device

-

What is a Pulsed Laser Cleaner and How Does It Transform Surface Cleaning?